Description

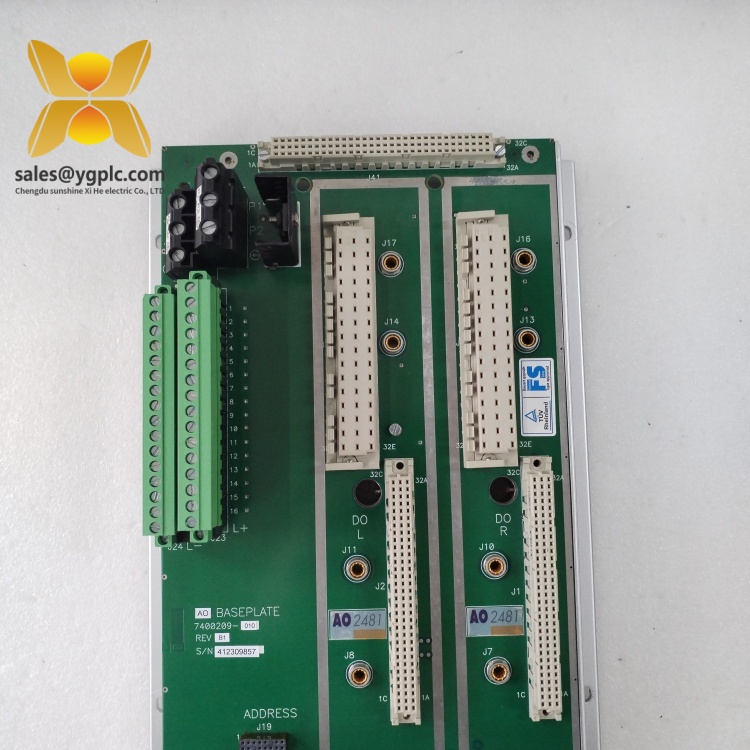

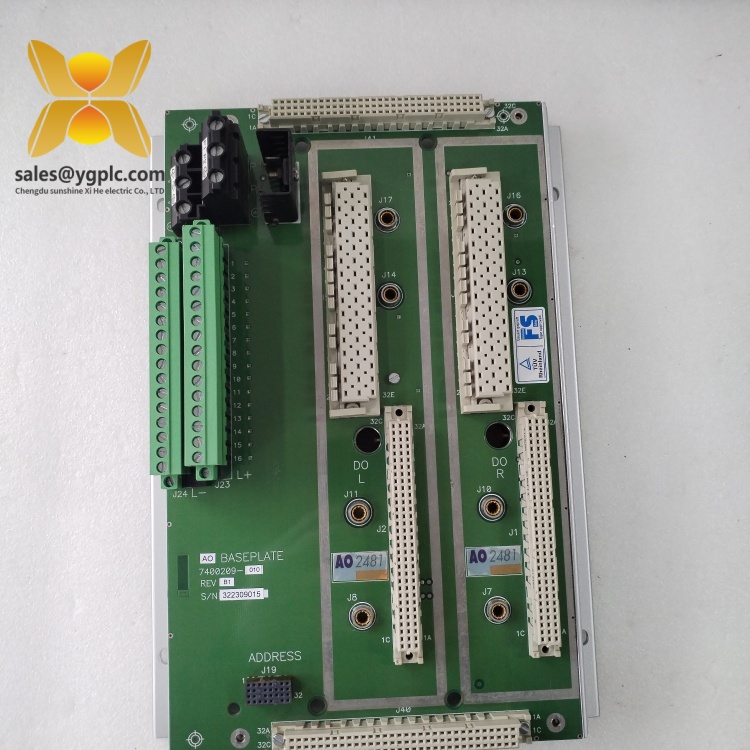

TRICONEX 2481 Analog Output Baseplate Module

Product Overview

The TRICONEX 2481 is a high-reliability analog output baseplate module designed for TRICONEX’s Tricon Triple Modular Redundancy (TMR) safety systems, a cornerstone of safety instrumented systems (SIS) in industrial automation. Serving as a critical interface between Tricon controllers and field actuators, this baseplate supports analog output modules like the TRICONEX 3481 and 2483, enabling precise control of signals for valves, motor drives, and other process equipment in high-risk environments.

As a core component of the Tricon architecture, the TRICONEX 2481 integrates seamlessly with Tricon racks and processors (e.g., TRICONEX 3008), ensuring redundant signal processing to eliminate single points of failure. It supports 24 V DC power supply and HART communication protocol, allowing compatibility with modern smart field devices while maintaining backward compatibility with legacy systems. The module’s design emphasizes durability, with channel-to-backplane isolation (250 V AC) to resist electrical noise and ground loops, ensuring stable operation near high-voltage equipment or large motors.

Built for harsh industrial environments, the TRICONEX 2481 operates in temperatures from -40°C to 70°C and humidity up to 95% (non-condensing). Its SIL 3 certification (IEC 61508) underscores its suitability for critical applications where failure could lead to personnel harm or environmental damage. Though a legacy model, the TRICONEX 2481 remains vital for maintaining older Tricon systems, offering flexibility to support both analog and digital control strategies without full-system upgrades.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 2481 |

| Manufacturer | TRICONEX |

| Product Type | Analog Output Baseplate Module (Tricon TMR System) |

| Power Supply | 24 V DC ±10% |

| Communication Protocol | HART 7.0 |

| Isolation | 250 V AC (channel-to-backplane) |

| Physical Dimensions | 160 mm (L) × 100 mm (W) × 35 mm (D) |

| Weight | 1.0 kg |

| Operating Temperature | -40°C to 70°C |

| Humidity Tolerance | 5%–95% (non-condensing) |

| Safety Integrity Level | SIL 3 (IEC 61508) |

| Mounting Type | Tricon rack mount (compatible with Tricon 1000/2000 racks) |

2481

Related Products

- TRICONEX 3481: A 4-channel analog output module that pairs with the 2481 to deliver precise control signals for valves and actuators in process automation.

- TRICONEX 2483: A HART-enabled analog output module that works with the 2481 to support smart field devices, enabling remote diagnostics and configuration.

- TRICONEX 3008: The Tricon TMR main processor module that sends control commands to the 2481-based output modules for emergency shutdown (ESD) systems.

- TRICONEX 2101: An 8-channel digital input module that complements the 2481 by providing status inputs (e.g., switch positions) to trigger output actions.

- TRICONEX 9662: A power supply module that delivers 24 V DC to the 2481 and other Tricon components, ensuring stable power distribution.

- TRICONEX 8111C: A communication module that relays output status data from the 2481 to SCADA systems for remote monitoring.

Main features and advantages

High-reliability TMR architecture: The 2481 leverages Tricon’s Triple Modular Redundancy, with three independent signal paths processing commands simultaneously. If one path fails, the other two ensure continuous operation—critical for applications like emergency valve control in oil pipelines, where a single failure could cause spills.

HART communication capability: By supporting HART protocol, the 2481 enables integration with smart field devices (e.g., HART-compatible valves), allowing real-time diagnostics and predictive maintenance. This reduces downtime by identifying potential issues before they escalate, such as detecting a valve’s degraded performance in a chemical reactor.

Wide compatibility: The baseplate supports multiple analog output modules (e.g., 3481, 2483), accommodating diverse signal ranges (4–20 mA, 0–10 V DC) and channel counts. This flexibility makes it suitable for hybrid systems requiring both analog and digital control, such as in power plants where analog signals adjust turbine speeds while digital signals monitor safety interlocks.

Rugged industrial design: The 2481 operates in extreme temperatures (-40°C to 70°C) and resists humidity, ensuring reliability in environments ranging from arctic oil platforms to desert solar farms. Its 250 V AC isolation protects against electrical noise, critical in settings with heavy machinery or welding equipment.

Hot-swappable functionality: The module can be replaced while the system is operational, minimizing downtime during maintenance. This is especially valuable in continuous processes like natural gas processing, where unplanned stops cost thousands of dollars per hour.

2481

Installation and maintenance

Pre-installation preparations: Verify the 2481 is compatible with your Tricon rack (e.g., Tricon 2000) and power supply (24 V DC ±10%). Power off the system and disconnect all power sources. Align the module with an empty I/O slot in the rack and push firmly until it clicks into the backplane. Connect the power supply and HART communication cables, ensuring proper grounding to reduce electromagnetic interference. Use shielded cables for signal connections to maintain integrity in noisy environments.

Maintenance suggestions: Inspect the 2481 quarterly. Clean dust from its surface with a dry cloth to prevent overheating. Check terminal screws for tightness—loose connections can cause intermittent signal loss (e.g., a valve failing to respond). Use Tricon’s diagnostic software to monitor module health; if an output channel shows errors, test the connected actuator first. If the actuator is functional, power off the system, remove the 2481, and reinsert it to resolve potential backplane connection issues. Store a spare 2481 in a dry, cool area (10–30°C) for quick replacement during failures, minimizing process interruptions.

Application fields

The TRICONEX 2481 is widely used in industries requiring reliable analog output control for safety and efficiency:

- Oil and gas: In offshore platforms, the 2481 supports 3481 modules to control hydraulic valves in subsea wellheads. It adjusts valve positions based on pressure data from analog input modules, ensuring safe flow regulation during extraction.

- Chemical processing: In pharmaceutical plants, the baseplate pairs with 2483 modules to control reactor agitator speeds via HART communication. This allows precise mixing of ingredients while enabling remote diagnostics to ensure compliance with sterile manufacturing standards.

- Power generation: In coal-fired plants, the 2481 works with 3481 modules to adjust steam turbine governor valves. It uses temperature and pressure data from analog input modules to optimize energy output, reducing fuel consumption and emissions.

- Water treatment: In wastewater facilities, the 2481 controls sludge pump motors via 3481 modules. It starts pumps when float switches (monitored by digital input modules) detect high sludge levels, preventing overflow and maintaining treatment efficiency.

2481

Product guarantee

Our company offers a one-year quality warranty service for the 2481, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

Our company is a leading enterprise in the industrial control industry, established in 2007, has been 17 years. We are an import and export trade distribution company, mainly selling major brands of industrial control parts, there are many unpopular discontinued models, with a large stock. Our company has the advantage of supply channels, a large number of spot, to meet the needs of customers anxious to find spare parts. Our main PLC module, DCS card, ESD system card, vibration monitoring system card, turbine control system module, gas generator spare parts, instruments and other products distribution trade.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: