Description

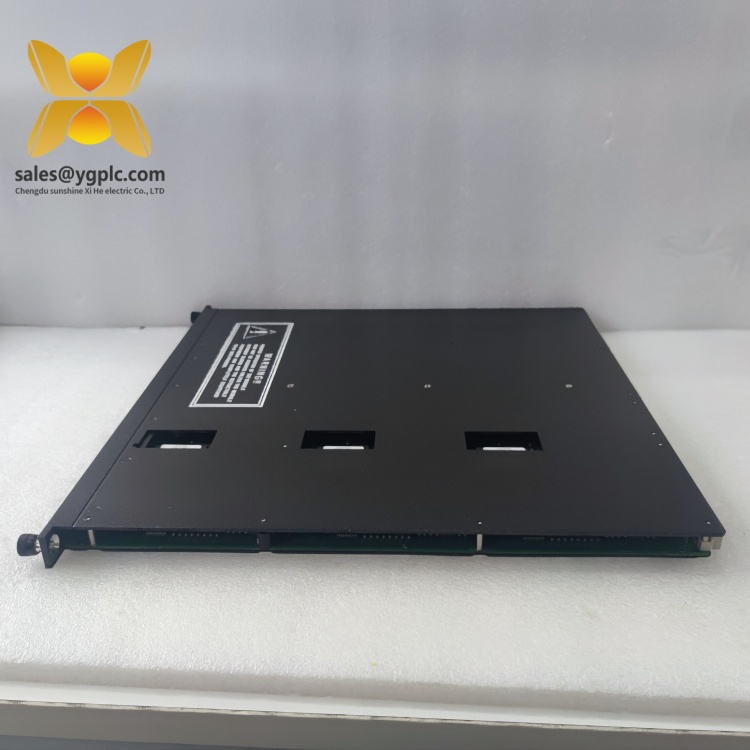

Product Overview: TRICONEX 3700A

The TRICONEX 3700A is a high-performance Triple Modular Redundancy (TMR) analog input module designed for safety-critical applications in industrial automation systems. As a core component of the TRICONEX Tricon V9 platform, this module delivers precise signal conditioning and conversion, ensuring reliable data acquisition for processes where operational continuity is non-negotiable. Engineered to interface with sensors and transmitters in environments such as oil refineries, chemical plants, and power generation facilities, the TRICONEX 3700A supports seamless integration into Safety Instrumented Systems (SIS) and Distributed Control Systems (DCS).

Featuring 32 differential input channels, the TRICONEX 3700A accepts voltage signals ranging from 0–5V DC with a resolution of 12 bits and accuracy within <0.15% of full-scale range (FSR) across temperatures from 0°C to 60°C. Its TMR architecture employs three independent sub-circuits that process signals simultaneously, with a mid-value selection algorithm ensuring data integrity even if one channel fails. The module’s robust design includes comprehensive diagnostics, such as loopback testing for each channel and real-time fault detection, which automatically isolate faulty inputs while maintaining system functionality.

In automation systems, the TRICONEX 3700A serves as a vital link between field sensors (e.g., pressure transducers, thermocouples) and control logic, enabling real-time monitoring of process variables like temperature, flow, and level. Its hot-swap capability allows online replacement of faulty modules without disrupting operations, minimizing downtime in mission-critical scenarios. By combining high-precision signal processing with TMR fault tolerance, the TRICONEX 3700A enhances system availability and reduces lifecycle costs, making it ideal for retrofitting legacy systems or building new high-integrity control solutions.

Technical Specifications: TRICONEX 3700A

| Parameter | Value |

|---|---|

| Manufacturer | TRICONEX |

| Product Type | TMR Analog Input Module |

| Physical Dimensions | 263 mm × 58 mm × 28 mm (10.35″ × 2.28″ × 1.10″) |

| Weight | 2.85 kg (6.28 lbs) [net] |

| Voltage Range | 0–5V DC (differential, DC-coupled) |

| Input Channels | 32 |

| Resolution | 12 bits |

| Accuracy | <0.15% of FSR (0°C to 60°C) |

| Response Time | 55 ms |

| Power Consumption | 25W |

| Certifications | IEC 61508 (SIL 3), CE, UL |

| Communication Protocols | Modbus, Ethernet, OPC UA, MQTT |

3700A

Related Products: TRICONEX 3700A

- TRICONEX 3701: A TMR analog input module supporting 0–10V DC signals, suitable for applications requiring broader voltage measurement ranges.

- TRICONEX 3703E: An isolated TMR analog input module with 16 channels, designed for environments with high electrical noise or ground potential differences.

- TRICONEX 3503E: A digital input module supporting 24V AC/DC signals, used for monitoring discrete inputs like switches and sensors.

- TRICONEX 3601E: A digital output module with optically isolated channels, ideal for driving solenoids and relays in safety-critical systems.

- TRICONEX 4351B: A communication module enabling connectivity with Foxboro DCS, Modbus, and other industrial networks.

- TRICONEX 8310: A high-density power supply module providing 120V AC/DC power to Tricon systems.

- TRICONEX 9566-710: An external termination panel (ETP) for the 3700A, offering surge protection and secure field wiring connections.

Main Features and Advantages: TRICONEX 3700A

The TRICONEX 3700A excels in fault-tolerant signal processing, leveraging its TMR architecture to ensure continuous operation even with partial channel failures. Each input channel undergoes independent diagnostics, including open-circuit detection and overvoltage protection (150V DC/115V AC continuous), which prevent cascading system errors. This proactive approach to reliability reduces mean time to repair (MTTR) and ensures compliance with stringent safety standards.

Its high-precision signal conditioning capabilities make it suitable for applications requiring sub-percent accuracy, such as chemical reactor monitoring and turbine control. The module’s wide common-mode rejection (-80 dB at DC–100 Hz) and high input resistance (30 MΩ) minimize interference from electromagnetic fields, ensuring stable performance in harsh industrial settings.

The TRICONEX 3700A also supports seamless system integration through multiple communication protocols, allowing data exchange with higher-level systems like SCADA or ERP platforms. Its compatibility with TRICONEX’s Tricon V9 platform ensures backward compatibility with legacy systems while supporting modern industrial IoT (IIoT) architectures.

3700A

Installation and Maintenance: TRICONEX 3700A

Pre-installation Preparations:

Before installing the TRICONEX 3700A, verify that the control system’s power supply meets the module’s requirements (24V DC) and that the chassis is properly grounded. Use the recommended external termination panel (e.g., TRICONEX 9566-710) to connect field wiring, following the polarity guidelines in the installation manual. Ensure the module’s firmware is updated to the latest version to support compatibility with the control system.

Before installing the TRICONEX 3700A, verify that the control system’s power supply meets the module’s requirements (24V DC) and that the chassis is properly grounded. Use the recommended external termination panel (e.g., TRICONEX 9566-710) to connect field wiring, following the polarity guidelines in the installation manual. Ensure the module’s firmware is updated to the latest version to support compatibility with the control system.

Maintenance Suggestions:

Regular maintenance of the TRICONEX 3700A includes visual inspections for loose connections or physical damage, particularly in high-vibration environments. Use diagnostic tools to monitor channel health and review event logs for anomalies, such as drift in signal accuracy. Clean the module periodically to prevent dust accumulation, which can affect thermal performance. For long-term storage, store the module in a dry, static-free environment with humidity below 80%.

Regular maintenance of the TRICONEX 3700A includes visual inspections for loose connections or physical damage, particularly in high-vibration environments. Use diagnostic tools to monitor channel health and review event logs for anomalies, such as drift in signal accuracy. Clean the module periodically to prevent dust accumulation, which can affect thermal performance. For long-term storage, store the module in a dry, static-free environment with humidity below 80%.

Application Fields: TRICONEX 3700A

The TRICONEX 3700A is widely adopted in industries where precision and safety are paramount. In oil and gas, it monitors wellhead pressure and flow rates to trigger emergency shutdowns (ESD) during leaks or equipment failures. In chemical manufacturing, it measures reactor temperatures and pressures to prevent runaway reactions, ensuring compliance with OSHA and EPA regulations. Power plants rely on the module to monitor turbine vibrations and generator voltages, protecting critical infrastructure from damage.

The module’s adaptability extends to water treatment facilities, where it controls pump speeds and valve positions to optimize filtration processes, and pharmaceutical production, where it maintains sterile environments by regulating cleanroom airflow systems. Its high-density design and TMR redundancy also make it suitable for mining and metallurgy, where it manages conveyor systems and heavy machinery in dusty, high-moisture conditions.

3700A

Product Guarantee: TRICONEX 3700A

Our company offers a one-year quality warranty for the TRICONEX 3700A, covering hardware malfunctions unrelated to misuse or environmental damage. During the warranty period, we provide prompt replacement services for defective modules, supported by our global supply chain network to expedite delivery of scarce spare parts. Our technical support team offers 24/7 assistance for installation, troubleshooting, and system integration, ensuring seamless deployment across diverse industrial applications. With 17 years of experience in industrial control distribution, we are committed to delivering reliable solutions that keep operations compliant and efficient.

Contact Information

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

WhatsApp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: