Description

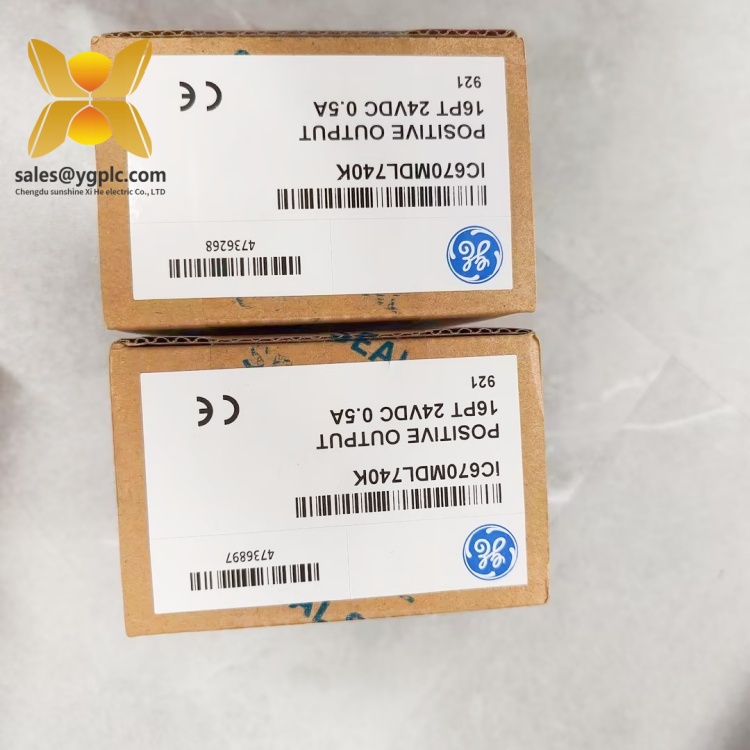

GE IC670MDL740K Genius Field Control Digital Input Module

Product Overview

The GE IC670MDL740K is a high-performance 16-channel digital input module designed for GE’s Genius Field Control and PACSystems RX3i automation platforms, serving as a critical interface for monitoring low-voltage discrete signals in industrial environments. Engineered to convert 24V DC signals from sensors, limit switches, and proximity detectors into digital data, the IC670MDL740K enables real-time monitoring of equipment status in manufacturing, energy, and water treatment sectors.

As part of the IC670 series, the GE IC670MDL740K integrates seamlessly with GE’s Genius Bus architecture, communicating via modules like IC670GBI002 (Bus Interface Unit) to share data with controllers such as IC697CPU780. Its 16 isolated channels (grouped into 4 groups of 4) provide 1500V AC isolation between field inputs and logic circuits, protecting against electrical noise and surges common in factory settings. With a 2-millisecond response time, the module ensures rapid detection of signal changes—critical for time-sensitive applications like emergency stop systems or conveyor jam detection.

The IC670MDL740K operates on 18–30V DC power from the Bus Interface Unit and accepts 24V DC inputs (10–30V DC on-state, 0–5V DC off-state), making it compatible with standard industrial sensors. Its IP65-rated housing resists dust, water splashes, and oil, while a -20°C to 70°C operating range suits harsh environments from cold storage to high-heat production lines. Compliance with UL 508 and IEC 61131-2 underscores its reliability in regulated industries, where precise input monitoring is key to process safety.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IC670MDL740K |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Series | Genius Field Control |

| Input Channels | 16 (4 groups of 4 isolated channels) |

| Input Voltage | 24V DC (10–30V DC on-state; 0–5V DC off-state) |

| Response Time | 2 ms (max) |

| Isolation | 1500V AC (channel-to-logic; group-to-group) |

| Power Supply | 18–30V DC (from Bus Interface Unit) |

| Physical Dimensions | 127mm (L) × 89mm (W) × 64mm (D) |

| Weight | 0.5 kg |

| Operating Temperature | -20°C to 70°C |

| Humidity | 5–95% non-condensing |

| Protection Rating | IP65 (front panel) |

| Communication | Genius Bus via IC670GBI002 |

| Compliance | UL 508, IEC 61131-2, CE |

Main Features and Advantages

High-Density, Low-Voltage Compatibility

The IC670MDL740K’s 16 channels (in a compact 127mm × 89mm form factor) maximize I/O density in control cabinets, reducing space requirements in crowded industrial setups. Its 24V DC input range aligns with standard industrial sensors, eliminating the need for voltage converters and simplifying integration with legacy equipment—ideal for automotive plants using proximity detectors or food processing facilities with washdown-rated sensors.

Rapid Signal Processing

With a 2-ms response time, the module detects signal changes almost instantaneously, ensuring timely alerts for critical events like conveyor jams or emergency stops. This speed is vital in high-throughput environments such as packaging lines, where delays could lead to product damage or downtime.

Robust Isolation and Noise Resistance

1500V AC isolation between channels and logic circuits protects against ground loops and electrical noise from motors or welders, ensuring signal integrity in noisy environments like steel mills. This isolation extends the lifespan of connected components by preventing voltage spikes from reaching sensitive electronics.

Rugged Industrial Design

The IP65-rated front panel resists dust, water splashes, and oil, making the IC670MDL740K suitable for harsh settings—from humid water treatment plants to dusty cement factories. Its -20°C to 70°C operating range ensures reliability in extreme temperatures, eliminating the need for climate-controlled enclosures.

Seamless Integration and Hot-Swap Capability

The module connects directly to the Genius Bus via IC670GBI002, enabling plug-and-play integration with controllers like IC697CPU780. Its hot-swap functionality allows replacement without shutting down the system, minimizing downtime during maintenance—critical for 24/7 operations like power generation facilities.

Application Fields

The GE IC670MDL740K excels in industries requiring reliable low-voltage digital input monitoring:

- Automotive Manufacturing: Tracks robotic arm home positions, part presence sensors, and safety interlocks in assembly lines. Its fast response time ensures rapid shutdowns during collisions, protecting equipment and workers.

- Water Treatment: Monitors valve positions, pump run status, and level switches in filtration systems. The IP65 ratingwithstands humid, chemical-exposed environments, ensuring consistent performance.

- Packaging Automation: Detects bottle presence on conveyors and lid closure sensors in beverage plants. Its high channel density reduces the number of modules needed, lowering cabinet costs.

- Pharmaceutical Production: Monitors cleanroom door interlocks and equipment run signals, where low-voltage compatibility and noise resistance prevent false triggers that could disrupt sterile processes.

Related Products

- GE IC670GBI002: Bus Interface Unit that connects the IC670MDL740Kto the Genius Bus, enabling communication with controllers like IC697CPU780.

- GE IC670MDL750K: 32-channel digital input module, offering double the channels of the IC670MDL740Kfor high-density applications.

- GE IC670MDL241K: 16-channel digital input module for 240V AC signals, serving as a high-voltage alternative to the IC670MDL740K.

- GE IC697CPU780: Genius series controller that processes data from the IC670MDL740K, executing logic to control industrial processes.

- GE IC670CHS002: Terminal block for the IC670MDL740K, simplifying wiring and providing secure connections for sensor cables.

- GE IC670PWR101: 24V DC power supply that pairs with the module, ensuring stable voltage for both the module and connected sensors.

Installation and Maintenance

Pre-installation preparations: Verify the Genius Bus network is powered and the IC670GBI002 is configured. Ensure the 24V DC power supply meets ±10% tolerance. Mount the IC670MDL740K on a DIN rail, aligning with the backplane connector, and secure with retaining clips. Connect sensors to terminal blocks using twisted-pair cables, grounding shields at both ends to reduce noise. Label wires to match the system diagram for easy troubleshooting.

Maintenance suggestions: Conduct monthly visual inspections to check for loose terminals or damaged cables. Clean the front panel with a dry cloth to prevent dust buildup. Quarterly, test each channel by activating connected sensors and verifying LED indicators—dim or unlit LEDs may indicate faulty wiring or sensor issues. If channels fail, replace the module using hot-swap to avoid downtime. Store spare IC670MDL740K units in anti-static bags to protect against electrostatic damage.

Product Guarantee

Our company offers a one-year quality warranty service for the IC670MDL740K, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import and export trade distribution company with 17 years of experience, we maintain a large stock of IC670MDL740K and other Genius series modules, ensuring 48-hour delivery for urgent requirements.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: