Description

K-Tron KCM-2 Product Specification

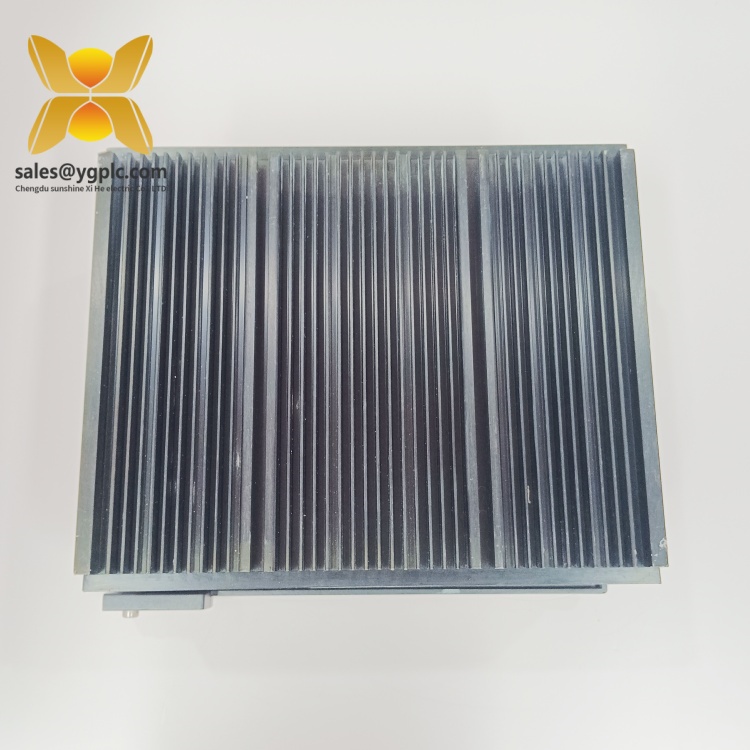

Product Overview:K-Tron KCM-2

The K-Tron KCM-2 is a high-precision process control module designed for industrial material handling and weighing systems. Manufactured by K-Tron, a global leader in bulk solids processing solutions, the KCM-2 belongs to the company’s advanced Process Control Series, renowned for its accuracy, reliability, and seamless integration with material handling equipment. This module serves as the core controller for gravimetric and volumetric feeding systems, enabling real-time monitoring and adjustment of material flow rates in industries such as food and beverage, chemical, pharmaceutical, and plastics manufacturing.

As a compact yet powerful controller, the K-Tron KCM-2 processes signals from load cells, speed sensors, and other field devices to calculate material throughput and maintain precise control over feeding operations. It supports both standalone operation and integration into distributed control systems (DCS) via industrial communication protocols like Modbus TCP and EtherNet/IP. With its user-friendly interface and configurable control algorithms, the KCM-2 allows engineers to optimize feeding processes for different materials, from free-flowing powders to sticky slurries, ensuring minimal waste and maximum production efficiency.

In automation systems, the K-Tron KCM-2 acts as a critical link between weighing hardware and higher-level control systems, providing real-time data for inventory management, quality control, and process optimization. Its rugged design (IP65-rated enclosure) and wide operating temperature range (-20°C to +60°C) make it suitable for harsh industrial environments, while its modular architecture simplifies maintenance and upgrades. By combining high-speed processing with advanced diagnostic capabilities, the KCM-2 helps industries achieve compliance with regulatory standards (e.g., FDA, GMP) and reduce operational downtime.

Technical Specifications:K-Tron KCM-2

| Parameter Name | Parameter Value |

|---|---|

| Product Model | K-Tron KCM-2 |

| Manufacturer | K-Tron (a brand of Thermo Fisher Scientific) |

| Product Type | Process Control Module (Gravimetric/Volumetric Feeding) |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 178 mm (W) × 102 mm (H) × 254 mm (D) (19-inch rack-mountable) |

| Weight | 1.5 kg |

| Communication Protocols | Modbus TCP, EtherNet/IP, RS-485 (Modbus RTU) |

| Input Channels | 4 analog inputs (0–10 VDC/4–20 mA), 8 digital inputs |

| Output Channels | 2 analog outputs (0–10 VDC/4–20 mA), 6 digital outputs (relay/solid-state) |

| Control Algorithms | PID control, adaptive filtering, loss-in-weight (LIW) compensation |

| Operating Temperature | -20°C to +60°C |

| Environmental Rating | IP65 (dust/water-resistant enclosure) |

K-Tron KCM-2

Main Features and Advantages:K-Tron KCM-2

Precision Control for Material Handling: The K-Tron KCM-2 utilizes advanced digital signal processing to achieve weighing accuracy within ±0.1% of full scale, critical for industries requiring precise batch control or continuous feeding. Its loss-in-weight (LIW) and gain-in-weight (GIW) algorithms dynamically adjust feeder speed to maintain target flow rates, even during material transitions or system disturbances.

Flexible System Integration: With support for multiple industrial communication protocols, the KCM-2 easily integrates with PLCs, HMIs, and DCS systems from manufacturers like Rockwell Automation, Siemens, and ABB. This versatility allows it to serve as a standalone controller or part of a larger automated network, reducing the need for custom programming.

User-Centric Design: The module features a color LCD display and intuitive keypad for on-site configuration and diagnostics, eliminating the need for external software during basic setup. Advanced users can leverage K-Tron’s ProcessMaster software for remote monitoring, recipe management, and firmware updates, enhancing operational efficiency.

Rugged Industrial Performance: Built with a metal enclosure and conformal-coated PCBs, the KCM-2 withstands high humidity, dust, and vibrations typical of manufacturing environments. Its wide temperature range and EMC compliance (EN 61326-1) ensure reliable operation in both indoor and outdoor installations, from factory floors to outdoor bulk storage facilities.

Scalable and Modular: The KCM-2 supports expandable I/O modules, allowing users to add additional analog/digital channels as needed for complex systems. This scalability makes it suitable for small-scale single-feeder setups as well as large multi-feeder batching systems, providing a cost-effective solution across various application sizes.

K-Tron KCM-2

Application Areas:K-Tron KCM-2

The K-Tron KCM-2 is widely applied in industries where precise material handling and process control are essential:

-

Food and Beverage:

- Controls ingredient feeding in mixing and blending systems for products like snacks, powders, and liquids.

- Ensures compliance with hygiene standards by supporting quick-release mechanisms and corrosion-resistant materials in contact parts.

-

Chemical and Petrochemical:

- Manages the feeding of polymers, additives, and catalysts in extrusion and polymerization processes.

- Integrates with safety systems to trigger alarms or shutdowns in case of material flow anomalies.

-

Pharmaceutical:

- Provides traceability and accuracy in the dosing of active pharmaceutical ingredients (APIs) for tablet pressing and capsule filling.

- Meets GMP requirements with audit trails and secure user access controls.

-

Plastics and Polymers:

- Optimizes the feeding of resins, fillers, and colorants in injection molding and compounding lines.

- Reduces material waste by maintaining tight control over melt flow rates and batch consistency.

-

Mining and Minerals:

- Controls the feeding of ores and concentrates in crushing and screening operations.

- withstands heavy dust and vibration in open-pit mining or processing plants.

K-Tron KCM-2

Related Products:K-Tron KCM-2

- K-Tron KCM-3: An upgraded version of the KCM-2 with enhanced processing power and additional I/O channels, suitable for large-scale multi-feeder systems.

- K-Tron KCM-2B: A budget-friendly variant with basic control features, ideal for simple volumetric feeding applications.

- K-Tron S2M Series Load Cells: High-precision load cells designed for use with the KCM-2, offering reliable weight measurement in harsh environments.

- K-Tron 3000 Series Feeders: Gravimetric and volumetric feeders that pair seamlessly with the KCM-2 for integrated material handling solutions.

- K-Tron ProcessMaster Software: A supervisory control software that enhances the KCM-2’s capabilities with advanced data logging, remote access, and recipe management.

Installation and Maintenance:K-Tron KCM-2

Pre-installation Preparation:

Before installing the K-Tron KCM-2, ensure the following:

Before installing the K-Tron KCM-2, ensure the following:

- Verify the power supply voltage (24 VDC) and ground the module properly to prevent electrical noise interference.

- Mount the module in a 19-inch rack with adequate ventilation to maintain optimal operating temperature.

- Connect load cells and sensors using shielded cables to minimize EMI/RFI interference, following K-Tron’s wiring diagrams.

Maintenance Recommendations:

- Regular Calibration: Perform quarterly calibration using known weights to ensure measurement accuracy. The KCM-2’s built-in calibration wizard simplifies this process.

- Software Updates: Periodically check for firmware updates via ProcessMaster software to access new features and security patches.

- Environmental Checks: Inspect the enclosure for dust or debris buildup monthly, especially in dusty environments, and clean using a dry cloth or compressed air.

- Component Testing: Test I/O channels annually using a multimeter or signal generator to ensure proper functionality. Replace faulty relays or connectors promptly.

K-Tron KCM-2

Product Warranty:K-Tron KCM-2

Our company offers a one-year quality warranty for the K-Tron KCM-2, covering all non-human-induced hardware defects. During the warranty period, any module experiencing signal processing errors, power supply failures, or display malfunctions will be replaced or repaired at no cost. For discontinued models or urgent repair needs, our global supply chain network ensures fast turnaround times, leveraging our extensive inventory of industrial control spare parts. We also provide post-warranty technical support and maintenance services to help customers maximize the lifespan and performance of their KCM-2 modules.

Note: This product description is based on technical data from K-Tron’s official specifications and industry applications. For detailed operational guidelines or customization options, contact our technical support team or refer to the K-Tron KCM-2 user manual.

EMERSON A6410 9199-00005 Servo valve

EMERSON A6110 9199-00001 Analog input

HONEYWELL EG1033AA EG1033AA01 261A1812P002 Control cabinet node unit

ABB PM864AK01 3BSE018161R1 Gas turbine card

ABB SCYC51010 58052515G DO module

Siemens 6DD2920-0AM0 AI card

Siemens 6DD2920-0BB0 Pulse encoder

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: