Description

Woodward 8237-1600 Product Specification

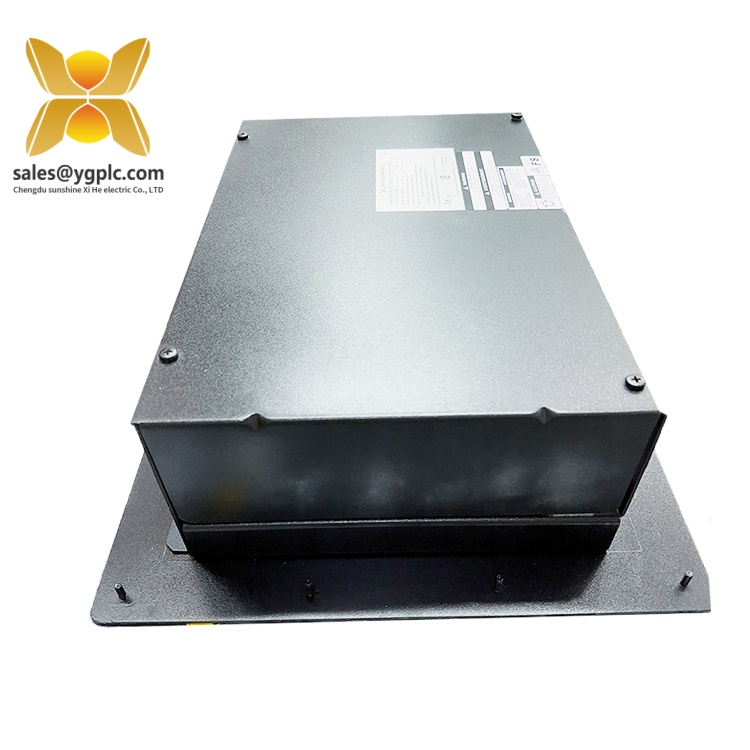

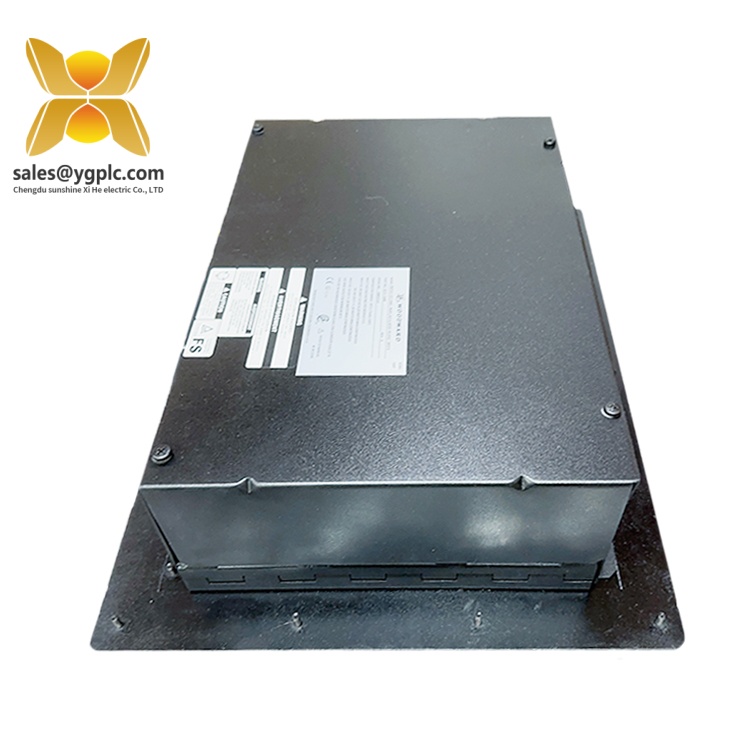

Product Overview:Woodward 8237-1600

The Woodward 8237-1600 is a high-reliability overspeed protection system designed to safeguard steam, gas, and hydraulic turbines, as well as compressors and reciprocating engines, against dangerous overspeed or over-acceleration events. Engineered by Woodward, a global leader in energy control solutions, this module is part of the ProTech-GII platform, renowned for its triple modular redundancy (TMR) architecture and advanced diagnostic capabilities. The Woodward 8237-1600 serves as a critical component in turbine control systems, ensuring safe shutdowns and minimizing downtime across industries such as power generation, oil and gas, and manufacturing.

At its core, the Woodward 8237-1600 integrates three independent control modules, each capable of monitoring turbine speed and acceleration through dedicated magnetic pickup units (MPUs). Using a 2-out-of-3 voting logic, the system accurately detects anomalies and initiates shutdown commands within milliseconds, preventing catastrophic failures. The module supports dual redundant trip relay outputs and features a conformal coating that resists corrosive environments, making it suitable for harsh industrial settings. Its modular design allows for online maintenance, enabling users to replace faulty components without disrupting turbine operations.

In automation systems, the Woodward 8237-1600 acts as a fail-safe layer, complementing primary control systems to enhance overall safety and reliability. It interfaces seamlessly with existing turbine control systems via Modbus communication, providing real-time speed readings and diagnostic data. By combining rapid response times with rugged construction, the Woodward 8237-1600 empowers industries to maintain compliance with safety standards while optimizing equipment performance.Whatsapp:+86 18859254943.

Technical Specifications :Woodward 8237-1600

| Parameter Name | Parameter Value |

|---|---|

| Product Model | Woodward 8237-1600 |

| Manufacturer | Woodward |

| Product Type | Overspeed Protection System |

| Input Voltage | 18–36 VDC (isolated) |

| Communication Interface | Modbus RTU |

| Trip Response Time | < 100 ms |

| Operating Temperature | -22°C to +70°C |

| Humidity | 5%–95% non-condensing |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Shock Resistance | 15 g (IEC 60068-2-27) |

| Certifications | CE, UL |

| Physical Dimensions | 200 mm (W) × 300 mm (H) × 150 mm (D) |

8237-1600

Main Features and Advantages :Woodward 8237-1600

Triple Modular Redundancy (TMR): The Woodward 8237-1600 employs three independent control modules with 2-out-of-3 voting logic, ensuring high fault tolerance and continuous operation even in the event of a single module failure. This architecture minimizes false trips and enhances system integrity.

Rapid Fault Detection: Using advanced algorithms, the module monitors turbine speed derivatives to detect over-acceleration events, providing proactive protection against sudden speed surges. Its trip response time of less than 100 ms ensures critical shutdown commands are executed promptly.

Online Maintenance Capability: The plug-and-play design allows users to replace individual modules while the turbine remains operational, reducing downtime and maintenance costs. Inter-module learning functionality ensures seamless synchronization after component replacement.

Environmental Resilience: The conformal coating on the Woodward 8237-1600 protects against sulfur-based gases (H2S, SO2) and meets IEC 721-3-3 1994 environmental class 3C2, making it suitable for corrosive environments common in oil refineries and chemical plants.

Comprehensive Diagnostics: The system provides real-time speed readings (4–20 mA), fault logs with timestamps, and automatic test routines to verify MPU functionality. These features simplify troubleshooting and support predictive maintenance strategies.

8237-1600

Application Areas :Woodward 8237-1600

The Woodward 8237-1600 is widely deployed in industries where equipment safety and operational continuity are paramount:

-

Power Generation:

- Protects steam and gas turbines in power plants, ensuring grid stability and compliance with safety regulations.

- Monitors turbine speed during startup and load changes, preventing overspeed events that could damage generators or disrupt energy production.

-

Oil and Gas:

- Integrates with compressor stations to manage high-speed rotating equipment, reducing the risk of mechanical failure in upstream and downstream processes.

- Provides fail-safe protection for reciprocating engines in offshore platforms, where downtime costs are extremely high.

-

Manufacturing:

- Controls high-speed production lines, such as those in automotive and pharmaceutical industries, by safeguarding against sudden acceleration in conveyor systems or robotic arms.

- Supports predictive maintenance by analyzing sensor data to identify potential equipment degradation.

-

Water and Wastewater Treatment:

- Manages pump stations and treatment processes, ensuring consistent water quality by preventing overspeed in centrifugal pumps.

- Provides remote monitoring capabilities, enabling operators to address anomalies before they escalate.

Related Products :Woodward 8237-1600

- Woodward 8237-1244: A bulkhead-mounted variant of the Woodward 8237-1600 with identical functionality but designed for panel installation in space-constrained environments.

- Woodward 8237-1245: Features additional discrete inputs for alarm/trip reset commands, making it suitable for complex turbine control systems requiring enhanced operator interaction.

- Woodward 8237-1369: Includes pre-defined test routines for automated periodic system verification, ideal for industries with strict regulatory compliance requirements.

- Woodward 8237-1594: Utilizes TMR architecture with 2-out-of-3 voting logic, offering higher fault tolerance for mission-critical applications.

- Woodward 8237-1656: Optimized for hydro turbines, with specialized algorithms to handle water hammer effects and varying load conditions.

8237-1600

Installation and Maintenance :Woodward 8237-1600

Installation Preparation:

Before installing the Woodward 8237-1600, ensure the following:

Before installing the Woodward 8237-1600, ensure the following:

- Verify the power supply meets the module’s requirements (18–36 VDC ±10%).

- Clean the installation area to prevent dust or debris from affecting MPU connectivity.

- Align the module with the backplane connectors according to the user manual, ensuring secure physical and electrical connections.

Maintenance Recommendations:

- Regularly inspect the module for loose connections or physical damage, particularly in high-vibration environments.

- Perform quarterly diagnostic tests using the built-in automated test routines to validate MPU functionality and trip logic.

- Update firmware periodically to access the latest safety features and performance optimizations.Whatsapp:+86 18859254943.

- Monitor environmental conditions (temperature, humidity) to ensure they remain within specified ranges, as extreme conditions can degrade component performance.

8237-1600

Product Warranty :Woodward 8237-1600

Our company provides a one-year quality warranty for the Woodward 8237-1600, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems.

Note: This product description is based on publicly available technical data and industry applications. For detailed specifications, consult the official Woodward datasheet or contact our technical support team.

ABB PM633 Acquisition card

ABB REF542PLUS Gas turbine card

ABB DSAI130D AI card

ABB CB801 Pulse encoder

TRICONEX DO3401 Eddy current sensor

TRICONEX D28799-005 monitor

TRICONEX DI3361 monitor

TRICONEX DO2401 7400209-030 rack

TRICONEX AI3351 Digital 24VDC output module

TRICONEX 7400213-100 System

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: