Description

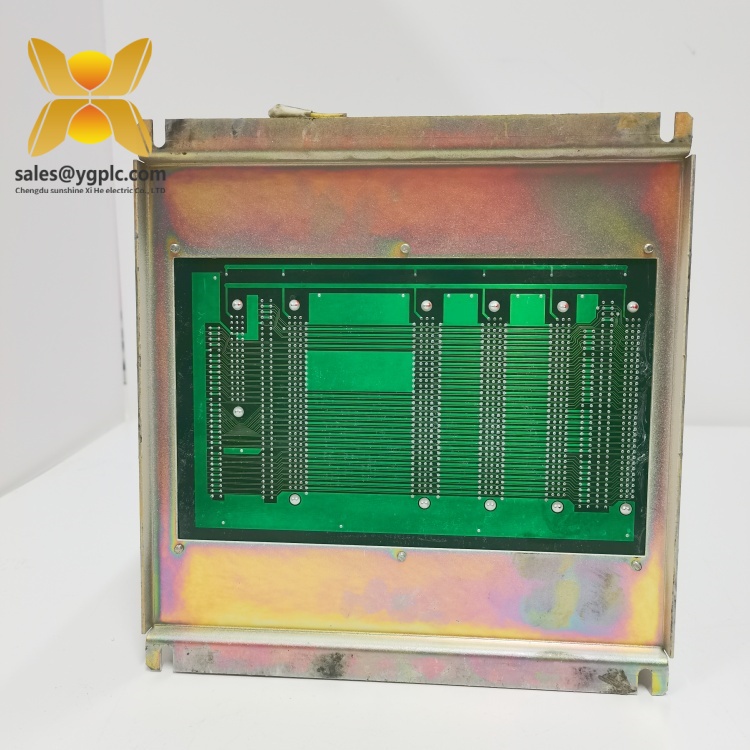

Product Overview: RELIANCE S-D4039

Technical Specifications: RELIANCE S-D4039

| Parameter Name | Parameter Value |

|---|---|

| Product Model | S-D4039 |

| Manufacturer | RELIANCE |

| Product Type | Industrial Drive Module |

| Input Voltage | 200–240V AC (single-phase), 50/60 Hz |

| Output Power | Up to 7.5 kW |

| Control Technology | Vector control, V/f control |

| Communication Interfaces | RS485, Ethernet (Modbus TCP/IP) |

| Motor Compatibility | AC induction motors, DC brushed motors |

| Physical Dimensions | 200 mm (H) × 150 mm (W) × 100 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -20°C to +50°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Panel-mounted or DIN rail |

| Country of Origin | United States |

RELIANCE S-D4039

Main Features and Advantages: RELIANCE S-D4039

User-Friendly Configuration: The module’s intuitive interface, including a backlit LCD keypad and dedicated configuration software, simplifies setup and maintenance. Users can quickly program parameters like acceleration/deceleration rates and motor protection settings, while built-in diagnostic tools (e.g., fault codes, real-time status LEDs) streamline troubleshooting and reduce technical dependency.

RELIANCE S-D4039

Application Areas: RELIANCE S-D4039

- Manufacturing: Powers conveyor belts, robotic arms, and CNC machine spindles, ensuring smooth operation in high-speed assembly lines. Its quick response to load changes maintains production consistency in automotive, pharmaceutical, and food & beverage sectors.

- Power Generation: Controls auxiliary systems in steam and gas turbines, such as cooling pumps and ventilation fans, optimizing energy output while withstanding high-temperature environments.

- Oil and Gas: Deployed in offshore platforms and refineries to regulate pump and compressor speeds, ensuring stable fluid flow and pressure management. The module’s communication capabilities enable integration with safety systems for real-time hazard mitigation.

- Water Treatment: Manages pumps and agitators in water/wastewater plants, adjusting speeds to match demand and comply with environmental regulations. Its corrosion-resistant components ensure longevity in humid, chemically active environments.

- Material Handling: Drives conveyor systems in warehouses and logistics centers, providing precise start-stop control to minimize product damage and enhance throughput. The module’s compact design fits easily into space-constrained control panels.

RELIANCE S-D4039

Related Products: RELIANCE S-D4039

- RELIANCE S-D4040: A higher-power variant (up to 15 kW) for heavy-duty applications like industrial crushers and large-scale conveyors, offering expanded I/O capabilities.

- RELIANCE S-D3039: A compact model (up to 5.5 kW) designed for small-to-medium machinery, ideal for packaging equipment or textile mills.

- RELIANCE S-D4039-IO: Features additional digital/analog I/O channels for complex setups, enabling direct integration with more sensors and actuators in automated production lines.

- RELIANCE S-D4039-F: A hazardous-area-certified version (ATEX/IECEx) for use in explosive environments, such as chemical plants or fuel storage facilities.

- RELIANCE S-D4039-C: A cost-optimized model with basic V/f control, suitable for simple speed-regulation tasks in agricultural or light industrial settings.

- RELIANCE S-D4039-B: Includes built-in brake control for applications requiring rapid stopping, such as elevators or hoists, enhancing safety and precision.

Installation and Maintenance: RELIANCE S-D4039

Before installing the S-D4039, verify that the power supply (200–240V AC) matches the module’s specifications and that the installation area meets ventilation requirements to prevent overheating. Clean the mounting surface and secure the module to a DIN rail or panel using the provided brackets, leaving at least 50 mm of clearance for heat dissipation. Connect power cables to the labeled terminals (L1, L2 for input; T1, T2 for output), ensuring proper grounding to minimize electromagnetic interference. Finally, establish communication links using shielded cables and configure the module’s address via the keypad or software.

Maintenance Recommendations:

Regular maintenance ensures optimal performance of the S-D4039. Conduct monthly visual inspections for loose connections, frayed cables, or signs of overheating (e.g., discolored components). Clean the enclosure’s vents with compressed air to remove dust buildup, which can impair cooling efficiency. Every six months, verify communication connectivity and update firmware via Reliance’s official software to access bug fixes and new features. In case of a fault (indicated by an error code on the LCD), reference the user manual to diagnose issues like overloads or sensor failures. For component replacement, ensure the new S-D4039 is calibrated to the same parameters as the original to maintain system consistency.

RELIANCE S-D4039

Product Guarantee: RELIANCE S-D4039

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

ABB 500CPU05 1MRB150081R1E System

BENTLY 1900/65A-00-01-01-01-01 DCS

TeIKOOR CPCIAC-6U-500 900-7002-10 rack

TRICONEX PLM3900N Remote module

Valmet D202593 Main processor

ABB INSUMMCU2 Pulse input

Emerson FX-316 960132-01 Digital quantity

GE IS420UCSBH4A Tachometer sensor

GE IS200TSVCH1AED Digital relay output module

GE IS200TRPGH1BDD S1C5029 Output module digit

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: