Description

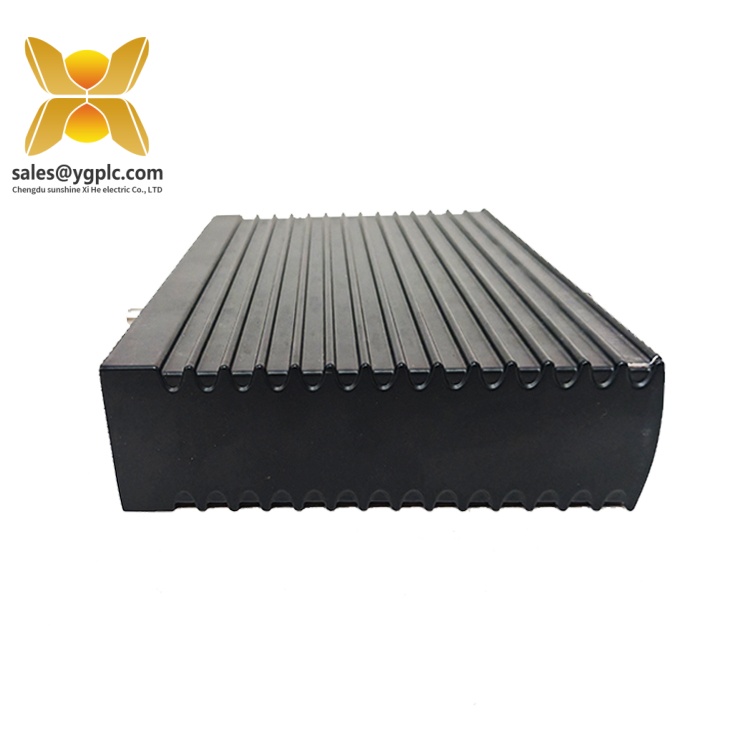

Product Overview

The TRICONEX EPI3382 is a high – performance control module developed by TRICONEX, a renowned name in the industrial automation and safety systems domain. This module is designed to be a cornerstone in ensuring the seamless operation and control of various industrial processes. It is an integral part of TRICONEX’s comprehensive suite of products, which are known for their reliability, precision, and advanced technological features.Whatsapp:+86 18859254943.

TRICONEX EPI3382 offers a wide array of control and monitoring functions. It can effectively manage and regulate complex industrial operations, making it suitable for use in critical applications where system stability and accurate control are non – negotiable. For instance, in safety – instrumented systems (SIS), it plays a pivotal role in ensuring that safety – related processes are executed flawlessly. By constantly monitoring input signals from various sensors and devices, it can make real – time decisions and output appropriate control signals to maintain the safety and efficiency of the overall system.

This module is built with a focus on high – reliability. It incorporates advanced technologies and robust design principles to withstand the harsh environmental conditions often encountered in industrial settings. Whether it’s extreme temperatures, high humidity, or electrical interference, the TRICONEX EPI3382 is engineered to operate consistently and without interruption. E-mail :sales@ygplc.com.This makes it an ideal choice for industries such as oil and gas, petrochemicals, power generation, and manufacturing, where continuous operation is crucial for both productivity and safety.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | EPI3382 |

| Manufacturer | TRICONEX |

| Product Type | Control Module |

| Processor Type | Multi – core (designed for high – speed processing and efficient multitasking) |

| Input/Output Interfaces | Multiple digital and analog I/O interfaces to support connection with a wide range of sensors and actuators |

| Communication Protocols | Supports industry – standard protocols like Modbus, Ethernet/IP, etc., enabling seamless integration with other components in the control system |

| Power Supply Requirements | Operates on a stable DC power supply (e.g., 24 VDC, check the exact value in the product manual) |

| Operating Temperature Range | Designed to function within a wide temperature range, typically from – 40 °C to + 70 °C, suitable for harsh industrial environments |

| Humidity Tolerance | Can withstand humidity levels from 0% – 95% non – condensing, ensuring reliable operation in humid conditions |

| Physical Dimensions | Compact design with dimensions [specify the length, width, and height in millimeters if available], allowing for easy installation in various control cabinets |

| Redundancy Features | Equipped with advanced redundancy mechanisms to enhance system reliability in case of component failures |

| Memory Capacity | Sufficient memory (both RAM and flash memory) for storing program logic, data, and configuration settings |

EPI3382

Main Features and Advantages

High – Performance Processing

The TRICONEX EPI3382 is powered by a multi – core processor, which enables it to handle complex control algorithms and process large amounts of data at high speeds. This high – performance processing capability ensures that the module can respond rapidly to changes in the industrial process, making it possible to maintain tight control over critical parameters. For example, in a chemical reactor, where precise temperature and pressure control are essential for the reaction to proceed correctly, the EPI3382 can quickly analyze sensor data and adjust control outputs to keep the process within the desired operating range.

Robust Design for Harsh Environments

With its rugged construction, the TRICONEX EPI3382 is well – equipped to operate in harsh industrial environments. It is designed to withstand mechanical vibrations, electrical noise, and extreme temperatures. This makes it suitable for use in applications such as oil rigs, where equipment is exposed to harsh weather conditions and constant vibrations, or in petrochemical plants, where the presence of corrosive substances and high – temperature processes can pose challenges to the operation of electronic components.E-mail :sales@ygplc.com.

Advanced Redundancy and Fault – Tolerance

Redundancy is a key feature of the TRICONEX EPI3382. It incorporates multiple levels of redundancy, including redundant power supplies and communication channels. In the event of a component failure, the redundant systems can take over seamlessly, ensuring that the control process continues without interruption. This high level of fault – tolerance minimizes the risk of system downtime, which is crucial in industries where any interruption in production can lead to significant financial losses and safety hazards.

EPI3382

Flexible Configuration Options

The module offers extensive flexibility in configuration. Users can customize its settings to meet the specific requirements of their industrial processes. This includes the ability to configure input and output channels, communication protocols, and control algorithms. For example, in a power generation plant, the EPI3382 can be configured to interface with different types of sensors and actuators used in the turbine control system, as well as to communicate with other components in the plant’s distributed control system (DCS) using the most suitable communication protocol.

Application Areas

Oil and Gas Industry

In the oil and gas sector, the TRICONEX EPI3382 is widely used for controlling and monitoring critical processes. It can be employed in oil refineries to regulate the flow of crude oil, control the temperature and pressure in distillation columns, and manage the operation of pumps and valves. In gas processing plants, it plays a crucial role in ensuring the safe and efficient processing of natural gas, including tasks such as gas compression, dehydration, and sulfur removal. By providing accurate control and reliable monitoring, the EPI3382 helps to optimize production, prevent equipment failures, and enhance the overall safety of the oil and gas operations.Whatsapp:+86 18859254943.

Power Generation

Power generation facilities, whether they are based on fossil fuels, nuclear energy, or renewable sources such as wind and solar, rely on the TRICONEX EPI3382 for effective control and monitoring. In thermal power plants, it can control the combustion process in boilers, adjust the speed of turbines, and manage the distribution of electrical power. In wind farms, the module can be used to control the pitch and yaw of wind turbines, ensuring optimal energy capture and safe operation. In nuclear power plants, its high – reliability and safety – critical features make it suitable for use in reactor control systems, where precise control is essential for the safe operation of the nuclear reactor.

Manufacturing

The manufacturing industry also benefits greatly from the use of the TRICONEX EPI3382. In automotive manufacturing plants, it can be used to control the operation of robotic arms, conveyor belts, and other automated equipment on the production line. This ensures the precise and efficient assembly of vehicles, improving product quality and production speed. In food and beverage manufacturing, the module can control the filling and packaging processes, ensuring accurate product dosing and proper packaging integrity. Its ability to integrate with other manufacturing systems and provide real – time data for process optimization makes it an invaluable asset in modern manufacturing facilities.

EPI3382

Related Products

- TRICONEX AI3351: An analog input module. It can be used in conjunction with the TRICONEX EPI3382 to provide a complete solution for industrial control systems. The AI3351 is responsible for acquiring analog signals from various sensors, such as temperature and pressure sensors, and sending this data to the EPI3382 for processing and control.

- TRICONEX DO3401: A digital output module. Works in tandem with the EPI3382 to execute control commands. Once the EPI3382 has processed the input data and determined the appropriate control actions, it can send digital signals to the DO3401, which then outputs these signals to drive digital – controlled actuators, like relays and solenoid valves.

- TRICONEX 3503E: A digital input module. It complements the TRICONEX EPI3382 by providing digital input capabilities. The 3503E can receive digital signals from switches, sensors, and other digital devices, and feed this information to the EPI3382, enabling the module to make control decisions based on the status of these digital inputs.

- TRICONEX 4329: A communication module. Facilitates communication between the TRICONEX EPI3382 and other components in the control system. It supports various communication protocols, allowing the EPI3382 to exchange data with other modules, controllers, and even remote monitoring stations, enhancing the overall connectivity and functionality of the industrial control network.

- TRICONEX 9668 – 110: A network – related component. It can be used in the same system as the TRICONEX EPI3382 to enhance network capabilities, such as providing Ethernet connectivity. This can be crucial for enabling the EPI3382 to communicate with other devices over an Ethernet network, facilitating data sharing and remote control in industrial automation setups.

Installation and Maintenance

Installation Preparations: Before installing the TRICONEX EPI3382, ensure that the power supply to the entire control system is turned off to prevent electrical accidents. Check the compatibility of the module with the existing control system components, including power supplies, communication interfaces, and other connected modules. Verify that the physical mounting location meets the environmental requirements in terms of temperature, humidity, and vibration. Prepare the necessary cables and connectors, making sure they are of the correct type and in good condition. Also, have the appropriate tools on hand for the installation process, such as screwdrivers and wire strippers.

EPI3382

Maintenance Recommendations: Regularly inspect the TRICONEX EPI3382 for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the module’s performance by checking for any abnormal behavior or error messages. Clean the module periodically to remove dust and debris, as these can affect its performance over time. Check the power supply voltage regularly to ensure it remains within the specified range. If any issues are detected, refer to the product manual for detailed troubleshooting steps. In case of complex problems, contact our experienced technical support team, who can provide expert guidance and assistance to ensure the continued reliable operation of the EPI3382 module.

Product Assurance

Our company, a leading figure in the industrial control industry since 2007, offers a comprehensive product assurance program for the TRICONEX EPI3382. We provide a one – year quality warranty that covers all hardware failures not caused by human error. E-mail :sales@ygplc.com.During this period, if the EPI3382 experiences any performance anomalies or functional failures, we will promptly provide replacement services. Our vast experience and extensive global supply chain network enable us to quickly respond to customer needs, especially for discontinued models or in cases of urgent requirements. We understand the critical role that the TRICONEX EPI3382 plays in industrial systems, and our commitment to quality and customer satisfaction ensures that you can rely on our services to keep your industrial operations running smoothly and efficiently.

TRICONEX DI3361 driver

TRICONEX DO2401 7400209-030 servo

TRICONEX DO3401 Eddy current sensor

TRICONEX D28799-005 monitor

TRICONEX AI2351 7400210-010 programmable

TRICONEX AO3482 Logic controller

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: