Description

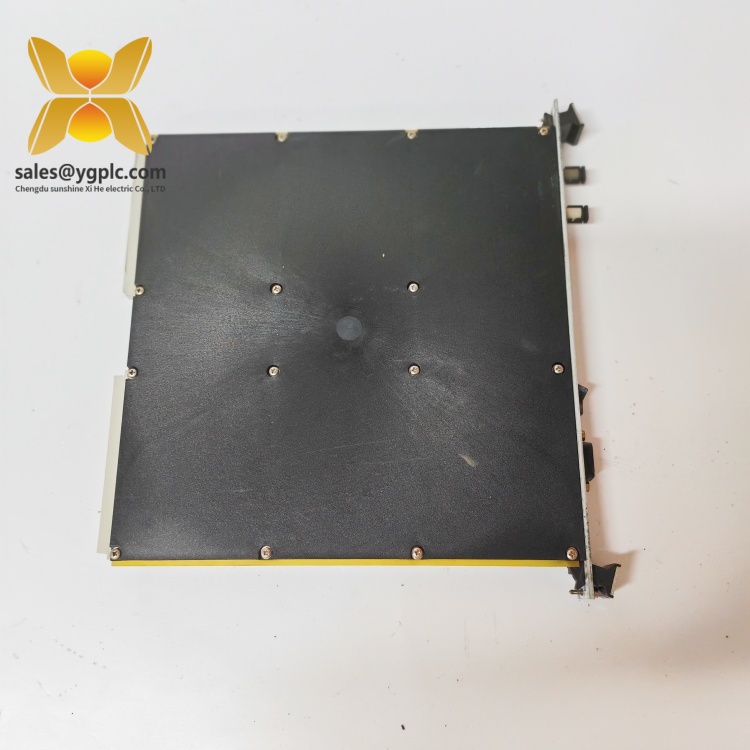

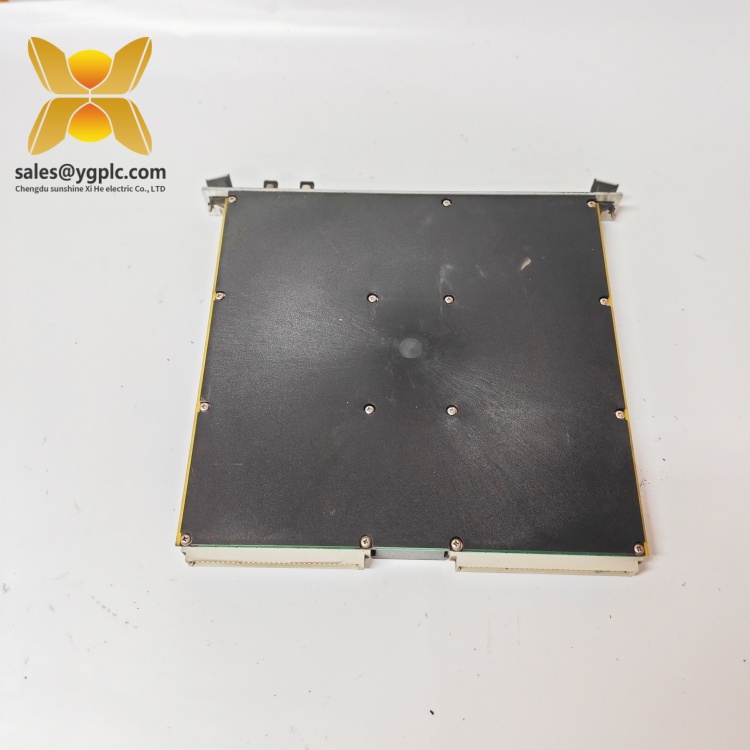

WOODWARD 5501-470 Digital Turbine Controller

Product Overview:WOODWARD 5501-470

The :WOODWARD 5501-470 is a high-precision Digital Turbine Controller designed to optimize the performance and reliability of industrial steam and gas turbines in critical power generation and process control applications. As part of Woodward’s renowned 5500 Series of turbine control solutions, this module serves as a central interface between sensor inputs and actuation systems, delivering real-time control of speed, load, and process parameters. The 5501-470 integrates advanced PID control algorithms and adaptive tuning capabilities, ensuring stable operation across varying load conditions while minimizing mechanical stress on turbine components.

Engineered for scalability, the WOODWARD 5501-470 supports multiple control modes (e.g., speed control, power control, process control) and interfaces with a wide range of field devices, including pressure transducers, LVDTs, and solenoid valves. Its rugged design, compliant with IEC 61131-2 standards, ensures reliable performance in harsh environments with temperatures ranging from -40°C to +85°C. The controller’s modular architecture allows seamless integration into existing turbine control systems, reducing retrofit complexity and enhancing operational efficiency. By combining high-speed processing (32-bit microprocessor) with redundant communication pathways, the 5501-470 ensures uninterrupted control and rapid response to transient events, making it indispensable for industries reliant on continuous power generation and process stability.

In automation ecosystems, the WOODWARD 5501-470 acts as a cornerstone of turbine protection and optimization, bridging the gap between raw sensor data and actionable control commands. Its user-friendly configuration software, Woodward Turbine Control Studio, enables intuitive setup of control loops, alarm thresholds, and diagnostic parameters, reducing commissioning time and enhancing maintainability. Whether deployed in standalone turbines or multi-unit power plants, this controller delivers precise regulation, predictive maintenance insights, and compliance with modern grid codes, positioning it as a strategic asset for industrial operators worldwide.

Technical Specifications:WOODWARD 5501-470

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 5501-470 |

| Manufacturer | Woodward |

| Product Type | Digital Turbine Controller |

| Input Voltage | 24 V DC ±15% |

| Communication Protocols | Modbus RTU, Ethernet/IP, Profibus DP |

| Control Modes | Speed control, load control, process control, automatic synchronizing |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 101.6 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -40°C to +85°C |

| Input Channels | 8 analog inputs (4–20 mA/0–10 V), 16 digital inputs |

| Output Channels | 4 analog outputs (4–20 mA), 8 relay outputs |

| Certifications | CE, UL, API 612, ISO 13709 |

5501-470

Key Features and Advantages:WOODWARD 5501-470

Adaptive Control Algorithms: The WOODWARD 5501-470 employs advanced PID control with auto-tuning capabilities, dynamically adjusting to changing load conditions to maintain turbine speed within ±0.1% of setpoint. This precision minimizes frequency fluctuations in power generation applications and ensures smooth load sharing in parallel turbine setups.

Redundant Architecture: Built with dual-core processing and redundant power supplies, the controller offers fault tolerance for mission-critical operations. In the event of a component failure, seamless switchover to backup systems prevents unplanned shutdowns, enhancing system availability.

Comprehensive Diagnostics: Integrated diagnostic tools provide real-time insights into sensor health, control loop performance, and power supply status. Alarms and fault codes are logged locally and transmitted via communication protocols, enabling proactive maintenance and reducing downtime.

Flexible I/O Configuration: With configurable analog and digital I/O channels, the 5501-470 adapts to diverse turbine setups, supporting both legacy analog sensors and modern digital field devices. This flexibility reduces the need for custom interface modules, lowering hardware costs.

Robust Environmental Performance: The controller’s rugged enclosure and conformal coating protect against dust, moisture, and electromagnetic interference, making it suitable for harsh industrial environments, including offshore platforms and high-vibration machinery rooms.

User-Friendly Software: Woodward’s Turbine Control Studio allows operators to configure control parameters, monitor real-time data, and perform firmware updates via a intuitive graphical interface. This reduces training requirements and streamlines system commissioning.

5501-470

Application Areas:WOODWARD 5501-470

The WOODWARD 5501-470 is widely deployed in industries where precise turbine control is non-negotiable:

- Power Generation: Optimizing speed and load control in steam turbines for thermal power plants, gas turbines for combined-cycle plants, and emergency backup generators. It ensures stable power output and compliance with grid synchronization standards.

- Oil & Gas: Managing turbine-driven compressors and pumps in refineries, pipelines, and offshore platforms. The controller’s fault-tolerant design meets safety-critical requirements for explosion-proof environments.

- Industrial Process Control: Regulating steam turbines in manufacturing facilities for processes such as pulp & paper production, chemical synthesis, and energy-intensive material handling. Its adaptive control features optimize energy efficiency and reduce operational costs.

- Marine Engineering: Controlling marine turbines for propulsion systems and onboard power generation, ensuring reliable performance in high-motion, salt-laden environments.

Specific applications include:

- Automatic Generation Control (AGC): Adjusting turbine output in response to grid demand signals, maintaining frequency stability in interconnected power systems.

- Start-Up and Shutdown Sequencing: Managing safe turbine ramp-up/down processes, including valve positioning, lube oil pressure monitoring, and overspeed protection.

- Load Rejection Handling: Rapidly adjusting fuel supply to prevent turbine overspeed during sudden load loss, protecting equipment from catastrophic failure.

Related Products:WOODWARD 5501-470

- WOODWARD 5501-471: A higher-channel variant with 16 analog inputs, designed for complex turbine systems requiring extensive sensor integration.

- WOODWARD 5501-472: Features built-in Ethernet/IP redundancy for mission-critical applications, ensuring uninterrupted communication with supervisory control systems.

- WOODWARD 5502-100: A compact single-loop controller for smaller turbines or auxiliary systems, offering basic speed and process control at a lower cost.

- WOODWARD 9907-1234: A high-speed actuator driver module that pairs with the 5501-470 for precise valve positioning, reducing control latency.

- WOODWARD 8290-1001: A temperature transmitter module optimized for turbine inlet temperature monitoring, enhancing the 5501-470’s thermal control capabilities.

- WOODWARD 505T: A legacy analog controller replaced by the 5501-470, offering digital upgrades for retrofitting older turbine systems.

- WOODWARD 5504-200: A multi-axis controller for combined-cycle turbines, supporting integration with gas turbine control systems.

5501-470

Installation and Maintenance:WOODWARD 5501-470

Installation Preparation:

Before installing the WOODWARD 5501-470, ensure the control panel is properly grounded and ventilated. Verify compatibility with existing sensors and actuators, using shielded cables for analog signals to minimize noise interference. Mount the controller vertically on a DIN rail, leaving at least 50 mm of clearance for heat dissipation. Connect power and communication cables per the wiring diagram, ensuring polarity and voltage specifications are met. Use Woodward Turbine Control Studio to initialize the controller, configure I/O channels, and upload control logic.

Before installing the WOODWARD 5501-470, ensure the control panel is properly grounded and ventilated. Verify compatibility with existing sensors and actuators, using shielded cables for analog signals to minimize noise interference. Mount the controller vertically on a DIN rail, leaving at least 50 mm of clearance for heat dissipation. Connect power and communication cables per the wiring diagram, ensuring polarity and voltage specifications are met. Use Woodward Turbine Control Studio to initialize the controller, configure I/O channels, and upload control logic.

Maintenance Recommendations:

- Routine Checks: Perform monthly visual inspections for loose connections, damaged cables, or overheating. Use the controller’s built-in diagnostics to verify sensor readings and communication link integrity.

- Annual Calibration: Calibrate analog inputs/outputs using traceable test equipment to ensure measurement accuracy. Document calibration results for compliance audits.

- Firmware Updates: Periodically update the controller’s firmware to access new features and security patches, following Woodward’s official procedures to avoid corruption.

- Spare Parts Management: Store a spare 5501-470 in a controlled environment (temperature: 10–30°C, humidity: 20–60% RH) with anti-static packaging to preserve functionality during storage.

5501-470

Product Warranty:WOODWARD 5501-470

Our company provides a 12-month quality warranty for the WOODWARD 5501-470, covering hardware defects under normal use. In the event of performance issues or functional failures, we offer prompt replacement services. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce components, supporting continuous industrial operations. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, ensuring seamless integration and long-term reliability.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

WOODWARD 5466-318 Digital input module

WOODWARD 5466-425 Safety system module

WOODWARD 5501-381 Network communication card

ABB NAIO-03 Optical fiber interface board

ABB PM633 Acquisition card

ABB REF542PLUS Gas turbine card

ABB DSAI130D AI card

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: