Description

GE IC610MDL179 Series Six Digital Input Module

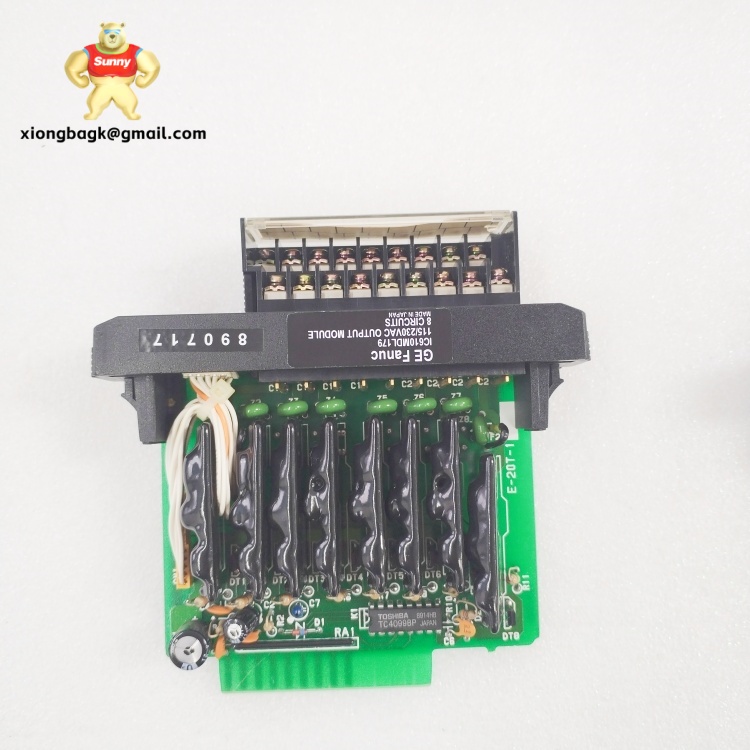

Product Overview

The GE IC610MDL179 is a high-performance digital input module designed for GE’s Series Six PLC system, a foundational component in industrial automation for manufacturing, energy, and infrastructure sectors. As a 16-channel module, the IC610MDL179 converts discrete signals from field devices—such as limit switches, pushbuttons, and proximity sensors—into digital data for processing by the Series Six controller, enabling real-time monitoring of equipment status and process conditions.

Engineered for versatility, the IC610MDL179 accepts 24V DC inputs with sinking/sourcing capability, supporting both NPN and PNP sensors without additional hardware. Its 1ms response time ensures rapid detection of signal changes, critical for time-sensitive applications like conveyor belt jams or emergency stop triggers. The module operates across 0°C to 60°C and withstands 5–95% non-condensing humidity, with a rugged metal housing that resists vibration and electromagnetic interference (EMI)—ideal for automotive plants and chemical facilities.

Within the Series Six ecosystem, the IC610MDL179 integrates seamlessly with controllers like IC610CPU101 and chassis such as IC610CHS130A, forming a cohesive digital input infrastructure. LED indicators provide real-time status for each channel, simplifying diagnostics and reducing troubleshooting time. Compliance with UL 508 and IEC 61131-2 standards underscores its reliability in regulated industries, where accurate input monitoring is essential for process safety.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC610MDL179 |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Series | Series Six |

| Input Channels | 16 |

| Input Voltage | 24V DC (±10%) |

| Input Type | Sinking/sourcing (NPN/PNP compatible) |

| Response Time | 1ms |

| Physical Dimensions | 127mm (L) × 89mm (W) × 51mm (D) |

| Weight | 0.45 kg |

| Operating Temperature | 0°C to 60°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Series Six chassis (backplane-mounted) |

| Isolation | Channel-to-channel: 250V AC |

| Compliance | UL 508, IEC 61131-2, CE |

| Country of Origin | United States |

Main Features and Advantages

High-Speed Signal Detection

The IC610MDL179’s 1ms response time ensures rapid detection of discrete signals, making it ideal for applications requiring immediate action—such as stopping a packaging line when a jam is detected or triggering an alarm for a door opening in a cleanroom. This speed minimizes process delays and reduces the risk of equipment damage.

Flexible Input Compatibility

Supporting both sinking and sourcing inputs, the module works with NPN and PNP sensors without reconfiguration, eliminating the need for separate modules. This flexibility simplifies inventory management and reduces installation time in facilities with mixed sensor types, such as automotive assembly lines using both proximity and limit switches.

Robust Industrial Design

Encased in a rugged metal housing, the IC610MDL179 operates reliably in harsh conditions: 0°C to 60°C temperatures, 10–500Hz vibration resistance, and 5–95% humidity. Its conformal coating protects against dust and moisture, ensuring long-term performance in food processing plants (with frequent washdowns) or steel mills (with high airborne particulates).

Channel Isolation

250V AC channel-to-channel isolation prevents signal interference, ensuring accurate readings even in noisy electrical environments. This is critical for facilities with large motors or welders, where electromagnetic noise can corrupt digital signals from proximity sensors.

Seamless Series Six Integration

The module plugs directly into Series Six chassis like IC610CHS130A, using the backplane for power and communication. It pairs with IC610CPU101 controllers and IC610CBL101 cables, forming a cohesive system that simplifies wiring and reduces troubleshooting complexity. LED indicators for each channel provide instant visual feedback, allowing technicians to quickly identify faulty sensors or wiring issues.

Application Fields

The GE IC610MDL179 is integral to industries requiring reliable digital input monitoring:

- Automotive Manufacturing: Tracks the position of robotic arms, conveyor belt status, and part presence in assembly lines. Its fast response time ensures timely adjustments to prevent collisions or misalignment.

- Food and Beverage: Monitors door interlocks, conveyor sensors, and fill level switches in packaging lines. The module’s rugged design withstands washdowns with caustic cleaners, ensuring compliance with hygiene standards.

- Water Treatment: Detects valve positions, pump run status, and flow switch activation in filtration systems. Its isolation prevents ground loops from affecting readings in plants with extensive sensor networks.

- Material Handling: Monitors pallet detection sensors and lift position switches in warehouse automation systems. The flexible input compatibility allows integration with both new and legacy sensors, reducing upgrade costs.

Related Products

- GE IC610MDL178: 8-channel digital input module with similar specifications, ideal for smaller systems requiring fewer inputs.

- GE IC610CPU101: Series Six controller that processes data from the IC610MDL179, executing logic to control industrial processes.

- GE IC610CHS130A: 10-slot chassis that houses the IC610MDL179 and other Series Six modules, providing power and backplane communication.

- GE IC610MDL240: Digital output module that works with the IC610MDL179 to actuate valves, motors, and alarms based on input signals.

- GE IC610PWR101: Power supply for Series Six chassis, delivering 24V DC to the IC610MDL179 and other modules.

- GE IC610CBL101: Shielded cable for connecting field sensors to the IC610MDL179, reducing electromagnetic interference in noisy environments.

Installation and Maintenance

Pre-installation preparations: Ensure the Series Six chassis is grounded and powered off. Verify the 24V DC power supply meets ±10% tolerance. Align the IC610MDL179 with the chassis guide rails, slide into place, and secure with retaining screws (torque to 0.8–1.0 N·m). Connect field sensors to the terminal block, using twisted-pair shielded cables for each channel. Label wires according to the system wiring diagram to simplify future maintenance.

Maintenance suggestions: Conduct monthly visual inspections to check for loose terminals, damaged wires, or dim channel LEDs. Clean dust from ventilation slots using compressed air to prevent overheating. Quarterly, test each channel by manually activating connected sensors and verifying LED activation. For unresponsive channels, check wiring continuity and sensor functionality before replacing the module. When replacing the IC610MDL179, label wires first and retest all channels post-installation to ensure proper operation.

Product Guarantee

Our company offers a one-year quality warranty service for the IC610MDL179, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import and export trade distribution company with 17 years of experience, we maintain extensive inventory of Series Six modules, ensuring 48-hour delivery for urgent requirements. Technical support includes wiring diagrams, compatibility guides, and troubleshooting assistance.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: