Description

GE IC694ALG223-DB Series 90-40 Analog Current Input Module

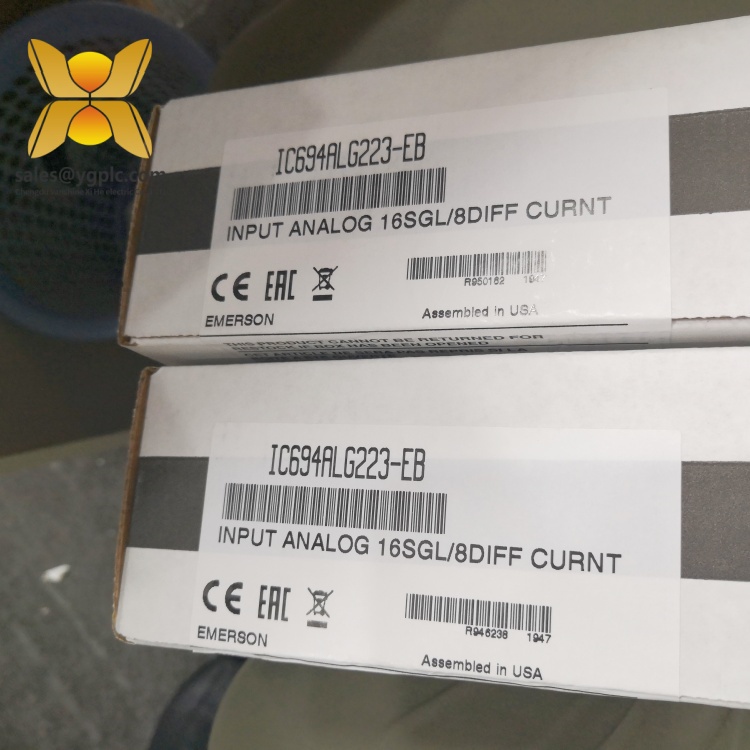

Product Overview

The GE IC694ALG223-DB is a high-precision analog current input module designed for GE’s Series 90-40 PLC system, specializing in converting analog signals into digital data for industrial automation applications. With 16 single-ended channels, this module supports three configurable input ranges: 4–20 mA, 0–20 mA, and 4–20 mA Enhanced. The Enhanced range enables open-wire fault detection by identifying current drops below 4 mA, critical for maintaining system reliability in process control environments such as chemical plants or oil refineries.

Engineered for flexibility, the IC694ALG223-DB allows per-channel configuration of alarm limits (low/high) and reference addresses, ensuring precise monitoring of variables like pressure, flow, or temperature. Its 12-bit resolution and 13 ms update rate (all channels) provide real-time data acquisition, while optical isolation (250 VAC continuous) safeguards against electromagnetic interference and ground loops. The module draws 120 mA from the 5 VDC backplane and 65 mA from an external 24 VDC supply, making it compatible with GE’s IC694PWR331A power module for stable operation.

Integrated with the Series 90-40 ecosystem, the IC694ALG223-DB fits seamlessly into racks like the IC694CHS392, supporting hot-swappable installation for maintenance without system downtime. Its compact design (30 cm × 20 cm × 20 cm) and lightweight construction (1.0 kg) optimize space in control cabinets, while industrial-grade materials ensure durability in temperatures ranging from -10°C to 55°C.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC694ALG223-DB |

| Manufacturer | GE |

| Product Type | 16-Channel Analog Current Input Module |

| Series | Series 90-40 |

| Input Ranges | 4–20 mA, 0–20 mA, 4–20 mA Enhanced (open-wire detection) |

| Resolution | 12 bits |

| Update Rate | 13 ms (all channels) |

| Accuracy | ±0.25% of full scale @ 25°C; ±0.5% over -10°C to 55°C |

| Physical Dimensions | 30 cm (L) × 20 cm (W) × 20 cm (D) |

| Weight | 1.0 kg |

| Isolation | 250 VAC continuous; 1500 VAC for 1 minute |

| Power Consumption | 120 mA @ 5 VDC (backplane); 65 mA @ 24 VDC (external) |

| Compatibility | Series 90-40 racks (e.g., IC694CHS392) |

| Operating Temperature | -10°C to 55°C |

| Humidity Resistance | 5–95% non-condensing |

| Country of Origin | United States |

IC694ALG223-DB

Related Products

- GE IC694CPU325: A high-performance Series 90-40 CPU module that processes data from the IC694ALG223-DB, managing control logic and system coordination.

- GE IC694CHS392: A 10-slot rack housing the IC694ALG223-DB and other modules, providing structural support and backplane connectivity.

- GE IC694PWR331A: A power supply module delivering 5 VDC and 24 VDC to the IC694ALG223-DB, ensuring stable operation.

- GE IC694ALG220: A 4-channel analog voltage input module for applications requiring mixed signal types, complementing the IC694ALG223-DB in complex systems.

- GE IC694BEM331: A Genius Bus communication module that enables real-time data exchange between the IC694ALG223-DB and other networked devices.

Main features and advantages

high-precision signal conversion: The IC694ALG223-DB offers 12-bit resolution and factory calibration (4 μA/count for 4–20 mA; 5 μA/count for other ranges), ensuring accurate measurement of critical process variables. Its ±0.25% full-scale accuracy at 25°C minimizes errors in demanding environments like pharmaceutical production.

open-wire fault detection: The 4–20 mA Enhanced range identifies current drops below 4 mA, alerting operators to wiring issues before they escalate. This feature is vital in industries like water treatment, where sensor failures could disrupt compliance with environmental standards.

flexible configuration: Each channel can be independently programmed for input range, alarm thresholds, and data addressing, allowing tailored monitoring for diverse applications. For example, a single IC694ALG223-DB can simultaneously track flow rates (4–20 mA) and tank levels (0–20 mA) in a manufacturing plant.

rugged industrial design: Withstands extreme temperatures (-10°C to 55°C) and harsh conditions, including dust and vibrations. Its optical isolation and low-pass filter (19 Hz) reduce noise interference, ensuring reliable performance in noisy environments like power generation facilities.

hot-swappable operation: Technicians can replace the IC694ALG223-DB without powering down the PLC system, minimizing downtime during maintenance or system expansions. This is critical in 24/7 operations, such as automotive assembly lines.

Installation and maintenance

Pre-installation preparations: Power off the Series 90-40 rack (e.g., IC694CHS392) and ensure the target slot is clean. Align the IC694ALG223-DB with the slot, pressing firmly until latched. Verify proper grounding and use twisted/shielded cables to reduce EMI. Connect the external 24 VDC supply (20–30 VDC) and backplane power, then configure channels via GE Proficy software or handheld programmers.

Maintenance suggestions: Conduct quarterly inspections to check for loose connections or physical damage. Monitor LED indicators (Module OK, User Supply) for status—steady green indicates normal operation, while rapid flashing signals configuration issues. Clean dust from vents using compressed air. If replacing the module, follow hot-swap procedures and recalibrate channels if exposed to extreme temperatures.

Application Fields

The GE IC694ALG223-DB excels in industries requiring precise analog signal monitoring:

- Manufacturing: Monitors conveyor belt speeds, robotic arm positioning, and material flow in automotive or food processing plants. Its open-wire detection prevents production delays caused by sensor malfunctions.

- Energy: Tracks pressure and temperature in oil refineries or gas pipelines, ensuring safe operation and regulatory compliance. Works with the IC694CPU325 to automate valve adjustments based on real-time data.

- Water treatment: Measures pH levels, chlorine concentration, and pump performance in wastewater treatment facilities. The module’s isolation features protect against corrosive environments.

- Power generation: Supports turbine control systems by monitoring steam pressure and generator load. Its high update rate enables responsive adjustments to maintain grid stability.

Product Guarantee

Our company offers a one-year quality warranty service for the IC694ALG223-DB, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

Our company is a leading enterprise in the industrial control industry, established in 2007, has been 17 years. The company type is an import and export trade distribution company, mainly selling major brands of industrial control parts, there are many unpopular discontinued models, with a large stock. Our company has the advantage of supply channels, a large number of spot, to meet the needs of customers anxious to find spare parts. Our main business includes the distribution and trade of PLC modules, DCS cards, ESD system cards, vibration monitoring system cards, turbine control system modules, gas generator spare parts, instruments and other products.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: