Description

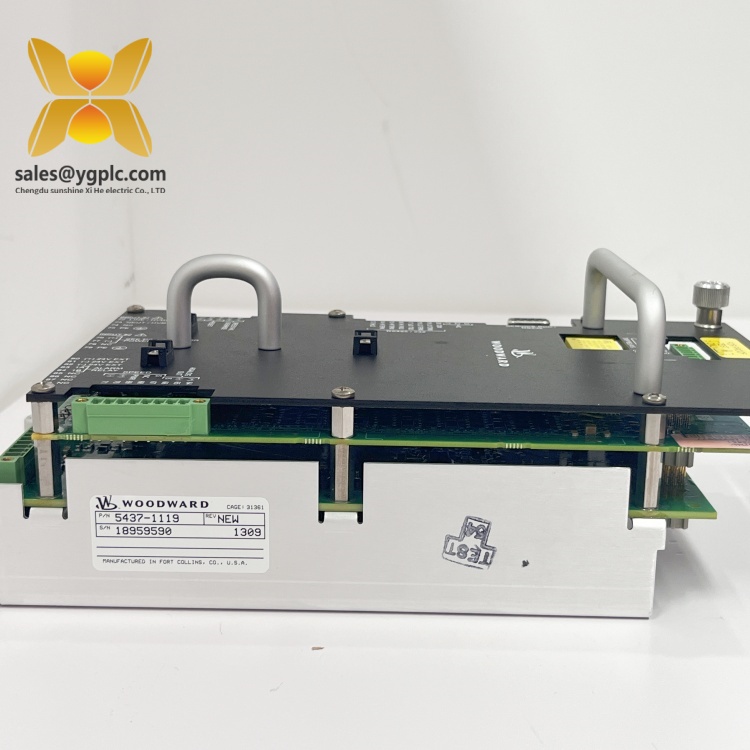

WOODWARD 5437-1119 Product Specification

Product Overview:WOODWARD 5437-1119

The WOODWARD 5437-1119 is a high-reliability safety protection module designed for mission-critical industrial automation systems, particularly in turbine control and power generation applications. As part of WOODWARD’s ProTech-GII series, this module serves as a core component in safety instrumented systems (SIS) and emergency shutdown systems (ESD), providing real-time monitoring and fail-safe control to prevent catastrophic failures. Engineered for seamless integration with WOODWARD’s automation platforms, the WOODWARD 5437-1119 ensures compliance with international safety standards (e.g., IEC 61508) and delivers exceptional performance in harsh industrial environments.

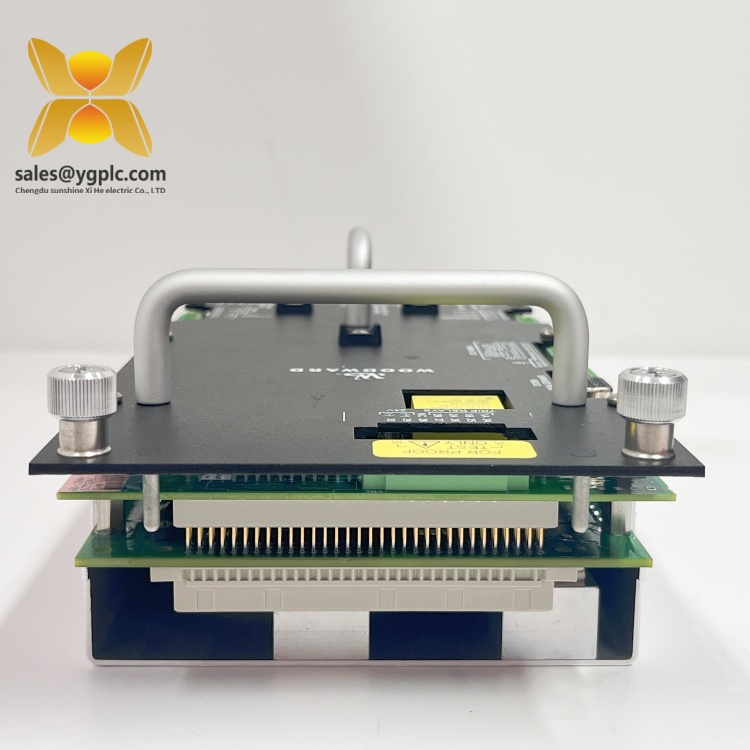

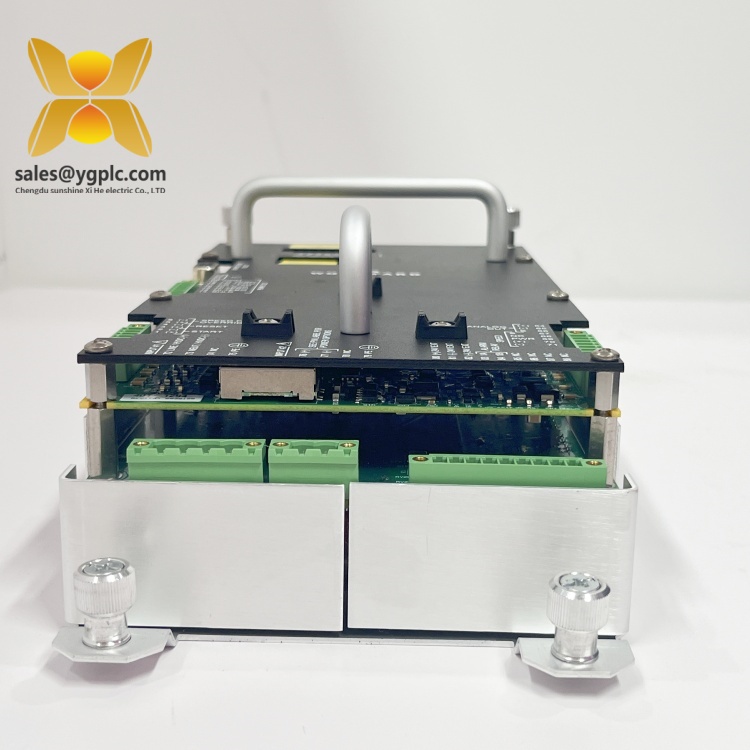

At its core, the WOODWARD 5437-1119 combines advanced diagnostic capabilities with redundant signal processing to monitor critical parameters such as turbine speed, vibration, and temperature. It features 8 analog inputs (4–20 mA) and 4 digital outputs, enabling precise control over actuators and relays in safety-critical loops. The module supports Modbus RTU communication for seamless integration with PLCs, HMIs, and other field devices, while its 24 VDC power supply and wide operating temperature range (-20°C to +60°C) ensure stability in extreme conditions. With 512 KB flash memory and 128 KB RAM, it efficiently stores configuration data and executes complex safety algorithms, enhancing system responsiveness and diagnostic accuracy.

In automation systems, the WOODWARD 5437-1119 acts as a vital link between sensors and control systems, providing fail-safe protection against overspeeding, overheating, and other hazardous events. Its SIL 2-compliant design (safety integrity level pending verification) makes it suitable for applications requiring high levels of safety, such as oil and gas production, power plants, and chemical processing. By integrating with WOODWARD’s ProTech-GII platform, the module empowers engineers to optimize workflow, reduce downtime, and ensure regulatory compliance. Its compact form factor (100 mm × 150 mm × 80 mm) and rugged construction further enhance its appeal in space-constrained or high-vibration environments.

Technical Specifications:WOODWARD 5437-1119

| Parameter Name | Parameter Value |

|---|---|

| Product Model | WOODWARD 5437-1119 |

| Manufacturer | WOODWARD |

| Product Type | Safety Protection Module |

| Signal Channels | 8 analog inputs (4–20 mA), 4 digital outputs |

| Communication Protocol | Modbus RTU |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 100 mm (W) × 150 mm (H) × 80 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5–95% non-condensing |

| Memory | 512 KB flash, 128 KB RAM |

| Installation | DIN rail-mounted |

| Country of Origin | United States |

| Certifications | CE, UL |

WOODWARD 5437-1119

Main Features and Advantages:WOODWARD 5437-1119

Fail-Safe Design: The WOODWARD 5437-1119 incorporates redundant signal processing and self-diagnostic capabilities to ensure reliable operation in safety-critical applications. Its fail-safe outputs automatically trigger shutdown sequences in the event of sensor failure or abnormal,minimizing the risk of equipment damage or personnel injury.

High-Precision Monitoring: With 8 analog input channels supporting 4–20 mA signals, the module provides accurate measurement of process variables such as pressure, temperature, and vibration. This precision enables early detection of anomalies and proactive maintenance, reducing unplanned downtime.

Multi-Protocol Connectivity: The module’s Modbus RTU interface facilitates seamless integration with existing automation infrastructure, allowing real-time data exchange with PLCs, HMIs, and other devices. This interoperability reduces the need for additional communication gateways, simplifying system design and lowering implementation costs.

Extended Environmental Tolerance: Built to withstand extreme temperatures, humidity, and vibration, the WOODWARD 5437-1119 excels in harsh industrial settings. Its conformal-coated PCBs and rugged enclosure protect against dust, moisture, and electromagnetic interference (EMI), ensuring long-term reliability.

Scalable Configuration: As part of WOODWARD’s ProTech-GII series, the WOODWARD 5437-1119 can be easily expanded with compatible modules (e.g., analog/digital I/O cards, communication gateways) to meet evolving system requirements. This scalability makes it suitable for both small-scale installations and large, complex automation projects.

WOODWARD 5437-1119

Application Areas:WOODWARD 5437-1119

The WOODWARD 5437-1119 is widely deployed in industries requiring high-integrity safety systems:

-

Oil and Gas:

- Manages emergency shutdown systems (ESD) in offshore platforms and refineries, ensuring rapid response to process anomalies.

- Monitors turbine speed and vibration in compressors and pumps to prevent overspeeding and mechanical failure.

-

Power Generation:

- Controls steam and gas turbines by processing analog signals from speed sensors and executing relay-based shutdown commands.

- Supports predictive maintenance by analyzing vibration data from rotating machinery, enhancing operational efficiency.

-

Chemical Processing:

- Monitors critical parameters (e.g., temperature, pressure) in reactor systems, triggering safety interlocks to prevent overheating or chemical spills.

- Integrates with distributed control systems (DCS) for centralized monitoring and control of safety-critical processes.

-

Water/Wastewater Treatment:

- Controls pump stations and chemical dosing systems via analog input signals and fail-safe digital outputs.

- Ensures compliance with environmental regulations by monitoring effluent quality and activating alarms or shutdowns when thresholds are exceeded.

WOODWARD 5437-1119

Related Products:WOODWARD 5437-1119

- WOODWARD 8237-1246: A overspeed detection module designed for turbine control systems, often paired with the WOODWARD 5437-1119 to provide comprehensive safety coverage.

- WOODWARD 9853-610: A high-precision analog input module that enhances the WOODWARD 5437-1119’s signal conditioning capabilities for critical process measurements.

- WOODWARD 8440-1706-A-SPM-D11: A governor module that works in tandem with the WOODWARD 5437-1119 to optimize turbine speed control and load sharing.

- WOODWARD 8256-016: An electric governor module supporting embedded iFix software, ideal for retrofitting legacy systems with advanced control functionality.

- WOODWARD BC810 CEX Bus Unit: A bus expansion unit that enhances system scalability by segmenting the CEX bus into independent segments, compatible with the WOODWARD 5437-1119.

Installation and Maintenance:WOODWARD 5437-1119

Pre-installation Preparation:

Before installing the WOODWARD 5437-1119, ensure the following:

Before installing the WOODWARD 5437-1119, ensure the following:

- Verify the power supply meets the module’s requirements (24 VDC ±10%) and that the DIN rail is properly grounded.

- Use WOODWARD’s configuration software to set analog input ranges, digital output states, and Modbus RTU parameters.

- Secure the module in a well-ventilated enclosure to prevent overheating, particularly in high-density installations.

Maintenance Recommendations:

- Routine Checks: Inspect front-panel LEDs monthly to confirm normal operation (e.g., green “Power” and “Health” indicators). Replace faulty modules immediately to prevent cascading failures.

- Signal Calibration: Perform annual calibration of analog inputs using certified test equipment to maintain accuracy. Digital outputs should be tested for contact resistance and switching time.

- Firmware Updates: Periodically update the module’s firmware via WOODWARD’s dedicated software to access new features and security patches.

- Environmental Monitoring: Monitor ambient temperature and humidity levels, as extreme conditions can degrade performance. Clean dust from vents quarterly to prevent overheating.

WOODWARD 5437-1119

Product Warranty:WOODWARD 5437-1119

Our company provides a one-year quality warranty for the WOODWARD 5437-1119, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models like the WOODWARD 5437-1119, our global inventory of legacy industrial control parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services through our network of certified technicians, ensuring your critical systems remain operational long after the warranty expires.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from WOODWARD’s official specifications and industry applications. For detailed operational guidelines, refer to the WOODWARD 5437-1119 user manual or contact our technical support team for personalized assistance.

WOODWARD 8200-1302 Digital output module 24VDC

WOODWARD 8273-140 Output module

Woodward 8237-1600 High density main box

WOODWARD 5453-277 Remote extender module

WOODWARD 5453-279 Input pulse module

GE IS220PAICH1B Power strip

GE IS220PDIAH1A Network communication

GE CK11CE300 Safety system

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: