Description

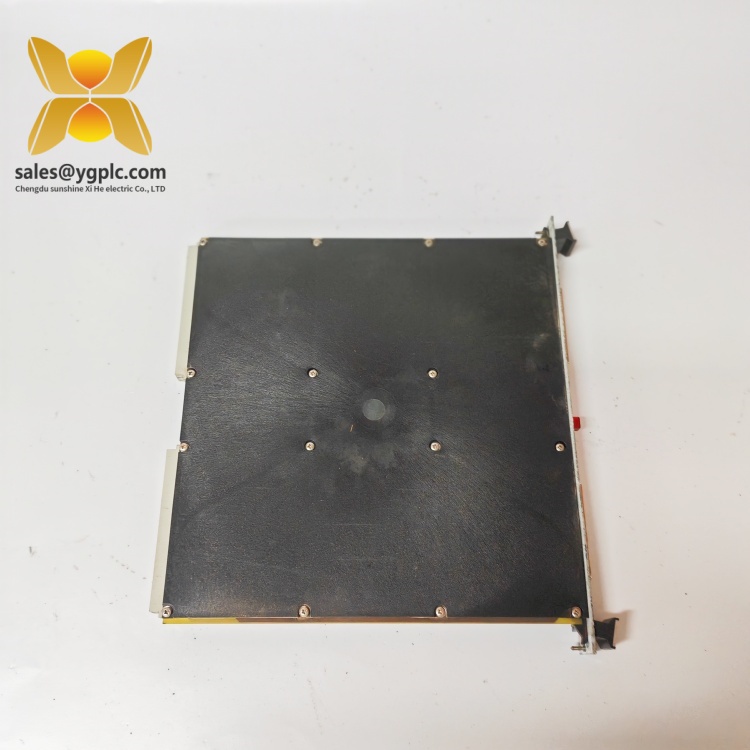

Product Overview :WOODWARD 5466-425

Technical Specifications :WOODWARD 5466-425

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 5466-425 |

| Manufacturer | Woodward |

| Product Type | Turbine Speed Control Module |

| Input Signals | Magnetic pickup (0–20 V AC), proximity probe (DC voltage) |

| Output Signals | 4–20 mA analog, relay contacts, RS-485 (MODBUS RTU) |

| Control Accuracy | ±0.1% of rated speed |

| Power Supply | 10–30 V DC (dual redundant inputs) |

| Physical Dimensions | 178 mm (H) × 127 mm (W) × 76 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | DIN rail or panel-mounted |

| Communication Protocol | MODBUS RTU, proprietary Woodward protocol |

| Certifications | CE, UL, API 612, ISO 10816 |

5466-425

Key Features and Advantages :WOODWARD 5466-425

Ease of Configuration: Using Woodward’s Compuchek software, operators can remotely configure setpoints, calibrate sensors, and perform firmware updates. This intuitive tool streamlines commissioning and allows for on-the-fly adjustments to meet changing operational requirements.

5466-425

Application Areas :WOODWARD 5466-425

- Power Generation: Optimizing speed and load sharing in gas turbine generators for utility-scale power plants, combined heat and power (CHP) systems, and standalone gensets. The module ensures stable frequency regulation during grid synchronization and islanded operation.

- Oil & Gas: Controlling steam turbines in refineries, compressor stations, and offshore platforms to maintain consistent process flow and prevent overspeeding during start-up or shutdown sequences.

- Industrial Machinery: Managing reciprocating engines in manufacturing facilities, water treatment plants, and mining operations, where reliable speed control is essential for process consistency and equipment longevity.

- Marine Applications: Regulating diesel engines in ship propulsion systems and marine power generation, ensuring compliance with maritime safety standards and fuel efficiency requirements.

- Grid Synchronization: Adjusting turbine speed to match grid frequency, minimizing transient stresses on generators and switchgear.

- Load Rejection Control: Rapidly responding to sudden load loss to prevent overspeeding and trigger protective shutdowns if necessary.

- Multi-Engine Paralleling: Coordinating speed and load distribution across multiple turbines in a power plant, optimizing energy output and reducing fuel consumption.

5466-425

Related Products :WOODWARD 5466-425

- WOODWARD 5466-426: A variant with additional analog input channels, suitable for applications requiring integration with multiple process variables (e.g., temperature, pressure).

- WOODWARD 5466-427: Features the same core functionality as the 5466-425 but includes the ability to interface with dual speed sensors for enhanced redundancy in critical systems.

- WOODWARD 5440-1120: A higher-performance turbine control system designed for large-scale gas turbines, offering advanced predictive control and expanded I/O capabilities.

- WOODWARD 8290-1234: A compact governor actuator that pairs with the 5466-425 to convert control signals into mechanical movement, ensuring precise throttle adjustment.

- WOODWARD 9907-1234: A communication gateway module that enables Ethernet connectivity for the 5466-425, facilitating remote monitoring and diagnostics via SCADA systems.

- WOODWARD 505 Digital Governor: A standalone controller for smaller turbines, serving as a cost-effective alternative for applications with less complex control requirements.

- WOODWARD 5464-321: A temperature control module that complements the 5466-425 in multi-variable control systems, managing turbine inlet temperature for improved efficiency.

Installation and Maintenance :WOODWARD 5466-425

Before installing the WOODWARD 5466-425, ensure the control panel is properly grounded and ventilated. Verify compatibility with sensor types (e.g., magnetic pickup voltage range) and use shielded cables to minimize electromagnetic interference. Mount the module on a DIN rail or panel using the provided brackets, leaving at least 25 mm of clearance for heat dissipation. Connect power inputs to a redundant 24 V DC supply and terminate sensor/actuator wires in the designated terminal blocks, following Woodward’s wiring diagrams.

- Routine Checks: Inspect the module monthly for loose connections, corroded terminals, or physical damage. Use a dry cloth to clean dust from the enclosure vents, ensuring adequate airflow.

- Calibration: Perform annual calibration using Compuchek software to verify speed sensor accuracy and control loop responsiveness. Document calibration results for compliance with industry standards.

- Firmware Updates: Periodically update the module’s firmware to access bug fixes and new features, following Woodward’s release notes. Back up existing configurations before updating to prevent data loss.

- Spare Parts Management: Store a spare 5466-425 module in a controlled environment (temperature: 10–30°C, humidity: ≤70%) to facilitate quick replacement in case of failure. Ensure spare modules are periodically powered up to maintain component health.

5466-425

Product Warranty:WOODWARD 5466-425

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

Woodward 8237-1600 Input module

ABB DSDP140B 57160001-ACX Logic controller

ABB SC520 3BSE003816R1 Control panel

ABB CS513 3BSE000435R1 Double output

ABB 3EST125-975 DCC2382A CPU module

PACIFIC 33VM52-000-29 Pulse input (PI) module

ABB 500SCM01 1MRB150004R0001 1MRB200059-C Digital input module

ABB 500TRM02 1MRB150011R0001 Digital 24VDC output module

Elmo G-TUB30-480ERSS0 Digital output module 24VDC

GE UCSC H1 IS420UCSCH1A-B Output module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: