Description

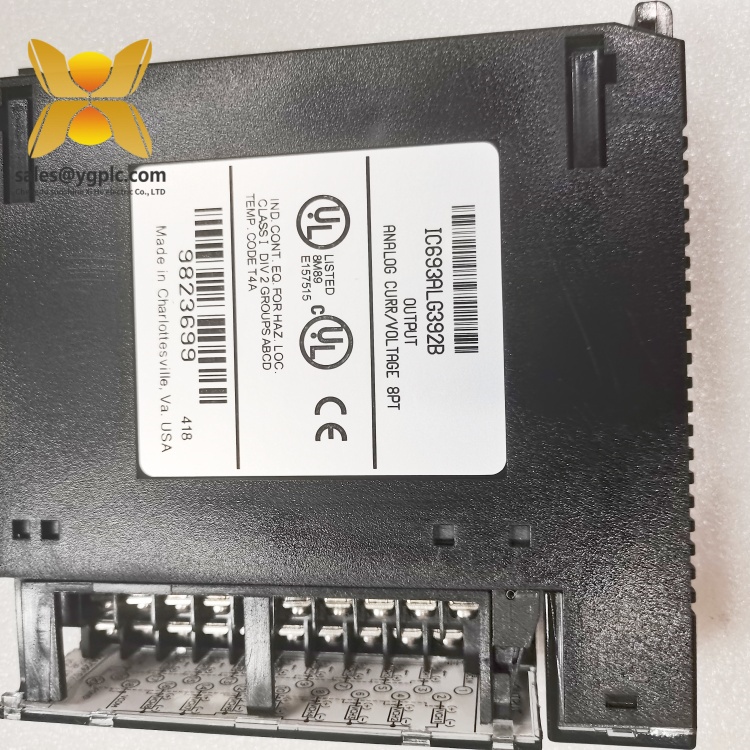

Product Overview: GE IC693ALG392-BD 8-Channel Analog Current/Voltage Output Module

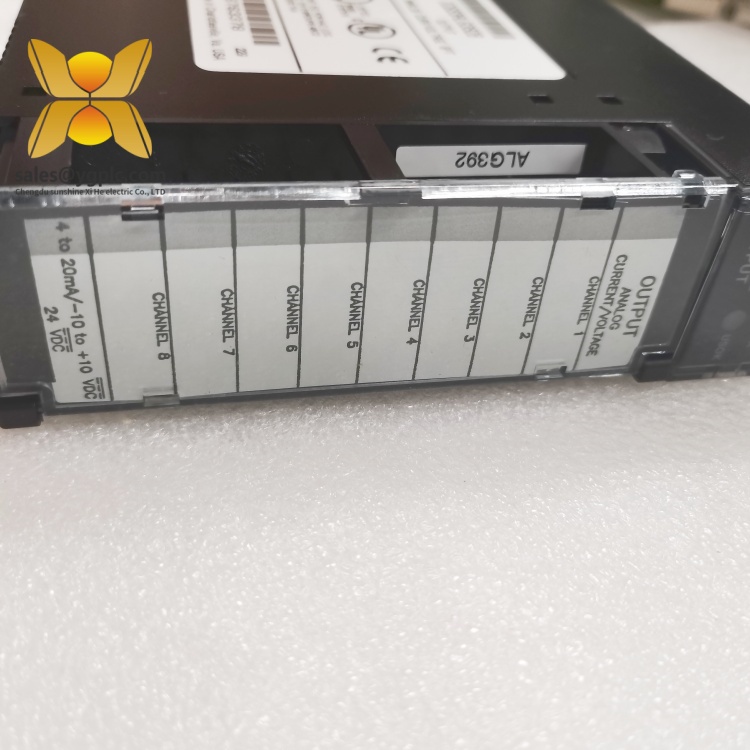

The GE IC693ALG392-BD is a high-performance 8-channel analog output module engineered for industrial automation systems, specifically designed for integration with the GE Series 90-30 PLC platform. As a critical component in process control and monitoring applications, this module converts digital signals from the PLC into precise analog voltage or current outputs, enabling seamless control of actuators, valves, and other analog devices. With eight independently configurable channels, the IC693ALG392-BD supports voltage ranges of 0–10 V (unipolar) and –10 to +10 V (bipolar), as well as current ranges of 0–20 mA and 4–20 mA. Its 15-bit or 16-bit resolution (depending on the selected range) ensures exceptional accuracy, making it ideal for applications requiring fine-grained control in chemical processing, power generation, and robotics.

Part of GE’s robust Series 90-30 lineup, the IC693ALG392-BD is built to withstand harsh industrial environments, with a rugged design that ensures reliable operation across a temperature range of 0°C to 60°C (32°F to 140°F) and high noise immunity. The module’s isolated channels and 500 VDC isolation between channels and the backplane protect against electrical interference, ensuring signal integrity even in high-vibration or electrically noisy settings. Its compact form factor (31.24 mm x 35 mm x 87.63 mm) and low power consumption (110 mA at 5 VDC from the PLC backplane, 315 mA at 24 VDC from an external supply) make it suitable for space-constrained installations while maintaining energy efficiency.

The GE IC693ALG392-BD is a cornerstone of industrial automation, providing real-time control for process optimization, quality assurance, and safety-critical operations. Its compatibility with GE’s Series 90-30 PLCs ensures seamless integration with existing infrastructure, making it a cost-effective solution for retrofitting or expanding automation systems. Whether deployed in standalone applications or integrated into larger distributed control systems (DCS), the IC693ALG392-BD delivers unmatched performance and versatility, solidifying its position as a preferred choice for industrial engineers worldwide.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | GE |

| Product Type | 8-Channel Analog Current/Voltage Output Module |

| Output Voltage Ranges | 0–10 V (unipolar), –10 to +10 V (bipolar) |

| Output Current Ranges | 0–20 mA, 4–20 mA |

| Resolution | 15 or 16 bits (depending on output range) |

| Absolute Accuracy | ±0.1% of full scale |

| Update Rate | 8 ms (all channels) |

| Isolation | 500 VDC (channels to backplane) |

| Power Consumption | 110 mA @ 5 VDC (backplane), 315 mA @ 24 VDC (external supply) |

| Physical Dimensions | 31.24 mm x 35 mm x 87.63 mm (1.23 x 1.38 x 3.45 inches) |

| Weight | 0.13 kg (0.29 lbs) |

| Place of Origin | USA |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| External Supply Voltage | 20–30 VDC |

| Output Load Capacitance | 2000 pF maximum |

Main Features and Advantages

The GE IC693ALG392-BD stands out for its advanced technical capabilities and user-centric design. Its 8-channel configuration allows simultaneous control of multiple devices, reducing the need for additional modules and simplifying system architecture. The module’s configurable output ranges (voltage/current) and resolution (15/16 bits) offer flexibility for diverse applications, from precise pressure regulation in hydraulic systems to temperature control in industrial ovens.

The GE IC693ALG392-BD stands out for its advanced technical capabilities and user-centric design. Its 8-channel configuration allows simultaneous control of multiple devices, reducing the need for additional modules and simplifying system architecture. The module’s configurable output ranges (voltage/current) and resolution (15/16 bits) offer flexibility for diverse applications, from precise pressure regulation in hydraulic systems to temperature control in industrial ovens.

One of its key strengths is its robust fault detection and signal stability. In current modes, the IC693ALG392-BD reports open-wire faults to the PLC, enabling proactive maintenance and minimizing downtime. The module also maintains its last output value or resets to zero during power interruptions, ensuring predictable behavior in critical processes. With >70 dB common-mode rejection at 60 Hz, it effectively mitigates electromagnetic interference, ensuring stable output signals in high-noise environments.

The IC693ALG392-BD is engineered for ease of integration. Its plug-and-play design allows quick installation in GE Series 90-30 racks, and software-based configuration eliminates the need for manual jumpers or switches. Additionally, the module’s compatibility with GE’s programming tools, such as Proficy Machine Edition, ensures seamless integration into existing control systems, reducing engineering effort and costs.

For applications requiring scalability, the IC693ALG392-BD can be paired with other Series 90-30 modules (e.g., analog input modules, communication modules) to create a comprehensive automation solution. Its compact size and low power consumption further enhance its appeal in distributed control systems where space and energy efficiency are critical.

Application Fields

The GE IC693ALG392-BD is widely used across industries where precise analog control is essential. In manufacturing, it regulates motor speed, adjusts valve positions in hydraulic systems, and controls robotic arms, ensuring consistent product quality and production efficiency. In energy production, the module is deployed in power plants to control steam turbine governors and adjust fuel flow rates, optimizing energy output and reducing emissions.

The GE IC693ALG392-BD is widely used across industries where precise analog control is essential. In manufacturing, it regulates motor speed, adjusts valve positions in hydraulic systems, and controls robotic arms, ensuring consistent product quality and production efficiency. In energy production, the module is deployed in power plants to control steam turbine governors and adjust fuel flow rates, optimizing energy output and reducing emissions.

In water treatment facilities, the IC693ALG392-BD controls chemical dosing systems and adjusts pump speeds to maintain optimal water quality. It is also integral to oil and gas operations, where it modulates pressure in pipelines and controls wellhead equipment, contributing to safety and operational reliability.

The module’s versatility extends to HVAC systems, where it regulates heating and cooling systems in commercial buildings, enabling energy-efficient climate control. Its rugged design makes it suitable for outdoor installations in mining and construction, where it withstands extreme temperatures and vibrations.

By providing accurate and timely control signals, the IC693ALG392-BD empowers industries to optimize processes, reduce waste, and enhance safety. Its reliability and compatibility with legacy systems make it a go-to choice for both new installations and retrofitting projects.

Related Products

- GE IC693ALG390: A 2-channel analog voltage output module, suitable for applications requiring fewer channels and simplified configuration.

- GE IC693ALG391: A 2-channel analog current/voltage output module, offering broader flexibility for mixed control applications.

- GE IC693CPU364: A high-performance CPU module for the Series 90-30 platform, providing enhanced processing power for complex control logic.

- GE IC693PWR330: A power supply module compatible with the Series 90-30, ensuring stable voltage delivery to the IC693ALG392-BD.

- GE IC693CHS391: A 10-slot rack for housing Series 90-30 modules, including the IC693ALG392-BD, for centralized control systems.

- GE IC693MDL653: A 24 VDC digital input module, complementing the IC693ALG392-BD in hybrid I/O configurations.

- GE IC693ALG221K: A 4-channel analog input module, enabling closed-loop control when paired with the IC693ALG392-BD.

- GE IC693CMM002: A serial communication module for connecting the IC693ALG392-BD to HMIs or SCADA systems.

Installation and Maintenance

Pre-installation preparations: Before installing the GE IC693ALG392-BD, ensure the PLC rack is powered off and properly grounded. Verify the module’s compatibility with the Series 90-30 platform and check for physical damage. Connect the module to a stable 24 VDC external power source (20–30 VDC) via the terminal block, and ensure the PLC backplane provides 5 VDC. Use twisted, shielded cables for field connections to minimize noise interference, and configure output ranges (voltage/current) using GE’s programming software.

Pre-installation preparations: Before installing the GE IC693ALG392-BD, ensure the PLC rack is powered off and properly grounded. Verify the module’s compatibility with the Series 90-30 platform and check for physical damage. Connect the module to a stable 24 VDC external power source (20–30 VDC) via the terminal block, and ensure the PLC backplane provides 5 VDC. Use twisted, shielded cables for field connections to minimize noise interference, and configure output ranges (voltage/current) using GE’s programming software.

Maintenance suggestions: Regularly inspect the module’s LED indicators to confirm power and signal integrity. Clean dust and debris from the module and its surroundings to prevent overheating. Periodically check the power supply voltage and replace batteries (if applicable) to maintain data retention. For troubleshooting, use GE’s diagnostic tools to monitor channel status and identify potential issues, such as signal drift or output overloads. Replace faulty modules promptly to avoid system downtime, leveraging our company’s extensive inventory of GE IC693ALG392-BD units for quick replacement.

Product Guarantee

Our company offers a one-year quality warranty for the GE IC693ALG392-BD, covering hardware malfunctions not caused by improper use or external factors. During the warranty period, we provide prompt replacement services for defective units. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce spare parts, minimizing downtime and supporting the continuous operation of your industrial systems. We are committed to delivering reliable products and exceptional customer service, backed by 17 years of expertise in industrial control solutions. Contact us today for inquiries or to explore our comprehensive range of automation components.

Our company offers a one-year quality warranty for the GE IC693ALG392-BD, covering hardware malfunctions not caused by improper use or external factors. During the warranty period, we provide prompt replacement services for defective units. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce spare parts, minimizing downtime and supporting the continuous operation of your industrial systems. We are committed to delivering reliable products and exceptional customer service, backed by 17 years of expertise in industrial control solutions. Contact us today for inquiries or to explore our comprehensive range of automation components.

WhatsApp: +86 18859254943 | Email: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: