Description

Motorola IPMC712 Product Specification

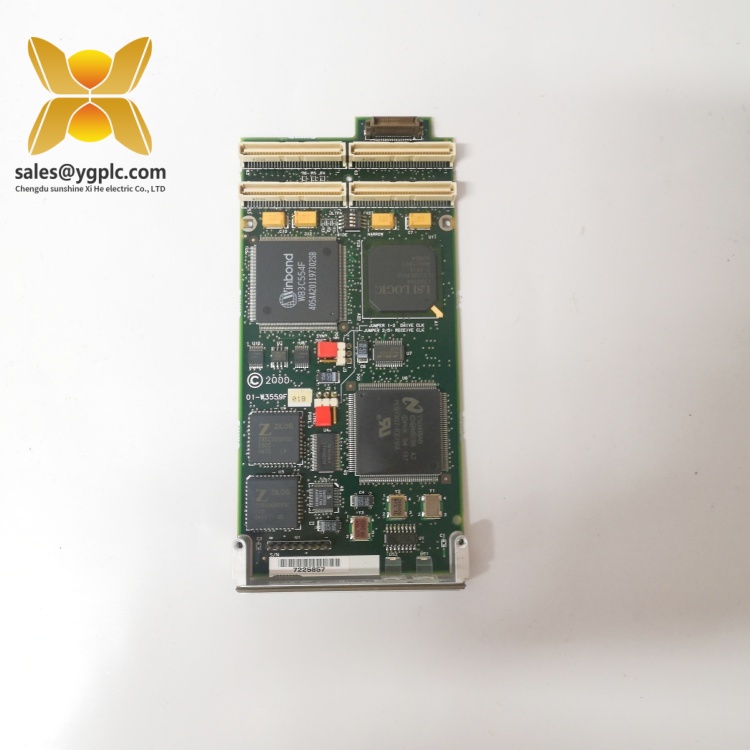

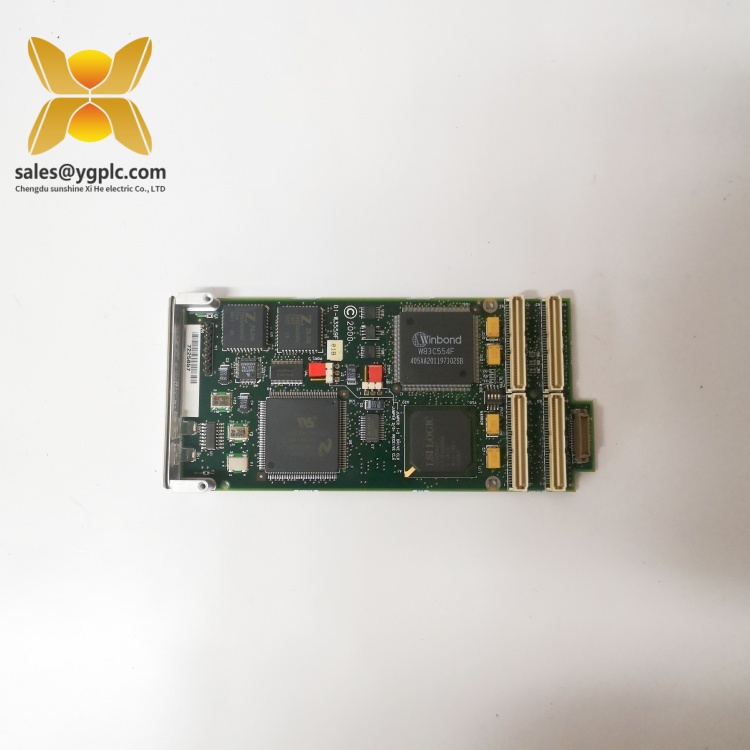

Product Overview:Motorola IPMC712

The Motorola IPMC712 is a ruggedized industrial programmable machine controller designed for demanding automation environments. As part of Motorola’s MVME 系列 (MVME Series) of embedded computing solutions, the IPMC712 combines high-performance processing with industrial-grade durability, making it ideal for real-time control, data acquisition, and machine automation tasks. Engineered to withstand harsh conditions while delivering reliable performance, this controller serves as a critical component in industrial systems where precision, longevity, and adaptability are essential.

At its core, the Motorola IPMC712 features a PowerPC 750GX processor running at 667 MHz, providing robust computational power for executing complex control algorithms and managing multiple simultaneous tasks. It integrates 512 MB DDR SDRAM and 256 MB Flash memory, ensuring efficient data handling and storage for real-time applications. The controller supports a wide range of communication protocols, including Ethernet, RS-232/485, and USB, enabling seamless integration with field devices, human-machine interfaces (HMIs), and supervisory control systems. Its compact form factor (146 mm x 101 mm x 38 mm) and DIN rail mounting design facilitate easy installation in tight industrial enclosures, while its fanless architecture minimizes maintenance requirements and reduces failure points.

In automation systems, the Motorola IPMC712 acts as a centralized control hub, managing machine operations across industries such as manufacturing, energy, and transportation. Its real-time operating system (RTOS) support ensures deterministic performance, critical for applications requiring precise timing and responsiveness, such as robotics, conveyor systems, or process control. By combining rugged hardware with flexible software compatibility, the IPMC712 empowers industries to optimize productivity, reduce downtime, and enhance system reliability in even the most challenging environments.

Technical Specifications:Motorola IPMC712

| Parameter Name | Parameter Value |

|---|---|

| Product Model | Motorola IPMC712 |

| Manufacturer | Motorola |

| Product Type | Industrial Programmable Machine Controller |

| Processor | PowerPC 750GX, 667 MHz |

| Memory | 512 MB DDR SDRAM, 256 MB Flash |

| Communication Interfaces | 2 x 10/100/1000Base-T Ethernet, 2 x RS-232/485, 1 x USB 2.0 |

| Power Supply | 24 VDC ±20% (18–36 VDC range) |

| Physical Dimensions | 146 mm (W) x 101 mm (H) x 38 mm (D) |

| Weight | 0.6 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5%–95% non-condensing |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Certifications | CE, UL, CSA |

IPMC712

Main Features and Advantages:Motorola IPMC712

High-Performance Processing: The Motorola IPMC712’s PowerPC 750GX processor and 512 MB DDR SDRAM enable rapid execution of control logic and real-time data processing, making it suitable for complex automation tasks. This performance is critical in applications such as high-speed packaging lines or real-time quality control systems, where split-second decisions are essential.

Rugged Industrial Design: Built to withstand extreme temperatures (-40°C to +70°C), vibration, and shock, the IPMC712 is ideal for harsh environments like oil refineries, steel mills, or outdoor transportation hubs. Its fanless design eliminates moving parts, reducing the risk of mechanical failure and minimizing maintenance needs.

Flexible Connectivity: With dual Gigabit Ethernet ports, serial interfaces, and USB support, the controller offers versatile connectivity options for integrating with sensors, actuators, and higher-level systems. This flexibility allows it to serve as a gateway between legacy equipment and modern industrial networks, facilitating retrofits and system upgrades.

Real-Time Operating System Compatibility: The IPMC712 supports popular RTOS platforms, ensuring deterministic performance and reliable task scheduling. This is crucial for applications requiring precise timing, such as robotics coordination or conveyor belt synchronization in manufacturing facilities.

Compact and Easy Installation: Measuring just 146 mm in width, the controller fits into space-constrained enclosures, while its DIN rail mounting simplifies installation alongside other industrial components. This design efficiency reduces setup time and costs, making it a preferred choice for both new installations and retrofitted systems.

IPMC712

Application Areas:Motorola IPMC712

The Motorola IPMC712 is deployed across diverse industries to address critical automation needs:

-

Manufacturing and Robotics:

- Controls robotic arms, CNC machines, and assembly lines, ensuring precise motion control and process synchronization.

- Manages real-time data from sensors to optimize production flow, reduce waste, and enhance quality control.

-

Energy and Utilities:

- Monitors and controls power generation systems, such as wind turbines or solar inverters, enabling remote management and predictive maintenance.

- Oversees water treatment plants by managing pump stations, valve actuators, and quality sensors to ensure regulatory compliance.

-

Transportation and Logistics:

- Powers traffic control systems, railway signaling, and baggage handling systems, requiring reliable performance in dynamic environments.

- Integrates with GPS and telemetry systems for real-time tracking and management of fleets or cargo.

-

Oil and Gas:

- Operates in offshore platforms and refineries to monitor pressure, temperature, and flow rates in hazardous areas.

- Supports remote terminal units (RTUs) for pipeline monitoring, ensuring safety and efficiency in upstream and downstream operations.

Related Products:Motorola IPMC712

- Motorola IPMC714: An upgraded variant with increased memory (1 GB DDR SDRAM) and storage (512 MB Flash), suitable for data-intensive applications like machine vision or edge computing.

- Motorola MVME6100: A modular single-board computer (SBC) from the same series, offering PCI/104 expansion for advanced I/O configurations.

- Motorola IPMC722: Features additional serial ports and isolated I/O channels, ideal for legacy system integration or applications requiring extensive field device connectivity.

- Motorola XMC4200: A high-performance embedded controller with PCI Express expansion, designed for next-generation automation systems.

- Motorola FC6000: A fanless industrial computer with similar ruggedness, suited for HMI or supervisory control roles in conjunction with the IPMC712.

IPMC712

Installation and Maintenance:Motorola IPMC712

Pre-installation Preparation:

Before installing the Motorola IPMC712, ensure the following:

Before installing the Motorola IPMC712, ensure the following:

- Verify the power supply voltage (18–36 VDC) and use a filtered power source to prevent electrical noise interference.

- Clean the installation area to remove dust or debris that could affect heat dissipation.

- Secure the controller to a DIN rail using the provided mounting brackets, ensuring proper alignment with adjacent components.

Maintenance Recommendations:

- Regularly inspect the controller’s LED indicators to monitor power status, communication activity, and error messages.

- Clean the exterior with a dry, lint-free cloth to maintain airflow in fanless operations.

- Update firmware periodically using Motorola’s dedicated software tools to access bug fixes and new features.

- In high-vibration environments, check all connections (power, Ethernet, serial) for tightness and re-tighten as needed to prevent loose contacts.

IPMC712

Product Warranty:Motorola IPMC712

Our company offers a one-year quality warranty for the Motorola IPMC712, covering hardware defects arising from non-human causes. During the warranty period, we will replace any defective unit promptly to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid access to scarce parts, supporting uninterrupted operation of industrial systems. We stand behind the reliability of our products and are committed to delivering exceptional service to meet your automation needs.

Note: This description is based on comprehensive technical research and industry applications. For detailed specifications, refer to Motorola’s official documentation or contact our technical support team.

Hirschmann MM3-2FXM2-2TX1 probe

Hirschmann MM20-Z6Z6Z6Z6SAHH Tachometer sensor

TRICONEX DO2401 7400209-030 rack

TRICONEX AI3351 Digital 24VDC output module

ABB UFC721BE101 Safety system

TRICONEX RO3451 FIM card

ENTERASYS A4H124-24FX Communication input interface component

ABB 07KT98 GJR5253100R0278 Servo motor,

ABB 07KT97 GJR5253000R4270 Industrial keyboard

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: