Description

GE IC660BBS102 Product Specification

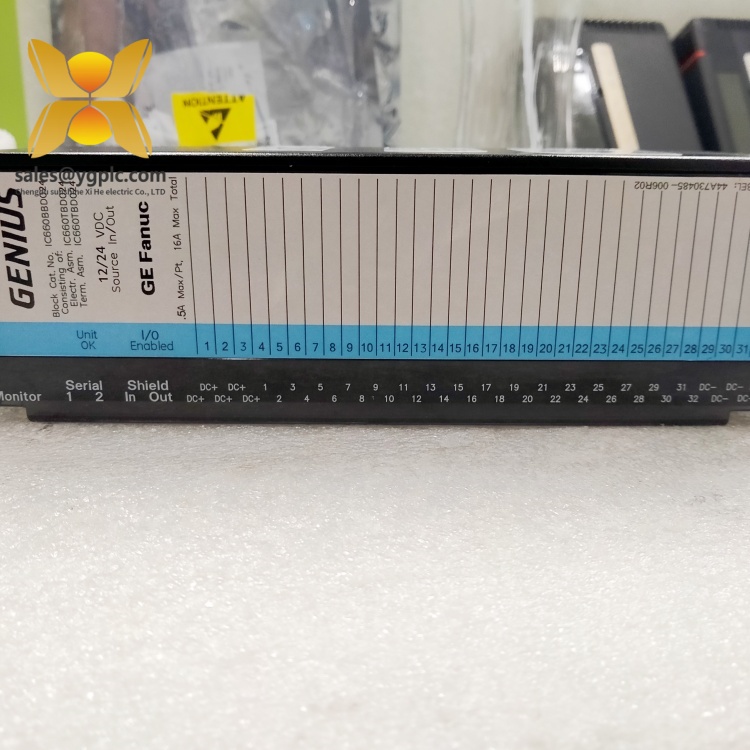

Product Overview

The GE IC660BBS102 is a versatile 8-point isolated discrete I/O block engineered for GE’s Genius I/O platform, designed to bridge field devices and PLC controllers in industrial automation systems. As a core component of the Genius distributed architecture, this module processes both discrete inputs (from sensors, switches) and outputs (to actuators, valves) in manufacturing, power generation, and process control applications, ensuring reliable signal transmission in harsh industrial environments.

Integrated into the Genius system, the GE IC660BBS102 features 8 configurable channels (mixed inputs/outputs) with 250 VAC/VDC isolation between groups, protecting against electrical surges and electromagnetic interference (EMI) from motors, welders, or high-voltage equipment. It supports diverse signal types, including dry contact switches, 24–125 VDC inputs, and 24 VDC outputs, making it compatible with proximity sensors, limit switches, and small actuators.

The GE IC660BBS102’s compact design (22.4 cm × 8.4 cm × 9.9 cm) and rugged construction—steel chassis with conformal coating—ensures operation in temperatures from 0°C to 60°C, with resistance to vibration (10–2000 Hz, 10 G rms) and humidity (5–95% non-condensing). Front-panel LEDs provide real-time status for power, module health, and individual channels, simplifying troubleshooting. Compatible with GE’s Proficy software, it allows easy configuration of input filtering and output behavior, while hot-swappable functionality minimizes downtime during maintenance—critical for continuous processes like automotive assembly or chemical batch production.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IC660BBS102 |

| Manufacturer | General Electric (GE) |

| Product Type | Isolated Discrete I/O Block |

| Series | Genius I/O Platform |

| I/O Channels | 8 (configurable as inputs/outputs) |

| Signal Types Supported | Dry contacts, 24–125 VDC (inputs); 24 VDC (outputs, 0.5 A max per channel) |

| Isolation | 250 VAC/VDC (between groups); 1500 VAC transient protection |

| Physical Dimensions | 22.4 cm (H) × 8.4 cm (W) × 9.9 cm (D) |

| Weight | 1.6 kg |

| Operating Temperature | 0°C to +60°C |

| Humidity | 5–95% non-condensing |

| Power Supply | 93–132 VAC or 105–132 VDC (field power); 5 VDC (logic, from backplane) |

| Mounting Type | Genius I/O rack mount (compatible with IC660CHS007 7-slot rack) |

| Certifications | CE, UL 508, IEC 61131-2 |

Main Features and Advantages

Robust Isolation for Noise Immunity:

The GE IC660BBS102’s 250 VAC/VDC isolation between channels and 1500 VAC transient protection shield against electrical noise and surges—critical in environments with motors, welders, or high-voltage equipment. This isolation prevents ground loops and signal corruption, ensuring reliable operation in steel mills or chemical plants where EMI is prevalent.

Flexible channel configuration:

With 8 configurable channels, the GE IC660BBS102 adapts to diverse applications—from monitoring 24 VDC proximity switches in automotive lines to controlling 24 VDC solenoid valves in packaging machines. Channels can be individually set as inputs or outputs via GE’s Proficy software, eliminating the need for specialized modules and reducing inventory costs.

Real-time diagnostics:

Front-panel LEDs (one per channel) provide instant visual feedback—green for active outputs, amber for detected inputs—allowing technicians to quickly identify faults like open circuits or shorted outputs. Built-in self-tests monitor power supply health and backplane communication, logging faults with timestamps to streamline troubleshooting and reduce mean time to repair (MTTR).

Rugged industrial design:

A conformal coating protects against dust, moisture, and chemical vapors, while the module’s wide operating temperature range (0°C to 60°C) and vibration resistance (10–2000 Hz, 10 G rms) ensure reliability in harsh settings—from desert power plants to offshore platforms. Its compact size optimizes cabinet space, ideal for retrofitting legacy systems.

Seamless Genius integration:

The GE IC660BBS102 connects directly to GE IC693BEM331 (Genius bus controller) and IC660CHS007 racks, enabling plug-and-play integration in distributed systems. Compatibility with the Genius protocol ensures high-speed data exchange (1 Mbps) with PLCs like the IC693CPU374, supporting real-time control in time-sensitive applications such as turbine auxiliary systems.

Hot-swappable operation:

The module supports hot swapping, allowing replacement without powering down the system. This feature cuts MTTR to under 15 minutes—vital for continuous processes like oil refining or food production, where unplanned downtime costs thousands per minute.

Application Areas

Manufacturing:

- Monitors limit switches on conveyor belts in electronics assembly lines, stopping operations if parts misalign to prevent damage.

- Controls pneumatic grippers in robotic cells, opening/closing based on proximity sensor inputs to handle components during welding or packaging.

Power Generation:

- Processes breaker status signals from generators, triggering protective relays via output channels during grid faults.

- Controls damper motors in boiler systems, adjusting airflow based on temperature switch inputs to optimize combustion efficiency

Oil and Gas:

- Monitors wellhead pressure switches, activating alarm lights via outputs when thresholds are exceeded to prevent overpressurization.

- Controls valve actuators in pipeline manifolds, opening/closing based on flow switch inputs to regulate product distribution.

Water/Wastewater:

- Detects float switch positions in storage tanks, triggering pump starts/stops via outputs to maintain safe water levels.

- Monitors filter pressure differential switches, activating backwash valves when clogs are detected to preserve treatment efficiency.

Related Products

- GE IC660CHS007: 7-slot rack housing GE IC660BBS102and other Genius modules, providing mechanical support and backplane connectivity.

- GE IC693BEM331: Genius bus controller that communicates with GE IC660BBS102, enabling data exchange with PLCs like the IC693CPU374.

- GE IC660HHM501: Handheld monitor for configuring GE IC660BBS102(e.g., input filtering, output defaults) without software.

- GE IC660EBD110: Electronic module enhancing GE IC660BBS102’s diagnostics with advanced fault logging and threshold adjustments.

- GE IC693PWR330: Power supply delivering stable 24 VDC to GE IC660BBS102and rack-mounted components.

- GE IC660BBS103: 16-point variant of GE IC660BBS102, ideal for larger systems needing more I/O channels.

Installation and Maintenance

Pre-installation preparations: Before installing GE IC660BBS102, verify the IC660CHS007 rack is grounded to prevent electrostatic discharge (ESD). Use an ESD wrist strap during handling. Mount the module in the rack with 30 mm clearance for airflow, securing with M4 screws (torque: 0.6 N·m). Connect field devices to terminal blocks—24 VDC sensors to input channels, actuators to outputs—ensuring correct polarity. Power the module via 93–132 VAC or 105–132 VDC, matching field device voltage requirements.

Maintenance suggestions: Perform monthly visual checks of GE IC660BBS102 LEDs to confirm normal operation (green for active outputs, amber for inputs). Clean dust from ventilation slots quarterly with compressed air. Annually, use a multimeter to verify output voltage (24 VDC ±5%) and check terminal connections for corrosion. Update firmware via Proficy software to access bug fixes. Test redundancy by swapping the module with a spare, ensuring seamless operation to minimize downtime.

Product Guarantee

Our company offers a one-year quality warranty service for GE IC660BBS102, covering hardware malfunctions not caused by human factors. During the warranty period, if GE IC660BBS102 shows abnormal performance (e.g., unresponsive channels, persistent faults), we will provide replacement services. As a leading import and export trade distribution company established in 2007 with 17 years of experience, we maintain large inventories—including unpopular and discontinued models—with a global supply chain to meet urgent spare part needs. Our stock ensures rapid delivery, supporting continuous operation of your industrial systems.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: