Description

Honeywell CC-TUI041 Product Specification

Product Overview:Honeywell CC-TUI041

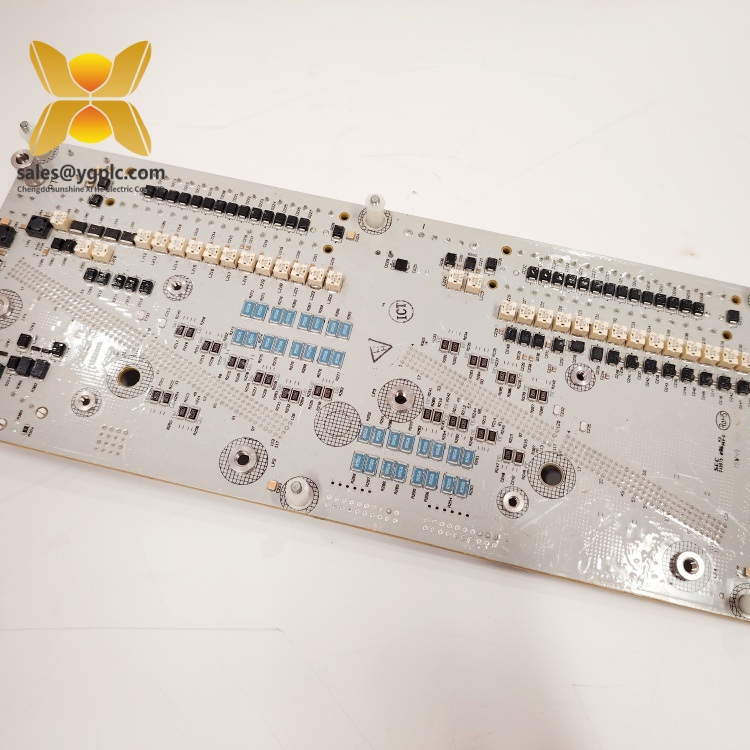

The Honeywell CC-TUI041 is a high-performance Universal Input/Output (UIO) Module engineered for industrial automation systems, particularly within Honeywell’s Experion PKS Distributed Control System (DCS). Designed to handle a wide range of analog and digital signals, the Honeywell CC-TUI041 serves as a critical interface between field devices (e.g., sensors, actuators) and the control system, ensuring seamless data acquisition and command execution in demanding environments. As part of Honeywell’s legacy TURBO series, this module combines rugged reliability with advanced diagnostic capabilities, making it ideal for industries such as oil and gas, power generation, and manufacturing where system uptime and precision are paramount.

With 32 configurable channels for analog input (AI), analog output (AO), digital input (DI), and digital output (DO), the Honeywell CC-TUI041 offers unmatched flexibility in hybrid control applications. It supports analog signals ranging from -10 to +10 VDC and 4–20 mA, while digital channels handle 24 VDC signals with surge protection. The module’s redundant design ensures continuous operation by providing backup components, while its conformal coating protects against dust, moisture, and electromagnetic interference (EMI) in harsh industrial settings. Measuring 8.5 x 5.5 x 2.5 inches (21.6 x 14 x 6.4 cm) and weighing 670g, the Honeywell CC-TUI041 fits seamlessly into standard 19-inch racks, enabling easy integration into existing or new control systems.

In automation architectures, the Honeywell CC-TUI041 acts as a frontline interface for real-time data processing. Its galvanic isolation feature safeguards the control system from electrical transients, while fault transparency allows the controller to maintain operation even if field devices fail. By supporting SCADA integration and open communication protocols, the module facilitates interoperability with third-party systems, enhancing system scalability and adaptability. Whether used in turbine control, process monitoring, or safety-critical applications, the Honeywell CC-TUI041 delivers the precision and reliability required to optimize industrial processes and reduce operational risks.

Technical Specifications:Honeywell CC-TUI041

| Parameter Name | Parameter Value |

|---|---|

| Product Model | Honeywell CC-TUI041 |

| Manufacturer | Honeywell |

| Product Type | Universal Input/Output (UIO) Module |

| Signal Channels | 32 configurable channels (AI, AO, DI, DO) |

| Analog Input Range | -10 to +10 VDC, 4–20 mA |

| Analog Output Range | 0 to +10 VDC, 4–20 mA |

| Digital I/O Voltage | 24 VDC (sink/source compatible) |

| Physical Dimensions | 8.5 x 5.5 x 2.5 inches (21.6 x 14 x 6.4 cm) |

| Weight | 670g |

| Operating Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Redundancy Support | Dual-channel redundancy for critical applications |

| Coating | Conformal coating for environmental protection |

| Certifications | ISO 9001, IEC 61131-2 (industrial control equipment) |

Honeywell CC-TUI041

Main Features and Advantages:Honeywell CC-TUI041

Multi-Protocol Flexibility: The Honeywell CC-TUI041 supports a wide range of industrial communication protocols, including Modbus and Profibus, enabling seamless integration with diverse field devices and control systems. This flexibility reduces the need for specialized hardware, simplifying system architecture and lowering costs.

Redundant Architecture: With dual-channel redundancy, the module ensures continuous operation even in the event of a channel failure. This feature is particularly critical in mission-critical environments such as power plants or offshore oil platforms, where downtime can lead to significant financial losses.

Advanced Diagnostics: Built-in self-test (BIST) functionality continuously monitors module health, providing real-time feedback on channel integrity, power supply stability, and thermal conditions. Faults are reported via front-panel LEDs and the control system’s HMI, allowing for proactive maintenance and minimizing mean time to repair (MTTR).

Universal Signal Handling: The module’s 32 configurable channels accommodate both analog and digital signals, making it suitable for hybrid control systems. Its high-resolution analog inputs (16-bit) and fast digital outputs enable precise measurement and rapid response to process changes, enhancing operational efficiency.

Rugged Industrial Design: Constructed with a reinforced metal casing and conformal-coated PCBs, the Honeywell CC-TUI041 resists harsh environmental conditions, including extreme temperatures, vibration, and EMI. This durability ensures reliable performance in challenging settings such as chemical plants or manufacturing facilities.

Application Areas:Honeywell CC-TUI041

The Honeywell CC-TUI041 is widely deployed in industries requiring robust and flexible I/O solutions:

-

Oil and Gas:

- Monitors pressure, temperature, and flow rates in refineries and offshore platforms, enabling real-time adjustments to optimize production.

- Supports safety interlocks and emergency shutdown systems (ESD) in SIL-rated applications.

-

Power Generation:

- Controls steam turbines and generators by processing sensor data (e.g., vibration, exhaust temperature) to ensure stable power output.

- Integrates with SCADA systems for remote monitoring of distributed power assets.

-

Manufacturing:

- Manages robotics, conveyor systems, and quality control devices in automotive and pharmaceutical production lines, ensuring synchronization and precision.

- Monitors equipment health using predictive maintenance algorithms, reducing unplanned downtime.

-

Water and Wastewater Treatment:

- Regulates pump stations and treatment processes by analyzing pH levels, flow rates, and chemical dosages, ensuring compliance with environmental standards.

- Provides remote access for diagnostic and configuration tasks, minimizing on-site maintenance needs.

-

Aerospace and Defense:

- Supports flight control systems and ground-based testing facilities by delivering high-precision signal conditioning and real-time data processing.

Related Products:Honeywell CC-TUI041

- Honeywell CC-TUI042: A Upgraded version of the Honeywell CC-TUI041 with enhanced cybersecurity features, ideal for applications requiring advanced threat protection.

- Honeywell CC-TUI043: A compact variant with 16 channels, suitable for space-constrained environments such as small-scale manufacturing plants.

- Honeywell CC-TUI044: A specialized module for high-speed pulse input/output, designed for applications requiring precise motion control.

- Honeywell CC-TUI045: A redundant I/O module with dual power supplies, offering enhanced reliability for mission-critical systems.

- Honeywell CC-TUI046: A fieldbus gateway module that extends the Honeywell CC-TUI041’s connectivity to include Ethernet/IP and PROFINET.

Honeywell CC-TUI041

Installation and Maintenance:Honeywell CC-TUI041

Pre-installation Preparation:

Before installing the Honeywell CC-TUI041, ensure the following:

Before installing the Honeywell CC-TUI041, ensure the following:

- Verify the power supply meets the module’s requirements (24 VDC ±10%) and that the control rack is properly grounded to prevent EMI interference.

- Use Honeywell’s Experion PKS engineering tools to configure channel types (AI/AO/DI/DO) and calibration parameters based on specific application needs.

- Ensure adequate airflow around the module to maintain optimal operating temperature, especially in high-density I/O configurations.

Maintenance Recommendations:

- Routine Inspections: Check front-panel LEDs monthly to confirm normal operation (e.g., green “Power” and “Health” indicators). Replace faulty modules immediately to avoid cascading system failures.

- Signal Calibration: Perform annual calibration of analog channels using certified test equipment to maintain measurement accuracy. Digital channels should be tested for response time using a pulse generator.

- Firmware Updates: Periodically update the module’s firmware via Honeywell’s Prognosis software to address security patches or enhance compatibility with newer control system versions.

- Environmental Checks: Clean dust and debris from the module’s vents quarterly, particularly in dusty environments, to prevent overheating. Monitor ambient temperature and humidity levels using the control system’s built-in sensors.

Product Warranty:Honeywell CC-TUI041

Our company provides a one-year quality warranty for the Honeywell CC-TUI041, covering hardware failures due to non-human factors. During the warranty period, we will replace the product if it exhibits performance anomalies or functional failures. For discontinued models or urgent needs, our global supply chain network ensures rapid response to scarce spare parts requests, supporting the continuous and stable operation of industrial systems.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This product description is based on publicly available technical data and industry applications. For detailed specifications, consult the official Honeywell datasheet or contact our technical support team.

ALSTOM I/OBE2 12004-104-00 V1.0.0 Network communication module

ALSTOM VPS 12004-102-03 V1.0.0 Control processor

TRICONEX DO2401 7400209-030 rack

TRICONEX AI3351 Digital 24VDC output module

TRICONEX 7400213-100 System

ABB 5SHY3545L0016 3BHB019719R0101 GVC736BE101 5SXE06-0160 encoder

ABB DSAI130A 3BSE018292R1 regulator

ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 I/O board

EPRO MMS6120 9100-00002C-08 driver

EPRO MMS6120 9100-00002-10 servo

WOODWARD 5453-277 Eddy current sensor

GE CK11CE300 Safety system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: