Description

GE IC610CHS130A Product Specification

Product Overview

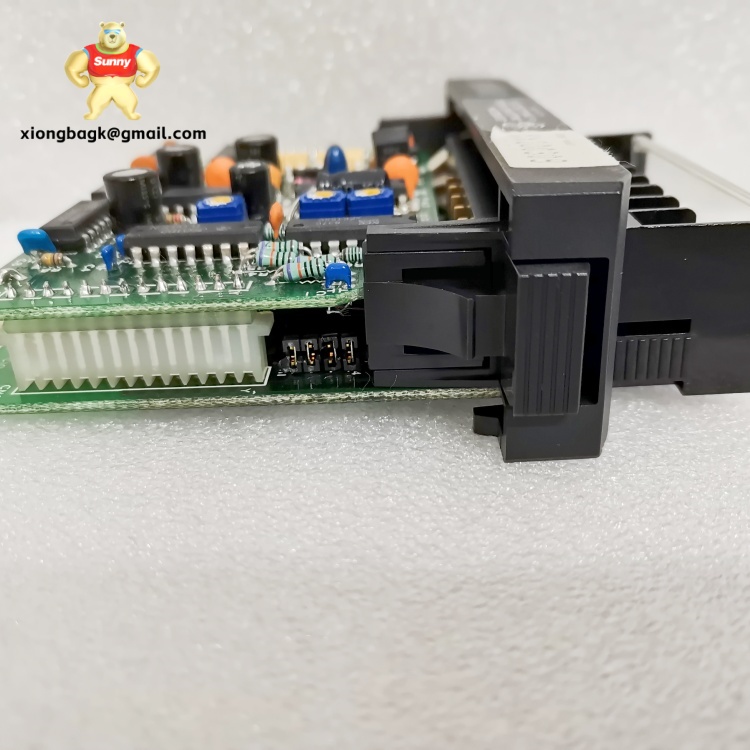

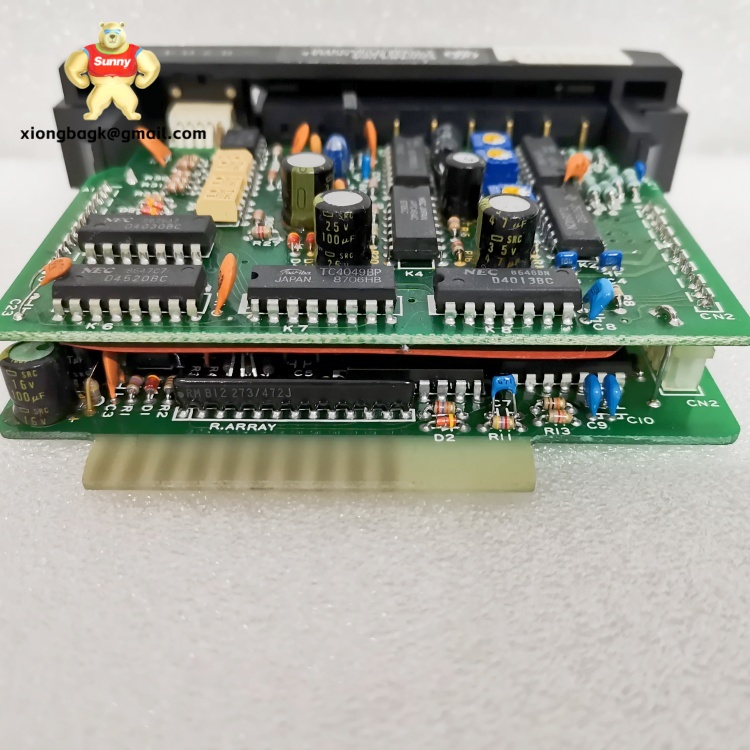

The GE IC610CHS130A is a robust 10-slot rack engineered for GE’s Series 610 PLC platform, serving as the mechanical and electrical backbone for housing and connecting PLC modules in industrial automation systems. As a critical component of the Series 610 architecture, this rack provides a standardized backplane for communication between CPUs, I/O modules, and power supplies, ensuring seamless data transfer and system coordination in manufacturing, power generation, and process control applications.

Designed to support the modular nature of the Series 610 system, the GE IC610CHS130A features 10 slots that accommodate various modules, including GE IC610CPU101 (CPU), GE IC610MDL110 (discrete I/O), and GE IC610ALG230 (analog modules). Its backplane operates at a data transfer rate of 1 Mbps, enabling real-time communication between modules to support time-sensitive control tasks.

The GE IC610CHS130A’s rugged construction—including a steel chassis and conformal coating—ensures durability in harsh industrial environments, withstanding temperatures ranging from 0°C to 60°C, vibration (10–2000 Hz, 10 G rms), and humidity (5–95% non-condensing). Its compact design (368 mm × 178 mm × 152 mm) and lightweight structure (2.3 kg) simplify installation in control cabinets, while compatibility with GE’s Proficy software allows easy configuration of module placement and backplane settings. This rack is essential for building scalable, reliable automation systems where modularity and ease of expansion are key.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC610CHS130A |

| Manufacturer | General Electric (GE) |

| Product Type | 10-Slot PLC Rack |

| Series | Series 610 PLC Platform |

| Number of Slots | 10 (accommodates Series 610 CPU, I/O, and specialty modules) |

| Backplane Data Rate | 1 Mbps |

| Physical Dimensions | 368 mm (H) × 178 mm (W) × 152 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | 0°C to +60°C |

| Humidity | 5–95% non-condensing |

| Power Input | 24 VDC (from external power supply, e.g., GE IC610PWR100) |

| Mounting Type | Panel mount (with M4 screws) |

| Material | Powder-coated steel chassis with conformal coating |

| Certifications | CE, UL 508, CSA C22.2 No. 142 |

Main Features and Advantages

Modular Flexibility:

The GE IC610CHS130A’s 10-slot design allows flexible configuration of Series 610 systems, enabling users to mix and match modules based on application needs. For example, in a food processing line, it can house a CPU, 4 discrete I/O modules, 2 analog modules, and a communication module—all connected via the integrated backplane. This modularity simplifies system expansion or reconfiguration, reducing downtime during upgrades.

The GE IC610CHS130A’s 10-slot design allows flexible configuration of Series 610 systems, enabling users to mix and match modules based on application needs. For example, in a food processing line, it can house a CPU, 4 discrete I/O modules, 2 analog modules, and a communication module—all connected via the integrated backplane. This modularity simplifies system expansion or reconfiguration, reducing downtime during upgrades.

Reliable Backplane Communication:

With a 1 Mbps backplane data rate, the GE IC610CHS130A ensures fast, synchronized data transfer between modules, critical for real-time control in time-sensitive applications like automotive assembly lines. The backplane’s redundant signal paths minimize communication failures, while gold-plated connectors reduce contact resistance and ensure long-term reliability.

With a 1 Mbps backplane data rate, the GE IC610CHS130A ensures fast, synchronized data transfer between modules, critical for real-time control in time-sensitive applications like automotive assembly lines. The backplane’s redundant signal paths minimize communication failures, while gold-plated connectors reduce contact resistance and ensure long-term reliability.

Rugged Industrial Construction:

The rack’s powder-coated steel chassis and conformal coating resist corrosion, dust, and chemical exposure, making it suitable for harsh environments such as chemical plants or offshore platforms. Its vibration resistance (10–2000 Hz, 10 G rms) and wide operating temperature range (0°C to +60°C) ensure stable performance in high-vibration settings like turbine halls or mining equipment.

The rack’s powder-coated steel chassis and conformal coating resist corrosion, dust, and chemical exposure, making it suitable for harsh environments such as chemical plants or offshore platforms. Its vibration resistance (10–2000 Hz, 10 G rms) and wide operating temperature range (0°C to +60°C) ensure stable performance in high-vibration settings like turbine halls or mining equipment.

Easy Installation and Maintenance:

The GE IC610CHS130A features tool-less module insertion, allowing quick installation or replacement of modules without specialized equipment. Front-panel mounting holes simplify secure attachment to control cabinets, while clear slot numbering (1–10) ensures proper module alignment. This design reduces installation time by up to 30% compared to legacy racks, a key advantage in fast-paced industrial settings.

The GE IC610CHS130A features tool-less module insertion, allowing quick installation or replacement of modules without specialized equipment. Front-panel mounting holes simplify secure attachment to control cabinets, while clear slot numbering (1–10) ensures proper module alignment. This design reduces installation time by up to 30% compared to legacy racks, a key advantage in fast-paced industrial settings.

Seamless Series 610 Integration:

The rack is fully compatible with all Series 610 modules, including GE IC610CPU101 (CPU), GE IC610PWR100 (power supply), and GE IC610MDL110 (discrete I/O). This compatibility ensures plug-and-play functionality, eliminating the need for custom wiring or adapters and simplifying system design for engineers.

The rack is fully compatible with all Series 610 modules, including GE IC610CPU101 (CPU), GE IC610PWR100 (power supply), and GE IC610MDL110 (discrete I/O). This compatibility ensures plug-and-play functionality, eliminating the need for custom wiring or adapters and simplifying system design for engineers.

Space-Efficient Design:

With dimensions of 368 mm × 178 mm × 152 mm, the GE IC610CHS130A optimizes cabinet space, making it ideal for compact control enclosures in mobile equipment or tight industrial spaces. Its lightweight (2.3 kg) construction also reduces stress on mounting structures, extending the life of control cabinets.

With dimensions of 368 mm × 178 mm × 152 mm, the GE IC610CHS130A optimizes cabinet space, making it ideal for compact control enclosures in mobile equipment or tight industrial spaces. Its lightweight (2.3 kg) construction also reduces stress on mounting structures, extending the life of control cabinets.

Application Areas

-

Manufacturing:

- Serves as the backbone for PLC systems in electronics assembly lines, housing modules that control robotic soldering, component placement, and quality inspection sensors.

- Supports packaging machinery by connecting CPUs to I/O modules that regulate filling, sealing, and labeling processes, ensuring consistent product quality.

-

Power Generation:

- Houses modules controlling auxiliary systems in coal-fired plants, such as boiler feedwater pumps and ash handling conveyors, optimizing energy usage and reducing downtime.

- Integrates with turbine control systems to monitor generator load and adjust fuel supply, maintaining stable grid synchronization during demand fluctuations.

-

Water/Wastewater:

- Enables automation of treatment plant filtration systems by connecting CPUs to analog modules that monitor water pressure and discrete modules that control backwash valves.

- Supports pump station control, with I/O modules regulating motor speeds based on level sensor data to prevent overflow or underflow.

-

Chemical Processing:

- Houses safety interlock modules in batch reactors, ensuring valves and pumps respond correctly to pressure or temperature alarms to prevent hazardous releases.

- Connects to communication modules for remote monitoring, allowing plant managers to track process data via SCADA systems.

Related Products

- GE IC610CPU101: Series 610 CPU module that fits into GE IC610CHS130A, serving as the system’s processing core for executing control logic.

- GE IC610PWR100: 24 VDC power supply module that mounts in GE IC610CHS130A to provide stable power to all connected modules.

- GE IC610MDL110: 16-point discrete input module that connects via GE IC610CHS130A’s backplane to send sensor data to the CPU.

- GE IC610ALG230: 8-channel analog input module whose process data (e.g., temperature, pressure) is transmitted through GE IC610CHS130A to the CPU.

- GE IC610CMM300: Communication module that fits into GE IC610CHS130A, enabling Ethernet/IP connectivity for remote monitoring.

- GE IC610CHS120A: 5-slot variant of GE IC610CHS130A, designed for smaller systems or space-constrained applications.

Installation and Maintenance

Pre-installation preparations: Before installing GE IC610CHS130A, verify the control cabinet is properly grounded to prevent electrostatic discharge (ESD). Use an ESD wrist strap during handling. Mount the rack using M4 screws (torque: 0.6 N·m) with 50 mm clearance for airflow. Ensure the cabinet temperature (0°C to +60°C) and humidity (5–95% non-condensing) meet specifications. Check compatibility of modules (e.g., GE IC610CPU101, GE IC610PWR100) with the rack’s slot assignments.

Maintenance suggestions: Perform monthly visual inspections of GE IC610CHS130A to check for loose screws or corrosion on connectors. Clean dust from ventilation slots with compressed air quarterly to maintain cooling. Annually, inspect backplane connectors for wear and re-tighten mounting screws to prevent vibration-induced loosening. Test module communication by swapping a known-good module into each slot to verify backplane functionality. Replace the rack every 15 years or if slots show signs of damage (e.g., bent pins) that affect module seating.

Product Guarantee

Our company offers a one-year quality warranty service for GE IC610CHS130A, covering hardware malfunctions not caused by human factors. During the warranty period, if GE IC610CHS130A shows abnormal performance—such as backplane communication failures or structural damage—we will provide replacement services. As a leading import and export trade distribution company established in 2007 with 17 years of experience, we maintain large inventories of industrial control parts, including many unpopular and discontinued models. Our supply channels ensure a large number of in-stock items to meet customers’ urgent needs for spare parts. For discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to procurement needs for scarce spare parts, supporting the continuous and stable operation of industrial systems.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: