Description

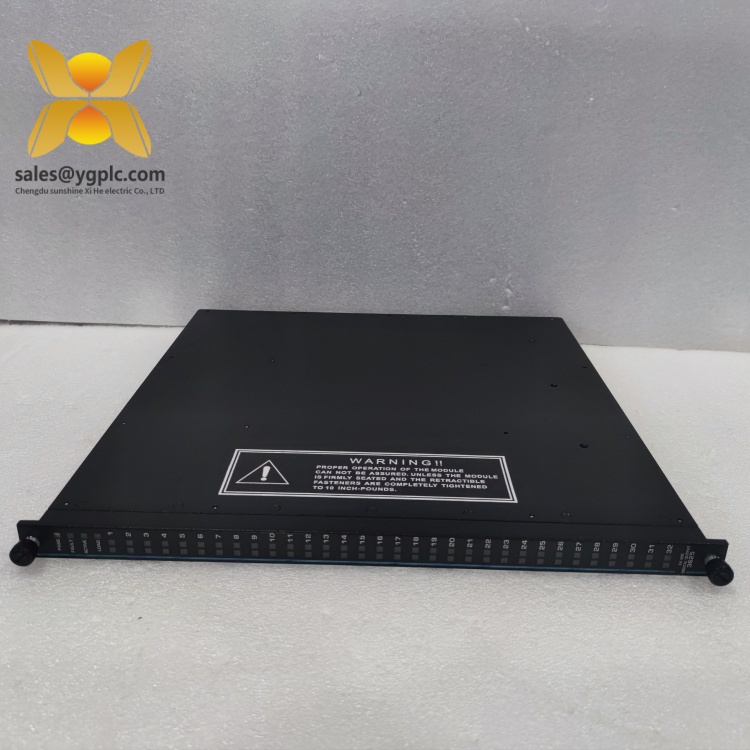

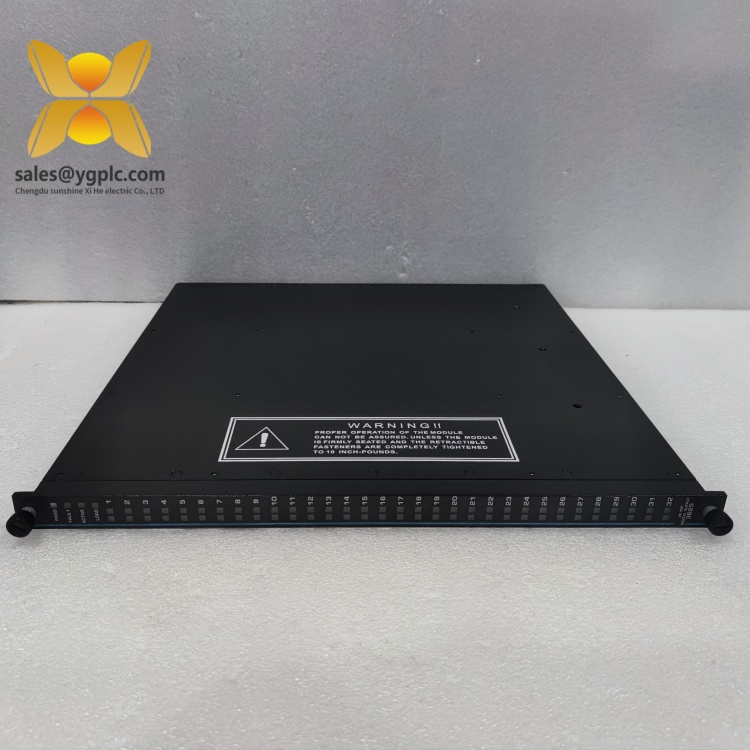

Product Overview: TRICONEX 3626X

The TRICONEX 3626X is a high-performance digital output module engineered for mission-critical industrial automation and safety instrumented systems (SIS). As part of TRICONEX’s Trident series, this module leverages Triple Modular Redundancy (TMR) technology to deliver SIL 3-certified reliability, making it ideal for applications where system failure could lead to catastrophic consequences. Designed for seamless integration into complex control architectures, the TRICONEX 3626X ensures precise, deterministic control of industrial processes while maintaining compliance with international safety standards like IEC 61508 .

The TRICONEX 3626X is a high-performance digital output module engineered for mission-critical industrial automation and safety instrumented systems (SIS). As part of TRICONEX’s Trident series, this module leverages Triple Modular Redundancy (TMR) technology to deliver SIL 3-certified reliability, making it ideal for applications where system failure could lead to catastrophic consequences. Designed for seamless integration into complex control architectures, the TRICONEX 3626X ensures precise, deterministic control of industrial processes while maintaining compliance with international safety standards like IEC 61508 .

With 16 isolated output channels, the TRICONEX 3626X supports both dry contact and solid-state relay configurations, accommodating up to 0.5A per channel for direct actuation of valves, motors, and alarms. Its compact form factor (120 mm x 80 mm x 60 mm) and lightweight design (0.5 kg) facilitate installation in space-constrained environments, while 1500V AC isolation safeguards against electrical interference. The module’s dual-port Ethernet connectivity enables real-time data exchange with higher-level systems, ensuring synchronization with supervisory control platforms .

In safety-critical industries such as oil and gas, chemical processing, and power generation, the TRICONEX 3626X serves as a cornerstone for emergency shutdown systems (ESD), burner management systems (BMS), and high-integrity pressure protection systems (HIPPS). Its self-diagnostic capabilities continuously monitor for faults, reducing mean time to repair (MTTR) and minimizing downtime. By combining robust hardware with TRICONEX’s proven TMR architecture, the 3626X ensures uninterrupted operation even in harsh conditions, where temperature fluctuations, humidity, and vibration are common .

Technical Specifications

- Manufacturer: TRICONEX

- Product type: Digital Output Module

- Operating voltage: 24 VDC

- Number of channels: 16

- Output type: Dry contact/solid-state relay

- Max switching current: 0.5 A per channel

- Isolation voltage: 1500V AC

- Certifications: IEC 61508 SIL 3, CE, UL, ATEX

- Physical dimensions: 120 mm x 80 mm x 60 mm

- Weight: 0.5 kg

- Communication protocols: Modbus RTU/TCP, Ethernet/IP

- Operating temperature: -40°C to +85°C

- Installation: DIN rail mountable

3626X

Related Products

- TRICONEX 3625: A 16-channel digital output module with similar specifications but without TMR redundancy, suitable for non-safety-critical applications.

- TRICONEX 3636R: A 32-channel relay output module offering higher switching capacity for heavy-duty loads.

- TRICONEX 3503E: A 32-channel digital input module designed for compatibility with the 3626X in hybrid I/O systems.

- TRICONEX 3604E: A 16-channel digital output module with 24V DC isolation, optimized for process control applications.

- TRICONEX 3700A: An analog input module that pairs with the 3626X for integrated process monitoring and control.

- TRICONEX 8311: A high-density power supply module providing redundant power to the 3626X and other TMR components.

- TRICONEX 4119: An enhanced communication module enabling seamless integration with third-party systems.

Main Features and Advantages

The TRICONEX 3626X stands out for its uncompromising reliability and versatility. Its TMR architecture ensures that even if one of its three processing channels fails, the module continues operating without interruption, a critical feature in industries where downtime equates to significant financial loss or safety risks . The module’s SIL 3 certification guarantees compliance with the most stringent safety standards, making it a preferred choice for applications like offshore platforms and chemical reactors.

The TRICONEX 3626X stands out for its uncompromising reliability and versatility. Its TMR architecture ensures that even if one of its three processing channels fails, the module continues operating without interruption, a critical feature in industries where downtime equates to significant financial loss or safety risks . The module’s SIL 3 certification guarantees compliance with the most stringent safety standards, making it a preferred choice for applications like offshore platforms and chemical reactors.

Another key strength is its diagnostic depth. The 3626X continuously monitors channel health, voltage levels, and thermal conditions, flagging anomalies through its built-in LED indicators. This proactive approach reduces maintenance costs by enabling predictive interventions rather than reactive repairs. Additionally, the module’s hot-swap capability allows for component replacement without shutting down the entire system, further enhancing operational uptime .

The TRICONEX 3626X also excels in ease of integration. Its support for multiple communication protocols ensures compatibility with legacy and modern control systems alike. For example, it can interface with Schneider Electric’s EcoStruxure platform or Rockwell Automation’s PlantPAx, providing a unified view of process data. This flexibility makes it suitable for retrofitting aging infrastructure as well as greenfield projects .

3626X

Installation and Maintenance

Pre-installation preparations:

Before installing the TRICONEX 3626X, verify the compatibility of your system’s power supply (24 VDC ±10%) and ensure the enclosure meets environmental requirements (e.g., IP65 for outdoor use). Use a termination board like the HiCTB16-TRX-RAC-PL-DO16 to simplify wiring and protect against voltage spikes. Conduct a thorough check of the DIN rail mounting brackets to ensure secure fixation.

Pre-installation preparations:

Before installing the TRICONEX 3626X, verify the compatibility of your system’s power supply (24 VDC ±10%) and ensure the enclosure meets environmental requirements (e.g., IP65 for outdoor use). Use a termination board like the HiCTB16-TRX-RAC-PL-DO16 to simplify wiring and protect against voltage spikes. Conduct a thorough check of the DIN rail mounting brackets to ensure secure fixation.

Maintenance suggestions:

Regular maintenance involves inspecting the module’s LED indicators for fault signals and cleaning dust from ventilation slots. Firmware updates should be applied periodically to address security patches and performance optimizations. For systems operating in corrosive environments, consider using conformal coating to extend component lifespan. In the event of a hardware failure, replace the module with a pre-tested spare from your inventory to minimize downtime. TRICONEX recommends annual functional testing to validate the module’s response times and redundancy mechanisms .

Regular maintenance involves inspecting the module’s LED indicators for fault signals and cleaning dust from ventilation slots. Firmware updates should be applied periodically to address security patches and performance optimizations. For systems operating in corrosive environments, consider using conformal coating to extend component lifespan. In the event of a hardware failure, replace the module with a pre-tested spare from your inventory to minimize downtime. TRICONEX recommends annual functional testing to validate the module’s response times and redundancy mechanisms .

Application Fields

The TRICONEX 3626X finds extensive use in industries where safety and precision are non-negotiable. In oil and gas, it controls emergency shutdown valves and gas compressor trips, preventing leaks and explosions. In chemical manufacturing, it manages reactor agitators and cooling systems, ensuring process stability. Power plants rely on the 3626X to operate turbine bypass valves and boiler safety interlocks, maintaining grid stability during load fluctuations .

The TRICONEX 3626X finds extensive use in industries where safety and precision are non-negotiable. In oil and gas, it controls emergency shutdown valves and gas compressor trips, preventing leaks and explosions. In chemical manufacturing, it manages reactor agitators and cooling systems, ensuring process stability. Power plants rely on the 3626X to operate turbine bypass valves and boiler safety interlocks, maintaining grid stability during load fluctuations .

Marine applications, such as offshore drilling rigs, benefit from its rugged design, which withstands saltwater corrosion and extreme vibrations. Pharmaceutical facilities use the module to automate sterilization processes and cleanroom environmental controls, adhering to FDA and EU GMP standards. Even in mining, the 3626X ensures safe operation of conveyor systems and ventilation fans in underground tunnels .

Across these sectors, the TRICONEX 3626X solves two core challenges: risk mitigation through redundant control and operational efficiency through real-time data exchange. Its ability to interface with both analog and digital devices makes it a versatile component in hybrid automation ecosystems.

3626X

Product Guarantee

Our company, a leading industrial control distributor with 17 years of expertise, offers a one-year quality warranty for the TRICONEX 3626X. This coverage includes replacement of hardware defects arising from material or manufacturing issues. For discontinued models like the 3626X, we maintain a global supply chain network to source rare components within 24–48 hours, ensuring minimal disruption to your operations.

Our company, a leading industrial control distributor with 17 years of expertise, offers a one-year quality warranty for the TRICONEX 3626X. This coverage includes replacement of hardware defects arising from material or manufacturing issues. For discontinued models like the 3626X, we maintain a global supply chain network to source rare components within 24–48 hours, ensuring minimal disruption to your operations.

Our technical support team provides 24/7 remote diagnostics and on-site commissioning assistance, ensuring seamless integration. With a 99.9% order fulfillment rate and ISO-certified quality processes, we guarantee that every TRICONEX 3626X delivered meets OEM specifications. Trust us to keep your systems running safely and efficiently, backed by a legacy of reliability in industrial automation.

Contact us at sales@ygplc.com or +86 18859254943 for inquiries.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: