Description

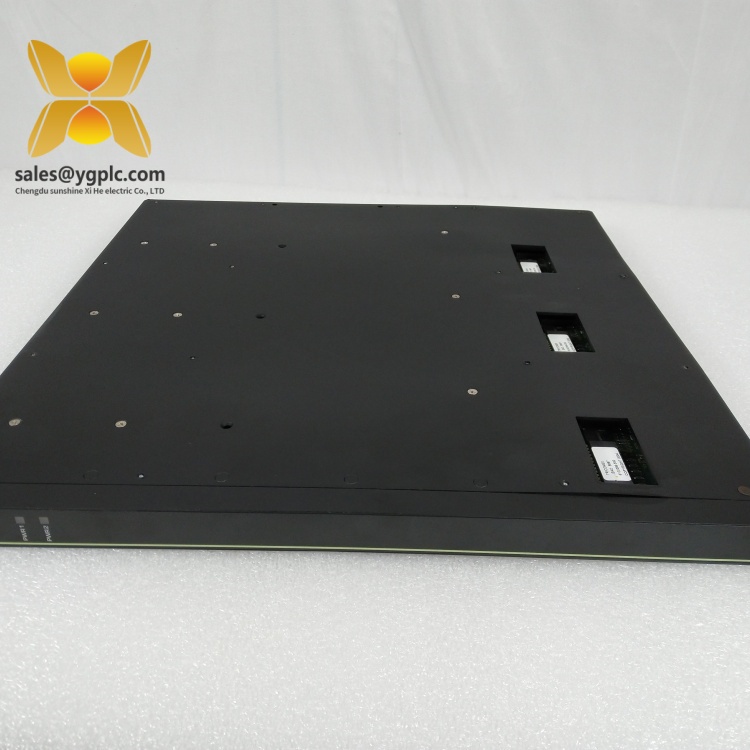

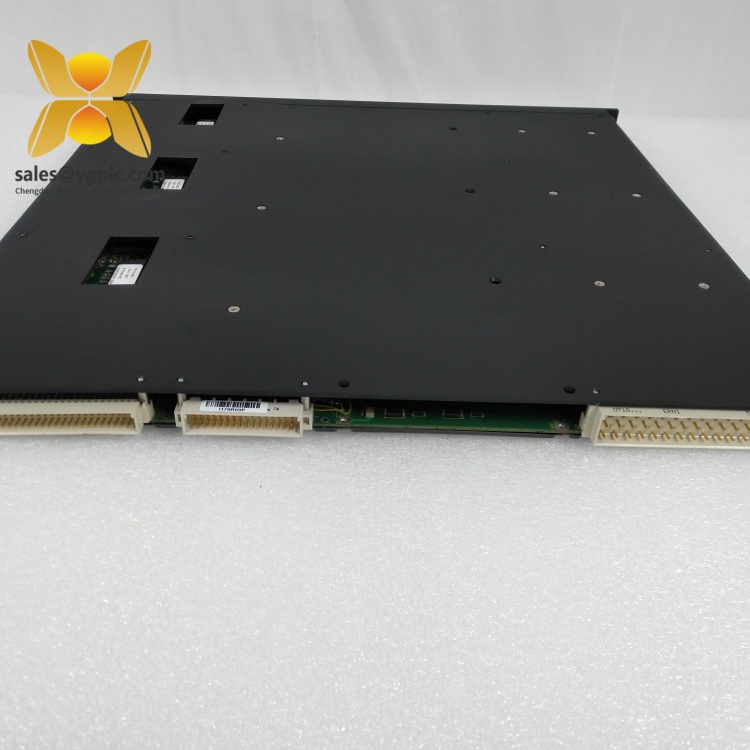

Product Overview: TRICONEX 3805H

The TRICONEX 3805H is a high-reliability Triple Modular Redundancy (TMR) communication interface module designed to enable seamless data exchange between safety instrumented systems (SIS) and external devices in mission-critical industrial environments. As a key component of the TRICONEX Tricon V9 safety platform, this module serves as a bridge between the Tricon controller and various industrial networks, ensuring secure and uninterrupted communication in applications where system downtime or data loss could lead to safety incidents or operational disruptions.

Engineered to meet the rigorous demands of industries such as oil and gas, chemical processing, and power generation, the TRICONEX 3805H supports multiple communication protocols, including Modbus RTU/ASCII, Ethernet/IP, and Profibus DP, making it compatible with a wide range of distributed control systems (DCS), SCADA platforms, and field devices. Its TMR architecture employs three independent communication channels that operate in parallel, with a voting mechanism that validates data integrity and eliminates errors caused by single-channel failures. This redundancy, combined with built-in diagnostics and fault detection, ensures continuous communication even in the event of hardware anomalies, with an availability rating exceeding 99.99%.

In automation systems, the TRICONEX 3805H plays a critical role in enabling real-time data transmission between the SIS and external systems, such as process historians, operator workstations, and emergency shutdown (ESD) panels. It facilitates the transfer of critical process variables, alarm statuses, and diagnostic data, allowing operators to monitor system health and make informed decisions. The module’s hot-swap capability allows for online replacement without disrupting system operation, minimizing downtime. By combining robust communication functionality with TMR fault tolerance, the TRICONEX 3805H enhances system integration, improves operational visibility, and reduces lifecycle costs, making it an essential component for modern high-integrity control solutions.

Technical Specifications: TRICONEX 3805H

| Parameter | Value |

|---|---|

| Manufacturer | TRICONEX |

| Product Type | TMR Communication Interface Module |

| Physical Dimensions | 263 mm × 58 mm × 28 mm (10.35″ × 2.28″ × 1.10″) |

| Weight | 1.5 kg (3.31 lbs) [net]; 3.2 kg (7.05 lbs) [shipping] |

| Power Requirement | 24V DC ±10% |

| Communication Protocols | Modbus RTU/ASCII, Ethernet/IP, Profibus DP |

| Data Transfer Rate | Up to 100 Mbps (Ethernet); 12 Mbps (Profibus DP) |

| Operating Temperature | -40°C to +70°C |

| Certifications | IEC 61508 (SIL 3), CE, UL, ATEX/IECEx (Zone 2) |

| MTBF | >1,000,000 hours (per IEC 61709) |

| Input/Output Ports | 2 Ethernet ports (RJ45), 1 Profibus DP port (D-sub 9), 1 Modbus port (RS-485) |

3805H

Related Products: TRICONEX 3805H

- TRICONEX 3805: A predecessor to the 3805H with basic communication protocols, suitable for legacy systems requiring Modbus-only integration.

- TRICONEX 3806: A high-speed TMR Ethernet module specializing in Ethernet/IP and Modbus TCP, ideal for large-scale data aggregation in modern plants.

- TRICONEX 4351B: A multi-protocol gateway module that extends the 3805H’s connectivity to Foxboro DCS and OPC UA networks.

- TRICONEX 3720: A TMR analog input module that provides process data to the 3805H for transmission to monitoring systems.

- TRICONEX 3601E: A digital output module whose status is communicated by the 3805H to trigger alarms or shutdowns.

- TRICONEX 8310: A redundant power supply module ensuring stable 24V DC power to the 3805H and other Tricon components.

- TRICONEX 9566-712: A dedicated termination panel for the 3805H, offering surge protection and organized wiring for communication ports.

- TRICONEX 2651: A TMR controller module that pairs with the 3805H to process and transmit safety-critical logic.

Main Features and Advantages: TRICONEX 3805H

The TRICONEX 3805H delivers uninterrupted communication reliability through its TMR architecture, which eliminates single points of failure by maintaining three independent communication paths. Each path processes data simultaneously, with a voting algorithm that selects valid data and discards erroneous signals from faulty channels. This design ensures that even if one channel fails, the module continues to operate without data loss, a critical feature for safety-critical applications where communication gaps could delay emergency responses.

Its versatile protocol support allows seamless integration with diverse industrial networks, reducing the need for multiple specialized communication modules. The module’s advanced signal processing minimizes latency, ensuring real-time data transmission with a response time of <50 ms for critical messages. This speed is essential for applications like ESD systems, where rapid status updates between the SIS and DCS can prevent accidents.

The TRICONEX 3805H also excels in diagnostic transparency. Built-in self-tests continuously monitor port status, cable integrity, and protocol errors, providing detailed fault codes via the Tricon controller. This enables proactive maintenance, as technicians can identify issues like loose connections or protocol mismatches before they cause communication failures. Additionally, the module’s conformal coating protects against dust, moisture, and chemical exposure, making it suitable for harsh environments such as offshore platforms and chemical plants.

3805H

Installation and Maintenance: TRICONEX 3805H

Pre-installation Preparations:

Before installing the TRICONEX 3805H, verify that the control system’s power supply provides stable 24V DC ±10% and that the chassis is properly grounded to prevent electromagnetic interference (EMI). Configure network settings (IP address, baud rate, protocol parameters) using TRICONEX’s configuration software to match the target system’s requirements. Use the dedicated termination panel (e.g., TRICONEX 9566-712) for wiring, ensuring proper shielding of communication cables to minimize noise. Update the module’s firmware to the latest version to ensure compatibility with the Tricon V9 platform and access to new protocol features.

Before installing the TRICONEX 3805H, verify that the control system’s power supply provides stable 24V DC ±10% and that the chassis is properly grounded to prevent electromagnetic interference (EMI). Configure network settings (IP address, baud rate, protocol parameters) using TRICONEX’s configuration software to match the target system’s requirements. Use the dedicated termination panel (e.g., TRICONEX 9566-712) for wiring, ensuring proper shielding of communication cables to minimize noise. Update the module’s firmware to the latest version to ensure compatibility with the Tricon V9 platform and access to new protocol features.

Maintenance Suggestions:

Regular maintenance of the TRICONEX 3805H includes visual inspections of ports and connectors for corrosion, damage, or loose connections, especially in high-humidity environments. Use diagnostic tools to monitor communication traffic and error rates, addressing issues like packet loss or latency promptly. Clean the module’s ventilation slots periodically to prevent dust buildup, which can affect thermal performance. For long-term storage, keep the module in a dry environment with humidity below 80% and temperature between -20°C and +60°C, avoiding exposure to direct sunlight or corrosive gases.

Regular maintenance of the TRICONEX 3805H includes visual inspections of ports and connectors for corrosion, damage, or loose connections, especially in high-humidity environments. Use diagnostic tools to monitor communication traffic and error rates, addressing issues like packet loss or latency promptly. Clean the module’s ventilation slots periodically to prevent dust buildup, which can affect thermal performance. For long-term storage, keep the module in a dry environment with humidity below 80% and temperature between -20°C and +60°C, avoiding exposure to direct sunlight or corrosive gases.

Application Fields: TRICONEX 3805H

The TRICONEX 3805H is widely deployed in industries where secure, real-time communication between safety systems and external devices is critical. In oil and gas refineries, it connects the Tricon SIS to DCS platforms, transmitting data on pipeline pressures, valve positions, and leak detections to operator workstations, enabling timely interventions during abnormal conditions. In chemical processing plants, it facilitates communication between reactor safety systems and process historians, ensuring compliance with regulatory requirements for data logging and audit trails.

Power generation facilities rely on the TRICONEX 3805H to link turbine protection systems with SCADA networks, providing real-time updates on vibration levels, temperature readings, and generator status to prevent equipment damage. In LNG terminals, it enables communication between cryogenic storage safety systems and emergency shutdown panels, ensuring rapid coordination during pressure spikes or leaks. The module also finds applications in pharmaceutical manufacturing, where it connects batch processing safety systems to quality control databases, maintaining data integrity for regulatory compliance.

3805H

Product Guarantee: TRICONEX 3805H

Our company offers a one-year quality warranty for the TRICONEX 3805H, covering hardware defects not caused by improper installation, misuse, or environmental damage. During the warranty period, we provide prompt replacement of faulty modules, supported by our extensive global supply chain network to minimize downtime. Our technical support team, with deep expertise in TRICONEX communication modules, offers 24/7 assistance for configuration guidance, protocol troubleshooting, and system integration. As a leading industrial control distributor with 17 years of experience, we maintain large stocks of both active and discontinued models, ensuring rapid fulfillment of urgent spare part requests. Whether for new installations or legacy system upgrades, we are committed to delivering reliable solutions that keep your critical communication networks operational.

Contact Information

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: