Description

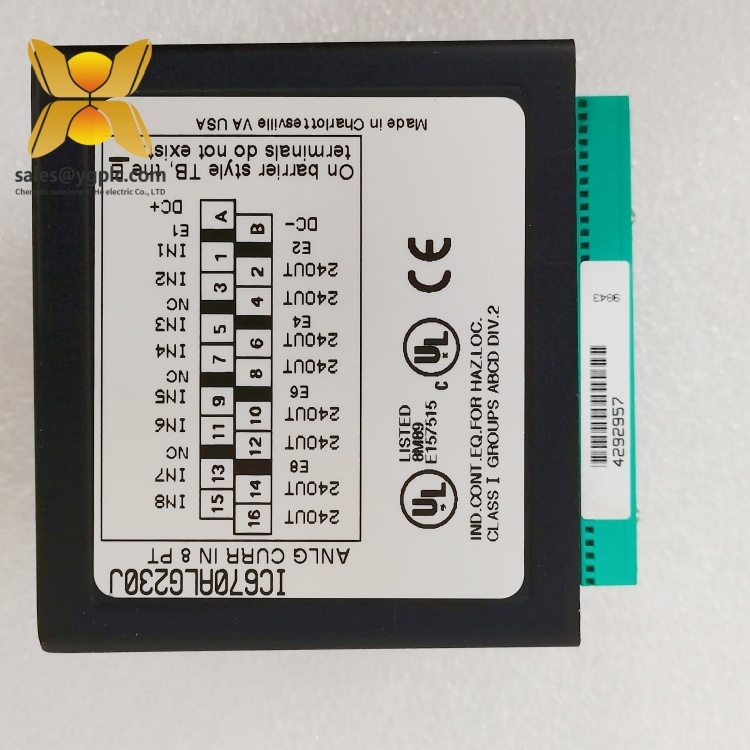

GE IC670ALG230 Genius Field Control Analog Input Module

Product Overview

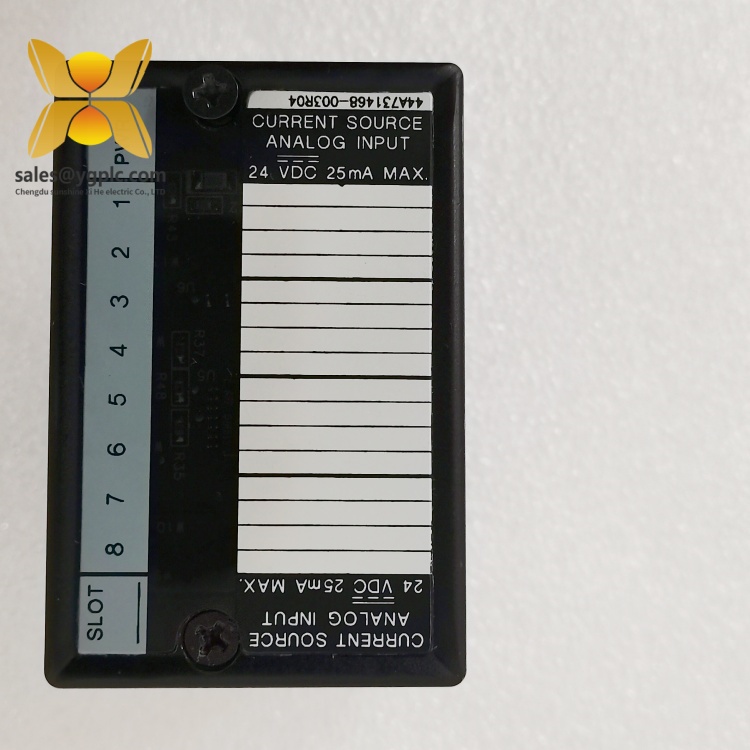

The GE IC670ALG230 is a high-performance 8-channel analog input module designed for GE’s Genius Field Control and PACSystems RX3i automation platforms. Engineered for industrial process control, it converts 4–20 mA or 0–20 mA current signals from sensors (e.g., pressure transmitters, flow meters) into digital data for real-time monitoring and control. As part of the IC670 series, the IC670ALG230 integrates seamlessly with GE’s Genius Bus architecture, enabling reliable data exchange with controllers like IC697CPU780 and other I/O modules such as IC660BBA100 (analog output) and IC660BBD020 (digital I/O).

With 12-bit resolution and 5.0 µA analog precision, the IC670ALG230 ensures accurate measurement in critical applications, including oil refining, power generation, and water treatment. Its 60-microsecond per-channel conversion time supports high-speed data acquisition, while the single-ended grouped input configuration simplifies wiring in distributed systems. The module operates on 18–30 V DC power and features 1500 V AC isolation between channels and ground, ensuring robustness in electrically noisy environments.

Compliant with UL 508 and IEC 61131-2 standards, the IC670ALG230 is certified for use in safety-critical industries. Its IP65-rated housing resists dust, water splashes, and oil, making it suitable for harsh factory floors or outdoor installations. The module’s hot-swap capability allows maintenance without system downtime, while its modular design facilitates scalability in large-scale automation setups.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IC670ALG230 |

| Manufacturer | GE |

| Product Type | Analog Input Module |

| Series | Genius Field Control |

| Input Signal | 4–20 mA / 0–20 mA (configurable) |

| Channels | 8 single-ended |

| Resolution | 12-bit |

| Analog Precision | 5.0 µA |

| Conversion Time | 60 µs per channel |

| Power Supply | 18–30 V DC (±10%) |

| Physical Dimensions | 10.85” (L) × 4.30” (W) × 2.25” (D) |

| Weight | 0.4 kg |

| Operating Temperature | -20°C to 70°C |

| Humidity | 5–95% non-condensing |

| Isolation | 1500 V AC (1 minute), 250 V AC continuous |

| Communication | Genius Bus via BIU (e.g., IC670GBI002) |

| Compliance | UL 508, IEC 61131-2, CE |

| Country of Origin | United States |

Note: Dimensions are inferred from GE’s IC660 series; actual values may vary slightly.

Main Features and Advantages

High Precision and Speed

The IC670ALG230 delivers 12-bit resolution and 5.0 µA precision, ensuring accurate measurement of process variables like pressure, temperature, and flow. Its 60-µs conversion time supports real-time control loops in fast-paced environments, such as automotive assembly lines or chemical reactors.

Rugged Industrial Design

With an IP65-rated housing, the module withstands dust, water splashes, and oil mist—critical for reliability in steel mills or wastewater treatment plants. Its -20°C to 70°C operating range and 1500 V AC isolation ensure stable performance in extreme conditions.

Flexible Configuration

The IC670ALG230 supports 4–20 mA or 0–20 mA input ranges, accommodating diverse sensors. Its single-ended grouped input design reduces wiring complexity, while the hot-swap capability allows field replacement without system shutdowns, minimizing downtime.

Seamless System Integration

As part of GE’s Genius Field Control ecosystem, the IC670ALG230 interfaces with IC670GBI002 Bus Interface Units for Genius Bus communication. It pairs with controllers like IC697CPU780 and analog modules such as IC670ALG240 (16-channel variant) to create scalable automation systems.

Cost-Effective Performance

The module’s modular design and reduced wiring requirements lower installation costs. Its low power consumption (50 mA typical) and long lifespan reduce operational expenses, making it ideal for cost-sensitive applications.

Application Fields

The GE IC670ALG230 excels in industries requiring reliable analog signal processing:

- Oil and Gas: Monitors pressure transmitters in wellheads and refineries, ensuring safe and efficient production. The module’s IP65 ratingprotects against corrosive environments.

- Power Generation: Measures steam turbine vibration sensors (via IC660BBA100) and adjusts generator load settings, optimizing energy output.

- Water Treatment: Processes flow meter signals in pump stations, enabling real-time adjustments to water distribution networks. The hot-swap capabilityensures continuous operation during maintenance.

- Food and Beverage: Calibrates temperature sensors in pasteurization systems, maintaining product quality. The module’s low power consumptionaligns with energy-efficient manufacturing goals.

Related Products

- GE IC670ALG240: 16-channel analog input module for high-density applications, offering double the channel count of the IC670ALG230.

- GE IC670GBI002: Genius Bus Interface Unit that bridges the IC670ALG230to the host PLC, enabling data exchange with controllers like IC697CPU780.

- GE IC660BBA100: Analog output module that pairs with the IC670ALG230to create closed-loop control systems, adjusting actuator setpoints based on sensor inputs.

- GE IC697CPU780: Genius series controller that processes data from the IC670ALG230, executing control logic for industrial processes.

- GE IC670CHS001: I/O terminal block that terminates field wiring for the IC670ALG230, simplifying installation in panel cabinets.

- GE IC670MDL740: Digital input module that complements the IC670ALG230in hybrid I/O systems, monitoring discrete signals alongside analog data.

Installation and Maintenance

Pre-installation preparations: Verify the Genius Bus network is powered and the IC670GBI002 BIU is correctly configured. Connect the IC670ALG230 to the BIU using a Genius Bus cable (e.g., IC660CBL105), ensuring proper grounding. Configure input ranges via GE’s programming software (e.g., Cimplicity) to match connected sensors.

Maintenance suggestions: Inspect the module quarterly for physical damage or loose connections, particularly in high-vibration environments. Clean the housing with a dry cloth to prevent dust buildup. Replace faulty channels immediately to avoid measurement errors. Update firmware annually using GE’s software to ensure compatibility with newer Genius modules. Store spare IC670ALG230 units in anti-static packaging to protect against electrostatic discharge.

Product Guarantee

Our company offers a one-year quality warranty service for the IC670ALG230, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import and export trade distribution company established in 2007 with 17 years of experience, we maintain a large stock of IC670ALG230 and other Genius series components, ensuring 48-hour delivery for urgent requirements. Our technical team provides user guides, firmware updates, and troubleshooting support to maximize device utility.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: