Description

HONEYWELL CC-TAOX61 – Series C Analog Output Termination Assembly for 4–20 mA/HART loops

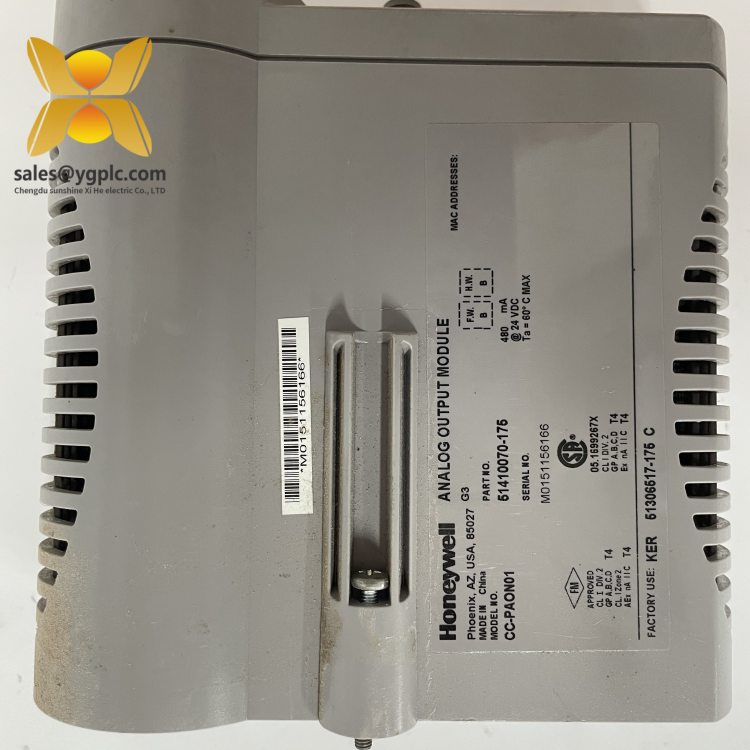

The HONEYWELL CC-TAOX61 is a Series C Termination Assembly engineered for analog output channels in Experion PKS systems (typically C300/C200). It provides the field-wiring interface for 4–20 mA outputs with HART, pairing with the corresponding Series C analog output I/O module to drive control valves, VFD references, and other actuators.

From my experience, plants choose the CC-TAOX61 when they want reliable, tidy field terminations and straightforward maintenance access without sacrificing HART diagnostics. You might notice that it’s designed to fit cleanly into standard Series C cabinets, which keeps retrofits predictable and panel layout simple.

Key Features

- Analog Output (4–20 mA) with HART support – When paired with the appropriate Series C AO I/O module, channels provide current output with HART pass-through for device configuration and diagnostics.

- Field-friendly terminations – Clearly labeled terminals and accessible test points (typical on Series C TAs) simplify loop checks, commissioning, and troubleshooting.

- Redundancy-ready architecture – Designed to work within Series C redundant I/O strategies, minimizing downtime in most cases.

- No separate TA power – The TA is powered via the I/O module backplane; no extra power supply or fusing required on the board itself.

- Compact, cabinet-friendly footprint – Fits a standard Series C TA position, keeping wiring density high without crowding the panel.

- Robust design for industrial environments – Typically supports a wide ambient range and is suited to control-room cabinets with proper ventilation.

Technical Specifications

| Brand / Model | HONEYWELL CC-TAOX61 (Series C Termination Assembly) |

| Function | Analog Output field-wiring interface for 4–20 mA/HART channels (used with the matching Series C AO I/O module) |

| Channel Capacity | Typically 8 AO channels per TA (channel count may depend on the paired I/O module) |

| Signal I/O Types | 4–20 mA current outputs with HART FSK overlay (when enabled by the AO I/O module) |

| Power Requirements | No separate TA power; powered via the Series C I/O backplane/IOM |

| Communication Interface | Backplane connection to the Series C AO I/O module; field side via screw-clamp terminals (typical) |

| Operating Temperature | Typically -20°C to +55°C in enclosed control cabinets (consult specific hardware revision) |

| Installation Method | Mounts in Series C I/O cabinet/rail as a standard TA; field wiring lands on labeled terminals |

| System Compatibility | Experion PKS Series C (C300/C200) AO I/O module with HART capability |

HONEYWELL CC-TAOX61

Application Fields

This TA finds its place across process industries where stable current outputs are needed:

- Refining & petrochemicals – valve positioners, flow control, and pressure control loops with HART diagnostics.

- Pharmaceuticals & specialty chemicals – dosing pumps and reactor jacket control where clean wiring and documentation matter.

- Pulp & paper / metals – speed references to drives or dampers, typically requiring steady 4–20 mA outputs.

- Power & utilities – feedwater valves, attemperator control, and other actuator loops in DCS cabinets.

Advantages & Value

- Reliability – Mature Series C hardware with stable behavior in most cases; fewer surprises during turnarounds.

- Compatibility – Works within Experion PKS architectures, leveraging HART pass-through to common asset management tools.

- Maintenance efficiency – Technicians appreciate the labeling and test-access; loops can be isolated quickly during calibration.

- Lifecycle cost – Standardized footprint and wiring save panel space and reduce engineering hours during expansions.

HONEYWELL CC-TAOX61

Installation & Maintenance

- Cabinet & environment – Install in a Series C control cabinet or equivalent enclosure with adequate ventilation. Avoid condensation; keep within the specified ambient range.

- Wiring practice – Use shielded twisted pairs for long analog runs; land shields per site standards (typically at one end). Verify polarity and loop integrity before enabling outputs.

- Grounding – Ensure cabinet ground and backplane bonding are intact to minimize noise on HART communication.

- Commissioning – Perform loop checks at 4 mA, 12 mA, and 20 mA; confirm HART device addressing and that pass-through is functioning via your asset tool.

- Routine maintenance – Periodically verify terminal tightness, clean dust from the cabinet, and update firmware on the associated I/O module when recommended by Honeywell.

- Safety – De-energize loops before touching field wiring. If used in a Div 2/Zone 2 area, follow the specific wiring methods for the certified hardware revision.

HONEYWELL CC-TAOX61

Quality & Certifications

- CE compliant; UL/CSA approvals are typical for Series C assemblies. RoHS conformity on many hardware revisions.

- Hazardous area ratings (e.g., Class I, Div 2 / Zone 2) may apply when installed as part of an approved Experion PKS system—best to confirm the exact suffix and hardware series.

- Manufacturer’s warranty: commonly 1-year limited; extended coverage is available via lifecycle service agreements.

Related Components (for planning)

- Series C Analog Output I/O Module (HART-capable) – mates with the CC-TAOX61 to provide channel electronics and diagnostics.

- Series C I/O Cabinet hardware – rails, backplane, and power distribution, sized per the I/O count and redundancy strategy.

- Asset management software – leverages HART pass-through for device configuration and condition monitoring.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: