Description

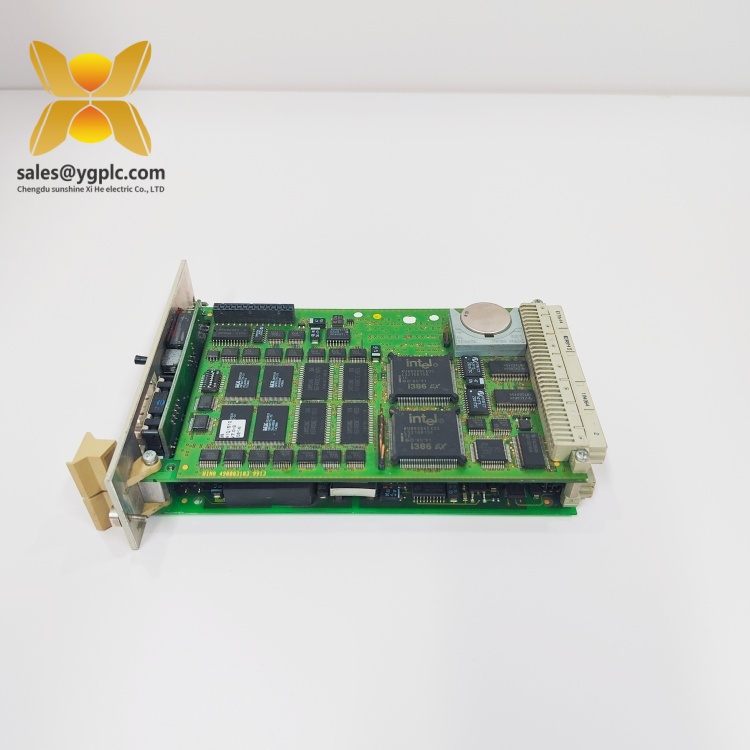

Product Overview: HIMA F8650E

Technical Specifications: HIMA F8650E

| Parameter Name | Parameter Value |

|---|---|

| Product Model | HIMA F8650E |

| Manufacturer | HIMA |

| Product Type | Safety Controller Module (TMR Architecture) |

| Safety Integrity Level | SIL 3 (IEC 61508/IEC 61511) |

| Power Supply | 24 VDC ±20% (dual isolated inputs for redundancy) |

| Physical Dimensions | 220 mm (W) × 160 mm (H) × 100 mm (D) |

| Weight | 1.5 kg |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-485, PROFIBUS DP |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5% to 95% non-condensing |

| Vibration Resistance | 5–50 Hz, 1.5 g (IEC 60068-2-6) |

| Certifications | ATEX, IECEx, UL, CSA, TÜV |

F8650E

Main Features and Advantages: HIMA F8650E

Scalable System Integration: As part of the H41q Series, the HIMA F8650E can be combined with other HIMA modules (e.g., I/O, communication) to build scalable safety systems, from small local applications to large, distributed architectures.

F8650E

Application Areas: HIMA F8650E

-

Oil and Gas:

- Upstream/Downstream: Controls emergency shutdown systems (ESD) in refineries, chemical plants, and offshore platforms, ensuring rapid response to leaks, overpressure, or fire incidents.

- Pipeline Networks: Monitors pressure and flow rates, triggering automatic isolation valves to prevent catastrophic failures.

-

Power Generation:

- Nuclear Plants: Manages safety interlocks and reactor protection systems, adhering to strict regulatory requirements.

- Thermal Power Stations: Controls turbine trips and boiler safety systems, preventing overspeeding or overheating.

-

Chemical and Pharmaceutical:

- Reactor Safety: Executes safety logic for hazardous chemical reactions, ensuring compliance with OSHA and EPA standards.

- Batch Processing: Monitors critical parameters (e.g., temperature, pH) and initiates safety protocols to prevent process deviations.

-

Heavy Manufacturing:

- Steel and Aluminum Production: Safeguards high-temperature processes by integrating with fire and gas detection systems.

- Paper Mills: Controls steam turbine safety systems and emergency stops for large machinery.

Related Products

- HIMA F8652: A redundant power supply module for the H41q Series, ensuring stable power delivery to the HIMA F8650E in dual-power configurations.

- HIMA F8607: A digital input module with SIL 3 certification, designed to interface with binary sensors (e.g., limit switches, pressure switches) in safety loops.

- HIMA F8617: A digital output module for driving actuators (e.g., solenoid valves, motor starters) in safety-critical control paths.

- HIMA F8627: An analog input module for processing continuous signals from transmitters (e.g., temperature, level), compatible with the HIMA F8650E for hybrid safety systems.

- HIMA F8640: A communication module supporting PROFINET and Ethernet/IP, enabling the HIMA F8650E to integrate with higher-level SCADA systems.

F8650E

Installation and Maintenance: HIMA F8650E

Before installing the HIMA F8650E, ensure the following:

- Verify the power supply meets the module’s requirements (24 VDC ±20%) and is properly grounded to prevent electrical noise.

- Use HIMA’s HiProject software to configure the module’s IP address, safety logic, and communication parameters before mounting it in the control cabinet.

- Ensure the installation environment complies with temperature/humidity specifications and provides adequate airflow for cooling.

- Routine Checks: Inspect front-panel LEDs weekly to confirm normal operation (e.g., green “Power” and “Health” indicators). Address any fault alerts immediately using the diagnostic tools in HiProject.

- Firmware Updates: Periodically update the module’s firmware to incorporate the latest safety patches and feature enhancements, following HIMA’s certified procedures to avoid configuration errors.

- Functional Testing: Perform annual proof testing of safety loops involving the HIMA F8650E to ensure compliance with SIL validation requirements. This includes simulating fault conditions and verifying correct logic execution.

- Environmental Maintenance: Clean dust and debris from the module’s vents quarterly, especially in dusty environments, to prevent overheating. Check for loose connections in terminal blocks during routine inspections.

F8650E

Product Warranty: HIMA F8650E

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This product description is based on technical data from HIMA’s official documentation and industry applications. For detailed configuration guidelines, refer to the HIMA F8650E user manual or contact our technical team for customized support.

HONEYWELL R7247C1001 Card piece

HONEYWELL TC-CCN014 convertor

Mitsubishi R28TB sensor

PIONEER MAGNETICS PM3398B-6-1-3-E 80026-172-24 Switch input module

WATLOW ANAFAZE 997D-11CC-JURG AO connection card

CAMERON AAP3798102-00130 Digital output terminal board

ABB S-093H 3BHB009885R0004 Logic control module

GE ACC-5595-208 350-805595-208N Switch input terminal board

Pacific Scientific SCE903A3-002-01 I/O fault diagnosis

Pacific Scientific SCE904AN-002-01 DCS module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: