Description

VIBRO-METER VM600 RPS6U 200-582-600-013 Product Specification

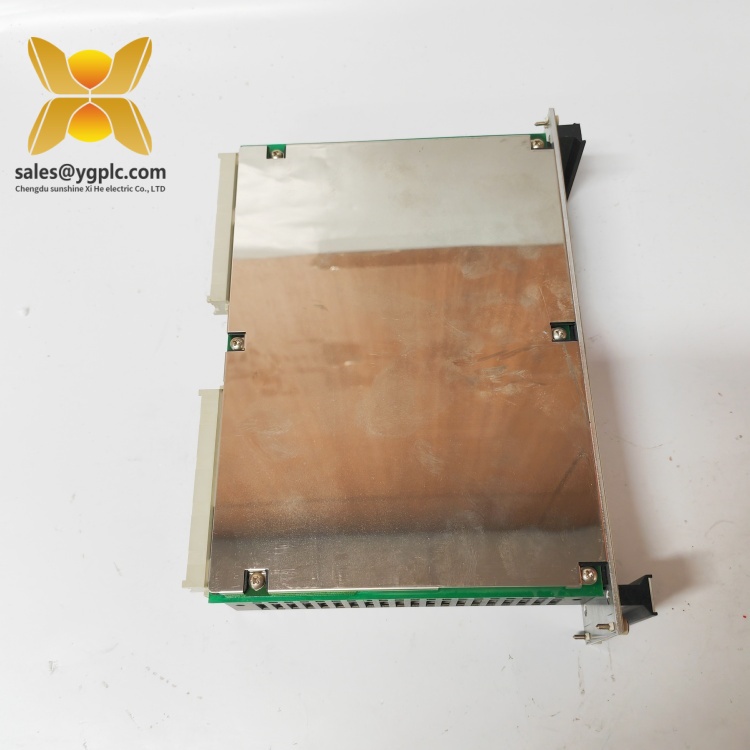

Product Overview:VIBRO-METER VM600 RPS6U 200-582-600-013

The VIBRO-METER VM600 RPS6U 200-582-600-013 is a high-precision vibration monitoring module designed for critical rotating machinery in industrial automation systems. As part of Emerson’s VIBRO-METER VM600 series, this module specializes in real-time monitoring of vibration parameters, such as velocity, acceleration, and displacement, to ensure the reliable operation of turbines, compressors, and pumps. Engineered for safety-critical environments, the VM600 RPS6U 200-582-600-013 integrates advanced signal processing and diagnostic capabilities, making it a cornerstone in predictive maintenance strategies across industries like power generation, oil and gas, and manufacturing.

Featuring a modular design, the VM600 RPS6U 200-582-600-013 supports up to four independent input channels, each compatible with proximity probes, velocity transducers, or accelerometers. It processes raw vibration data into actionable insights, including overall vibration levels, bearing condition indicators, and shaft displacement measurements. The module communicates via analog outputs (4–20 mA) and digital interfaces (RS-485 with Modbus RTU), enabling seamless integration with distributed control systems (DCS) or programmable logic controllers (PLCs). Its compact form factor (177.8 mm height × 101.6 mm width × 254 mm depth) and DIN rail mounting facilitate easy installation in both new and retrofitted systems, while its rugged construction ensures stability in harsh environments with temperatures ranging from -40°C to +70°C.

In automation systems, the VM600 RPS6U 200-582-600-013 acts as a vital layer of protection against unexpected machinery failures. By continuously analyzing vibration patterns, it identifies early signs of wear, misalignment, or imbalance, allowing maintenance teams to schedule interventions proactively and minimize downtime. The module’s dual-channel redundancy support enhances system reliability, while its compliance with industry standards (e.g., API 670, ISO 10816) ensures compatibility with global safety and operational requirements.

Technical Specifications:VIBRO-METER VM600 RPS6U 200-582-600-013

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VIBRO-METER VM600 RPS6U 200-582-600-013 |

| Manufacturer | VIBRO-METER (Emerson) |

| Product Type | Vibration Monitoring Module |

| Input Channels | 4 channels (proximity probes, velocity transducers, accelerometers) |

| Measurement Parameters | Vibration velocity (mm/s), acceleration (g), shaft displacement (μm), bearing temperature |

| Communication Interfaces | Analog: 4–20 mA (8 outputs); Digital: RS-485 (Modbus RTU) |

| Power Supply | 100–240 VAC, 50/60 Hz |

| Physical Dimensions | 177.8 mm (H) × 101.6 mm (W) × 254 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5%–95% non-condensing |

| Compliance | API 670, ISO 10816, CE, UL |

VM600 RPS6U 200-582-600-013

Main Features and Advantages:VIBRO-METER VM600 RPS6U 200-582-600-013

Comprehensive Vibration Analysis: The VM600 RPS6U 200-582-600-013 delivers multi-parameter monitoring, capturing both dynamic vibration signals and static operational data. Its FFT-based spectrum analysis identifies frequency-domain anomalies, such as resonance or harmonic distortions, while time-domain trends track changes in overall vibration severity. This dual-analysis approach enables precise fault diagnosis, distinguishing between issues like bearing degradation and mechanical looseness.

Redundant and Reliable Design: With support for dual-channel redundancy, the module ensures continuous operation even if one channel fails. This feature is critical in uninterruptible processes, such as offshore oil platforms or power plant turbines, where system downtime could lead to significant financial losses or safety hazards. The module’s rugged enclosure and wide temperature range further enhance its reliability in extreme industrial environments.

User-Friendly Integration: The VM600 RPS6U 200-582-600-013 simplifies integration with existing control systems through its standard analog and digital interfaces. Engineers can configure the module using Emerson’s ProVu software, which provides a intuitive dashboard for setting alarm thresholds, calibrating sensors, and generating trend reports. This reduces commissioning time and minimizes the need for specialized training.

Predictive Maintenance Enabler: By providing real-time access to vibration data, the module empowers industries to shift from reactive to predictive maintenance strategies. Early detection of machinery issues allows for targeted repairs, reducing reliance on emergency shutdowns and extending equipment lifespan. The module’s historical data logging capability also supports long-term trend analysis, helping identify systemic issues across fleets of machinery.

VM600 RPS6U 200-582-600-013

Application Areas:VIBRO-METER VM600 RPS6U 200-582-600-013

The VM600 RPS6U 200-582-600-013 is ideally suited for industries where the reliability of rotating equipment is non-negotiable:

-

Power Generation:

- Monitors steam and gas turbines, generators, and pumps in thermal and nuclear power plants, ensuring consistent energy production and compliance with environmental regulations.

- Detects early signs of blade erosion or bearing wear, preventing catastrophic failures that could disrupt grid stability.

-

Oil and Gas:

- Installed in offshore platforms, refineries, and pipelines to monitor compressors, motors, and centrifugal pumps.

- Supports safety-critical applications by integrating with emergency shutdown (ESD) systems, triggering alarms or shutdowns when vibration thresholds are exceeded.

-

Manufacturing and Process Industries:

- Used in automotive and pharmaceutical production lines to monitor high-speed rotating machinery, such as spindles, conveyors, and mixers.

- Ensures quality control by identifying vibration-related issues that could affect product consistency, such as misalignment in packaging equipment.

-

Water and Wastewater Treatment:

- Monitors pumps and blowers in treatment plants, ensuring continuous operation and preventing disruptions to water supply or sewage processing.

- Reduces maintenance costs by predicting equipment failures before they lead to service interruptions.

VM600 RPS6U 200-582-600-013

Related Products:VIBRO-METER VM600 RPS6U 200-582-600-013

- VIBRO-METER VM600 RPS6U 200-582-600-014: An upgraded version with enhanced data storage and Ethernet connectivity, suitable for large-scale monitoring networks.

- VIBRO-METER PR6423/003-030: A proximity probe designed for shaft vibration and displacement measurement, commonly paired with the VM600 RPS6U 200-582-600-013 for complete vibration monitoring systems.

- EMERSON CSI 6500: A comprehensive machinery health monitoring system that integrates with the VM600 RPS6U 200-582-600-013 to provide advanced analytics and asset management capabilities.

- VIBRO-METER VM600 TPS6U: A temperature monitoring module within the VM600 series, often used alongside the RPS6U to create multi-parameter monitoring solutions.

- VIBRO-METER VM600 BCM6U: A bearing condition monitoring module that complements the RPS6U by analyzing high-frequency vibration signals to detect early bearing defects.

Installation and Maintenance:VIBRO-METER VM600 RPS6U 200-582-600-013

Pre-installation Preparation:

Before installing the VM600 RPS6U 200-582-600-013, ensure the following:

Before installing the VM600 RPS6U 200-582-600-013, ensure the following:

- Verify the power supply voltage (100–240 VAC) and ensure proper grounding to minimize electromagnetic interference.

- Mount the module on a DIN rail in a controlled environment, away from direct moisture or extreme temperature fluctuations.

- Connect compatible sensors (e.g., proximity probes) to the input channels, following the wiring diagrams provided in the user manual.

Maintenance Recommendations:

- Regularly inspect the module’s LED indicators to confirm operational status (e.g., power, communication, alarm conditions).

- Calibrate sensors annually using certified calibration tools to ensure measurement accuracy.

- Update the module’s firmware periodically via ProVu software to access the latest features and bug fixes.

- Review trend data monthly to identify gradual changes in vibration patterns, which may indicate developing issues.

VM600 RPS6U 200-582-600-013

Product Warranty:VIBRO-METER VM600 RPS6U 200-582-600-013

Our company provides a one-year quality warranty for the VIBRO-METER VM600 RPS6U 200-582-600-013, covering hardware defects unrelated to misuse or environmental damage. During the warranty period, we will replace any faulty components at no additional cost. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce spare parts, minimizing downtime and supporting the sustained operation of your industrial systems. Trust our 17 years of expertise in industrial control to deliver reliable solutions for your vibration monitoring needs.

Contact Information:

WhatsApp: +86 18859254943

Email: sales@ygplc.com

WhatsApp: +86 18859254943

Email: sales@ygplc.com

Note: This description is based on extensive research across technical datasheets and industry applications. For detailed operational guidelines, refer to the official VIBRO-METER manual or contact our technical support team.

VIBRO-METER VM600 IOC4T 200-560-000-111 200-560-101-017 rack

VIBRO-METER VM600 IOC16T 200-565-000-013 200-565-101-013 Remote module

GE IS210AEBIH1BED Distributed control

GE IS210MACCH1AGG Terminal panel

ABB PPD117A3011 3BHE030410R3011 PDP panel

Foxboro H92 H92A049E0700 programmable

Yokogawa V1702 Logic controller

ABB 3BHE023784R2530 PPD113B01-25-111000 Control panel

ABB 3BHE032025R0101 PCD235A101 Double output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: