Description

TRICONEX 3636T Product Description

Product Overview

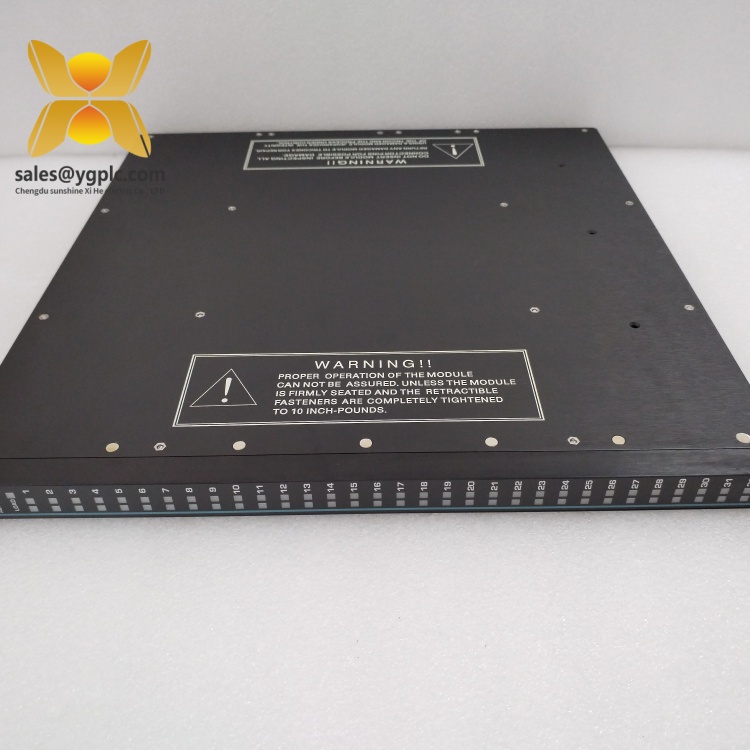

The TRICONEX 3636T is a critical component within TRICONEX’s renowned Tricon safety instrumented system (SIS), designed to deliver uncompromising reliability in industrial environments where safety and operational continuity are paramount. As a key module in the TRICONEX portfolio, the TRICONEX 3636T plays a vital role in monitoring and processing critical signals within safety-critical automation setups, ensuring that industrial processes adhere to strict safety standards.

This module is engineered to integrate seamlessly with the Tricon system architecture, which is widely recognized for its triple-modular redundancy (TMR) design—eliminating single points of failure and minimizing the risk of unplanned shutdowns. The TRICONEX 3636T excels in translating field data into actionable insights, supporting real-time decision-making in high-risk operations. Its robust construction and advanced diagnostics make it a cornerstone of safety and control systems, providing industrial operators with the confidence to manage complex processes while maintaining compliance with global safety regulations. Whether deployed in hazardous or non-hazardous areas, the TRICONEX 3636T delivers consistent performance, making it an indispensable asset for modern industrial automation.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | TRICONEX 3636T |

| Manufacturer | TRICONEX (Schneider Electric) |

| Product Type | Digital Input Module (Safety-Critical) |

| Power Requirements | 24V DC ±10% |

| Operating Temperature | -40°C to 70°C (-40°F to 158°F) |

| Communication Protocol | Tricon System Bus |

| Digital Input Channels | 16 Channels |

| Safety Certification | SIL 3 (per IEC 61508) |

| Mounting Type | Tricon System Rack Mount |

| Dimensions | 160mm × 100mm × 30mm (L×W×H) |

| Weight | Approx. 0.5 kg (1.1 lbs) |

| Redundancy Support | Compatible with TMR Architecture |

| Diagnostic Capabilities | Real-time channel-level fault detection |

3636T

Key Features and Benefits

The TRICONEX 3636T stands out for its unwavering commitment to safety and reliability, making it a preferred choice for mission-critical applications. At its core is its compliance with SIL 3 certification, the highest safety integrity level for industrial systems, ensuring it can mitigate risks in environments where failure could lead to catastrophic consequences. This certification underscores its ability to perform reliably under extreme conditions, a testament to TRICONEX’s engineering expertise.

Another defining feature is its advanced diagnostic system, which provides real-time channel-level monitoring. This allows operators to quickly identify and address issues such as open circuits or signal loss without disrupting overall system operation, minimizing downtime and enhancing maintenance efficiency. The module’s compatibility with TRICONEX’s TMR architecture adds an extra layer of security, as redundant components ensure continuous operation even if a single module fails.

Integration with existing Tricon systems is seamless, thanks to the Tricon System Bus protocol, which enables smooth communication with controllers and other I/O modules. This plug-and-play functionality reduces installation time and simplifies system upgrades. Additionally, the TRICONEX 3636T’s rugged design—with wide temperature tolerance and robust construction—ensures durability in harsh industrial environments, from refineries to power plants.

Application Scenarios

The TRICONEX 3636T is engineered for deployment in safety-critical industrial environments where precision monitoring and fault tolerance are non-negotiable. In oil and gas refineries, it plays a critical role in monitoring pressure, temperature, and flow sensors in processing units, ensuring that potentially hazardous conditions are detected immediately to prevent leaks or explosions. Its SIL 3 certification makes it ideal for these applications, where regulatory compliance and operational safety are tightly regulated.

In power generation facilities, both fossil fuel and nuclear, the TRICONEX 3636T monitors critical inputs from turbine control systems, boiler safety valves, and emergency shutdown mechanisms. Its ability to operate reliably in extreme temperatures ensures consistent performance even in the high-heat environments of power plant operations.

Chemical processing plants also benefit significantly from the TRICONEX 3636T, as it monitors chemical storage tank levels, valve positions, and reaction chamber pressures. By providing accurate, real-time data to the Tricon SIS, it enables rapid response to deviations from safe operating parameters, protecting both personnel and equipment. In all these scenarios, the TRICONEX 3636T serves as a linchpin in maintaining safe, efficient, and compliant industrial operations.

Related Models

- TRICONEX 3625 – Previous generation digital input module with 8 channels, compatible with legacy Tricon systems.

- TRICONEX 3635 – Analog input module, complementary to TRICONEX 3636T for monitoring continuous process variables.

- TRICONEX 3646 – Digital output module, works with TRICONEX 3636T to execute safety shutdown commands.

- TRICONEX 3721 – Communication module that enhances data transmission between TRICONEX 3636T and Tricon controllers.

- TRICONEX 3805E – Power supply module, provides stable power to TRICONEX 3636T and other Tricon I/O modules.

- TRICONEX 4351B – Safety controller module, the central processing unit that integrates data from TRICONEX 3636T.

- TRICONEX 2651 – Relay output module, often paired with TRICONEX 3636T for high-power safety actuation.

3636T

Installation and Maintenance

Installation of the TRICONEX 3636T requires careful preparation to ensure optimal performance. The module must be mounted in a compatible Tricon system rack, with sufficient space for airflow to prevent overheating. Proper grounding is essential to minimize electrical interference, as noise can compromise signal accuracy in safety-critical applications. Before installation, verify that the operating environment meets the module’s temperature and humidity specifications (-40°C to 70°C) to avoid premature failure.

For maintenance, regular diagnostics using TRICONEX’s system software are recommended to monitor channel health and detect potential faults early. Visual inspections should check for loose connections or signs of corrosion, particularly in dusty or humid environments. Clean the module’s connectors periodically with approved electronics cleaning solutions to maintain signal integrity. While the TRICONEX 3636T is designed for long-term reliability, replacement intervals should align with system-wide maintenance schedules, typically every 5–7 years, to ensure continued compliance with safety standards.

Product Warranty

The TRICONEX 3636T is backed by a one-year warranty from Xiamen Xiongba E-commerce Co., Ltd., which includes free replacement service for any defects in materials or workmanship under normal operating conditions. This warranty reflects our confidence in the product’s quality and reliability, ensuring customers receive support throughout the initial operational period. Our global support network provides technical assistance for installation, troubleshooting, and system integration, ensuring minimal downtime and optimal performance. We are committed to customer satisfaction, leveraging our direct sourcing capabilities and industry expertise to address any issues promptly. This warranty coverage, combined with our dedication to quality, makes the TRICONEX 3636T a trusted investment for critical industrial automation needs.

About the Supplier

Xiamen Xiongba E-commerce Co., Ltd. specializes in the industrial automation sector, focusing on the sales of Distributed Control Systems (DCS), robot systems, and modules and spare parts for large-scale servo control systems. Our business encompasses a wide range of industrial automation products, including PLCs, MOTOROLA MVME industrial modules, Anybus communication converters, RTU remote modules, industrial PCs, low-frequency industrial displays, and SCSI human-machine interfaces.

With over a decade of industry experience, Xiongba has evolved into a global supplier of industrial automation spare parts. We source directly from overseas, offering products and parts from multiple countries and manufacturers. This approach addresses customers’ procurement challenges, ensures product quality, and provides significant price advantages, solidifying our position as a reliable partner in the industrial automation landscape.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: