Description

Product Overview

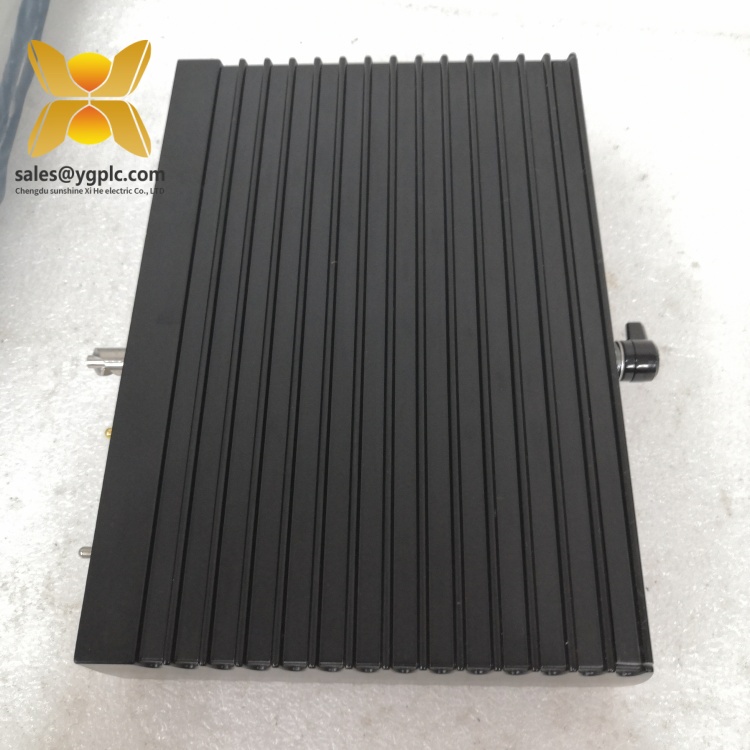

The TRICONEX DO3401 is a high-reliability digital output module developed by TRICONEX, a pioneer in safety instrumented systems (SIS) and critical industrial control solutions. As a key component in automated control architectures, the TRICONEX DO3401 is designed to convert digital control signals from central processors into actionable physical outputs, such as activating valves, triggering alarms, or initiating emergency shutdowns. This conversion is essential for translating system decisions into real-world actions, making the TRICONEX DO3401 a vital link between monitoring systems and field equipment in industrial processes.

The TRICONEX DO3401 is part of TRICONEX’s robust module lineup, engineered to meet the stringent demands of high-risk environments. It holds certification under IEC 61508 for SIL 3 applications, the highest safety integrity level, ensuring it can be trusted in scenarios where failure could lead to catastrophic consequences, including loss of life or major environmental damage. Its seamless integration with TRICONEX’s Tricon and Tricon CX platforms allows for easy incorporation into both new systems and existing setups, making the TRICONEX DO3401 a versatile choice for industries ranging from energy to chemicals. Whether deployed in refineries, power plants, or manufacturing facilities, this module delivers consistent performance, underscoring its role as a reliable solution for executing critical control actions.

Technical Specifications

| Product models | Digital Output Module |

|---|---|

| Manufacturer | TRICONEX |

| Product type | Digital Output Module |

| Number of channels | 8 channels |

| Output type | Relay outputs (Form C, normally open/normally closed) |

| Output voltage rating | 24V DC / 125V AC / 250V AC |

| Isolation | Galvanic isolation (channel-to-channel and channel-to-backplane) |

| Communication interface | Tricon bus protocol |

| Physical dimensions | 102 mm (length) x 156 mm (width) x 29 mm (height) |

| Weight | 260 grams (approximate) |

| Operating temperature range | -40°C to 70°C |

| Storage temperature range | -55°C to 85°C |

| Humidity tolerance | 5% to 95% RH, non-condensing |

| Origin | United States |

| Maximum switching current | 2A per channel |

DO3401

Related products

- TRICONEX DO3402: A digital output module with 16 channels, offering double the output capacity of the TRICONEX DO3401, suitable for systems requiring more simultaneous control actions.

- TRICONEX DI3301: A digital input module that works in tandem with the TRICONEX DO3401, providing the input signals that trigger the output actions, such as detecting sensor states to activate valves.

- TRICONEX AI3351: An analog input module that complements the TRICONEX DO3401 by supplying continuous process data (e.g., pressure or temperature readings) that inform when output actions are needed.

- TRICONEX AO3351: An analog output module, used alongside the TRICONEX DO3401 in systems requiring variable outputs (e.g., modulating valve positions) in addition to discrete on/off actions.

- TRICONEX T8401: The central processor module of TRICONEX systems, which sends control commands to the TRICONEX DO3401 based on logic processing of input data.

- TRICONEX PS3301: A redundant power supply module that ensures stable power delivery to the TRICONEX DO3401 and other system components, preventing output failures due to power interruptions.

- TRICONEX DO3301: A legacy digital output module, predecessor to the TRICONEX DO3401, with similar functionality but lower channel density, suitable for smaller-scale applications.

- TRICONEX IC3600SOSH: A surge protection module that can be paired with the TRICONEX DO3401 to shield it from voltage spikes in harsh electrical environments, extending its operational life.

Main features and advantages

The TRICONEX DO3401 stands out for its combination of safety-certified performance and robust operational reliability, making it indispensable in critical control systems. A primary advantage is its SIL 3 certification under IEC 61508, which validates its ability to maintain functionality even when exposed to potential faults. This certification is particularly critical in industries such as oil and gas or chemical processing, where the failure of an output module could lead to uncontrolled process conditions, endangering workers and equipment.

The TRICONEX DO3401 features 8 relay-based output channels, each designed to handle a range of voltages (24V DC to 250V AC) and a maximum current of 2A. This versatility allows it to interface with a wide variety of field devices, from small solenoid valves to large motor starters, eliminating the need for additional signal converters and simplifying system design. Each channel is equipped with galvanic isolation, which prevents electrical interference between channels and protects the module from ground loops or voltage surges—common issues in industrial environments that can corrupt signals or damage components. This isolation ensures that a fault in one channel does not affect others, enhancing overall system resilience.

Advanced diagnostic capabilities are another key strength of the TRICONEX DO3401. The module continuously performs self-checks, monitoring for faults such as relay sticking or open circuits, and reports these issues in real time to the system controller. This allows operators to address problems proactively, reducing the risk of unplanned downtime and ensuring that critical outputs remain responsive when needed most. Additionally, the TRICONEX DO3401 is fully compatible with TRICONEX’s Tricon and Tricon CX platforms, enabling seamless integration into existing systems without extensive reconfiguration. This compatibility reduces installation time and costs, making it an efficient choice for both new projects and system upgrades.

Ruggedness is also a defining feature of the TRICONEX DO3401. It operates reliably in extreme temperatures (-40°C to 70°C) and high humidity (5% to 95% RH), ensuring performance in harsh environments such as offshore platforms or desert refineries. Its durable construction resists vibration and mechanical shock, further enhancing its suitability for industrial settings where equipment is subject to constant movement or rough handling.

DO3401

Installation and maintenance

Pre-installation preparations: Before installing the TRICONEX DO3401, verify that the target Tricon chassis is compatible with the module and ensure the system is powered off to prevent electrical damage. Inspect the module for physical defects, such as bent pins or cracked casings, which could impair its functionality. Check that field wiring matches the module’s voltage and current specifications, and ensure all connections are properly insulated to avoid short circuits. Clean the chassis mounting slots to remove dust or debris, as foreign particles can cause poor electrical contact or overheating once the TRICONEX DO3401 is installed.

Maintenance suggestions: Regular maintenance of the TRICONEX DO3401 should include visual inspections of the module and its wiring to check for loose connections, corrosion, or signs of overheating—especially in humid or corrosive environments. Use the system’s diagnostic software to run periodic channel tests, activating each output to confirm it responds correctly and returns to its default state when deactivated. Avoid exposing the TRICONEX DO3401 to excessive mechanical stress or vibration, as these can damage internal relays. If a fault is detected (e.g., a stuck relay), refer to the system’s error logs to identify the affected channel, and replace the module if necessary, following proper shutdown procedures to prevent electrical surges to connected equipment.

Application fields

The TRICONEX DO3401 is widely deployed in industries where reliable execution of control actions is critical to safety and process efficiency. In the oil and gas sector, it plays a key role in offshore platforms and onshore refineries, controlling emergency shutdown valves (ESVs) and blowdown systems. When sensors detect dangerous pressure levels or gas leaks, the TRICONEX DO3401 receives signals from the SIS processor and activates these valves, isolating the affected section of the process to prevent explosions or spills.

In chemical processing plants, the TRICONEX DO3401 is used to control reactor feed valves, emergency cooling systems, and alarm sirens. These applications require precise timing—delays in activating a valve could allow a chemical reaction to run out of control, leading to toxic releases or equipment damage. The module’s fast response time and reliable relay operation ensure that these actions are executed without hesitation, maintaining process stability.

Power generation facilities, including nuclear, coal, and natural gas plants, rely on the TRICONEX DO3401 to control turbine trip mechanisms, boiler feedwater valves, and fire suppression systems. In these environments, the module’s ability to operate in high temperatures and withstand vibration is critical, as equipment is often located near hot surfaces or rotating machinery. By activating safety systems when parameters like turbine speed exceed safe limits, the TRICONEX DO3401 helps prevent catastrophic failures that could disrupt power supply.

Pharmaceutical and food processing industries also utilize the TRICONEX DO3401 to control sanitization systems, material transfer valves, and batch shutdown mechanisms. In these sectors, compliance with strict regulatory standards (e.g., FDA guidelines) requires consistent and traceable control actions, which the module’s diagnostic capabilities support by logging output activations for audit purposes. Across all these fields, the TRICONEX DO3401 ensures that critical control commands are translated into effective physical actions, safeguarding operations and personnel.

DO3401

Product guarantee

Our company offers a one-year quality warranty service for the TRICONEX DO3401, covering hardware malfunctions not caused by human factors. During the warranty period, if the TRICONEX DO3401 shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. Our technical team is available to assist with installation guidance and troubleshooting, ensuring that customers can optimize the performance of the TRICONEX DO3401 throughout its operational life. Whether for new system integrations or legacy upgrades, we are committed to delivering timely support to meet the diverse needs of industrial automation users.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: