Description

GE IS410STAIS2A Product Specification

Product Overview

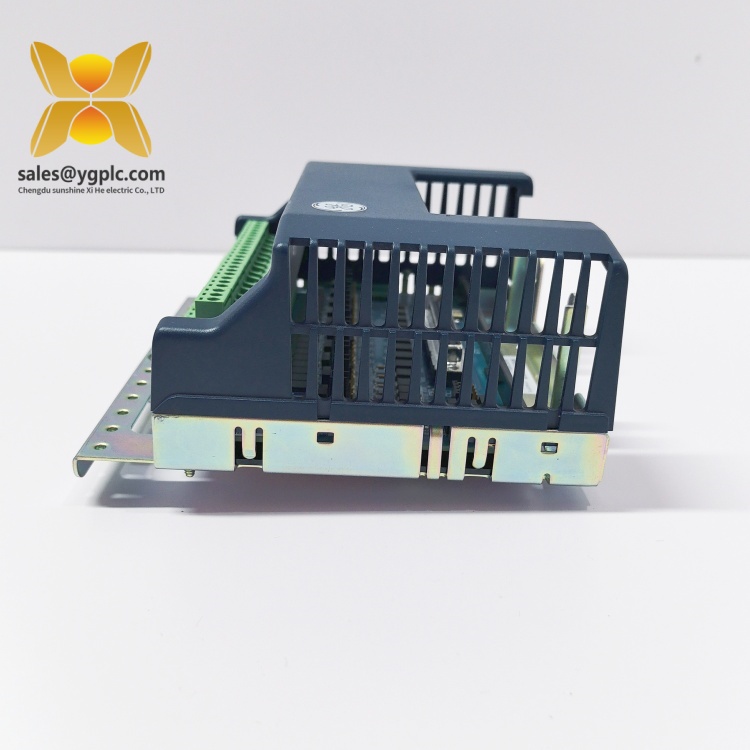

The GE IS410STAIS2A is a high-performance simplex analog I/O terminal board engineered for GE’s Mark VIe Speedtronic Turbine Control System, serving as a critical interface for converting analog signals from field devices into digital data for industrial automation. Designed to handle 10 analog inputs (AI) and 2 analog outputs (AO), this module enables precise monitoring and control of temperature, pressure, flow, and other process variables in gas turbines, steam turbines, and rotating machinery across power generation, oil and gas, and heavy manufacturing.

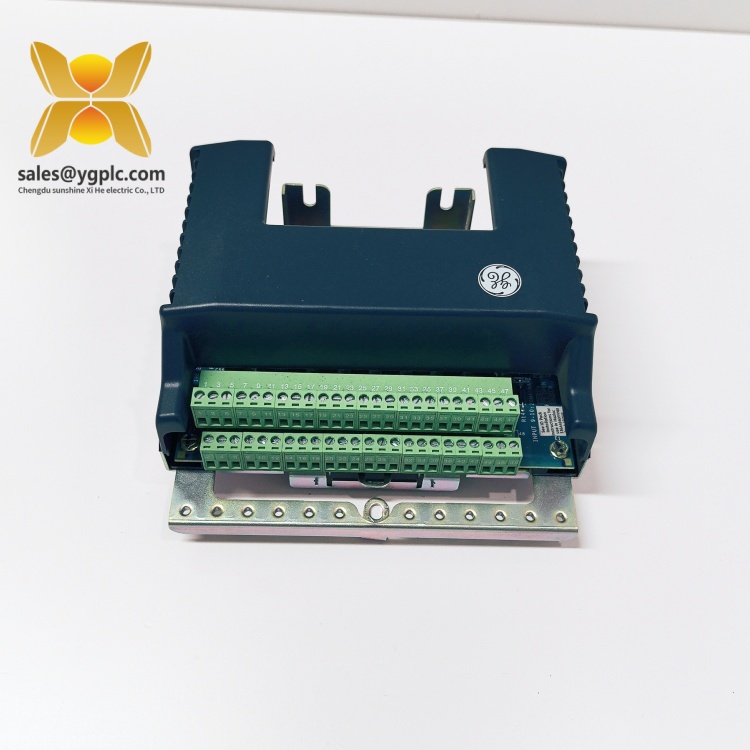

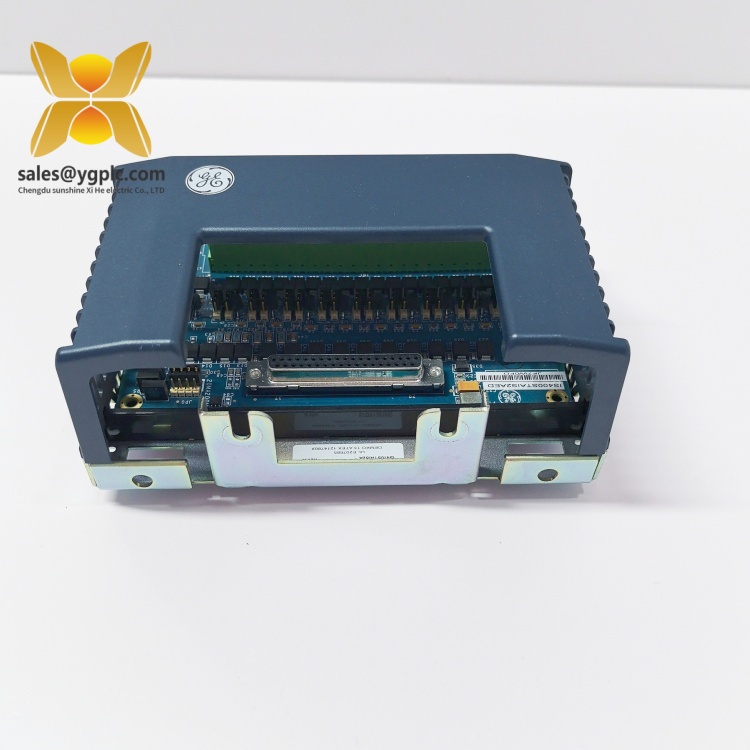

As part of the Mark VIe distributed control architecture, the GE IS410STAIS2A supports a wide range of analog signal types, including 2-wire, 3-wire, 4-wire, and externally powered transmitters, ensuring compatibility with diverse sensor and actuator systems 24. Its 0–20 mA analog output capability allows seamless integration with control valves and variable-frequency drives (VFDs), while high-density Euro-style box terminal blocks simplify wiring and maintenance. An on-board ID chip automatically identifies the module to the system pack, streamlining diagnostics and reducing configuration errors 24.

In automation systems, the GE IS410STAIS2A acts as the analog backbone for closed-loop control loops, translating sensor inputs into actionable commands for turbine governors, compressor anti-surge systems, and generator excitation modules. Its compact 16 cm × 10 cm × 4 cm (6.3″ × 3.9″ × 1.6″) DIN rail-mountable design optimizes space in control cabinets, while the rugged IP20-rated enclosure with triple-layer conformal coating ensures reliable operation in harsh environments (-30°C to +65°C) with high vibration, humidity, and chemical exposure 24.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS410STAIS2A |

| Manufacturer | General Electric (GE) |

| Product Type | Simplex Analog I/O Terminal Board |

| Series | Mark VIe Speedtronic Turbine Control System |

| Analog Inputs | 10 channels (2/3/4-wire or externally powered transmitters) |

| Analog Outputs | 2 channels (0–20 mA) |

| Physical Dimensions | 16 cm (H) × 10 cm (W) × 4 cm (D) 2 |

| Weight | 0.5 kg 2 |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Terminal Type | Euro-style box terminal blocks |

| On-Board Features | ID chip for system diagnostics |

| Mounting Type | DIN rail mountable |

| Certifications | CE, UL 508, Class I Division 2 (with compatible enclosures) |

Main Features and Advantages

Versatile Signal Handling:

The GE IS410STAIS2A supports a broad spectrum of analog signal types, accommodating 2-wire transmitters for cost-effective sensor integration and 4-wire configurations for high-accuracy measurements in critical processes like turbine temperature monitoring. Its 0–20 mA analog outputs enable direct control of proportional valves and actuators, eliminating the need for intermediate signal converters 24.

Space-Saving Design:

With dimensions of 16 cm × 10 cm × 4 cm and a weight of just 0.5 kg, the GE IS410STAIS2A optimizes cabinet space while delivering robust performance. The DIN rail-mountable form factor allows easy installation alongside other Mark VIe modules like IS410JPDHG1A (power supply) and IS230TCISH6C (discrete I/O), creating a compact yet powerful control system 24.

Enhanced Diagnostics:

An integrated ID chip automatically communicates the module’s identity and status to the Mark VIe system pack, simplifying troubleshooting and reducing downtime. This feature enables real-time monitoring of signal integrity and terminal block connections, ensuring rapid identification of faults in high-stakes applications like turbine protection systems 24.

Rugged Industrial Reliability:

The module’s triple-layer conformal coating protects against dust, moisture, and chemical contaminants, while its vibration resistance (10–2000 Hz, 10 G rms) ensures stable operation in high-vibration environments like turbine halls. A wide operating temperature range (-30°C to +65°C) adapts to extreme climates, from arctic LNG plants to desert power stations 24.

Seamless Integration:

Designed for compatibility with the IS420YAICS1B I/O pack, the GE IS410STAIS2A ensures seamless data transfer between field devices and the Mark VIe controller. Its Euro-style terminal blocks support easy wiring changes, while the hot-swappable design allows module replacement without powering down the system, minimizing maintenance downtime 24.

Application Areas

Power Generation:

- Monitors turbine inlet temperatures via 4-wire RTD sensors, adjusting fuel flow rates to optimize combustion efficiency.

- Controls steam turbine governor valves using 0–20 mA analog outputs, maintaining grid frequency during load fluctuations.

- Measures generator winding temperatures to trigger cooling system activation, preventing overheating.

Oil and Gas:

- Manages pipeline pressure sensors in offshore platforms, using analog inputs to adjust compressor speeds and prevent surge conditions.

- Actuates emergency shutdown (ESD) valves via analog outputs in response to high-pressure alarms, ensuring safety in hazardous environments.

- Monitors hydrocarbon levels in refinery distillation columns, providing feedback to control reflux rates and product quality.

Heavy Manufacturing:

- Regulates oven temperatures in steel mills using 2-wire thermocouple inputs, ensuring consistent material processing.

- Controls robotic arm positioning in automotive plants via analog outputs, synchronizing motion with assembly line conveyors.

- Measures conveyor belt tension using load cells, adjusting motor speeds to prevent belt slippage or breakage

Renewable Energy:

- Monitors solar panel efficiency using irradiance sensors, optimizing inverter settings to maximize energy production.

- Controls wind turbine pitch systems via analog outputs, adjusting blade angles to maintain optimal power capture in varying wind conditions.

- Measures battery state-of-charge in energy storage systems, balancing load distribution to extend battery life.

Related Products

- GE IS420YAICS1B: I/O pack that interfaces with GE IS410STAIS2A, providing signal conditioning and communication with the Mark VIe controller.

- GE IS410JPDHG1A: Power supply module that delivers stable 24 VDC to GE IS410STAIS2A, ensuring reliable analog signal processing 4.

- GE IS230TCISH6C: Discrete I/O terminal board that works alongside GE IS410STAIS2Ato manage digital and analog signals in hybrid control systems.

- GE IS400TCASH1AFD: Thermocouple input module that complements GE IS410STAIS2Afor temperature monitoring in turbine systems.

- GE IS220VCMIH1A: Communication module that bridges GE IS410STAIS2Awith the Mark VIe controller, enabling remote configuration and diagnostics.

- GE IS220PPROS1B: Redundant power supply module that ensures uninterrupted operation of GE IS410STAIS2Ain mission-critical applications.

Installation and Maintenance

Pre-installation Preparation:

Before installing GE IS410STAIS2A, verify the control cabinet’s ambient temperature (-30°C to +65°C) and humidity (5–95% non-condensing) meet specifications. Use an ESD wrist strap during handling to prevent electrostatic damage. Mount the module on a 35 mm DIN rail with 20 mm clearance for airflow, securing it with M4 screws (torque: 0.5–0.7 N·m). Connect Euro-style terminal blocks to field devices, ensuring proper wire gauges (22–16 AWG) and polarity. Link the module to the IS420YAICS1B I/O pack using shielded cables to minimize electromagnetic interference 24.

Maintenance Recommendations:

Perform monthly visual inspections to confirm front-panel LEDs (Power, Fault) indicate normal operation. Clean dust from terminal blocks and ventilation slots using compressed air to maintain signal integrity. Quarterly, use a multimeter to verify analog output accuracy (0–20 mA ±1%) and check terminal connections for corrosion. Annually, update firmware via GE’s Proficy software to address compatibility issues. Replace the module every 7–10 years or if signal drift exceeds 2% of full scale, as aging components may affect measurement precision.

Product Warranty

Our company offers a one-year quality warranty for the GE IS410STAIS2A, covering hardware malfunctions not caused by human factors. During the warranty period, if the module exhibits signal inaccuracies, communication failures, or physical defects, we will provide replacement services. As a leading import-export distributor with 17 years of experience, we maintain large inventories of industrial control parts, including hard-to-find models like GE IS410STAIS2A, to meet urgent procurement needs. Our global supply chain network ensures rapid fulfillment of scarce spare parts, supporting the continuous operation of your industrial systems. Whether for routine maintenance or emergency repairs, we are committed to delivering reliable support to minimize downtime.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: