Description

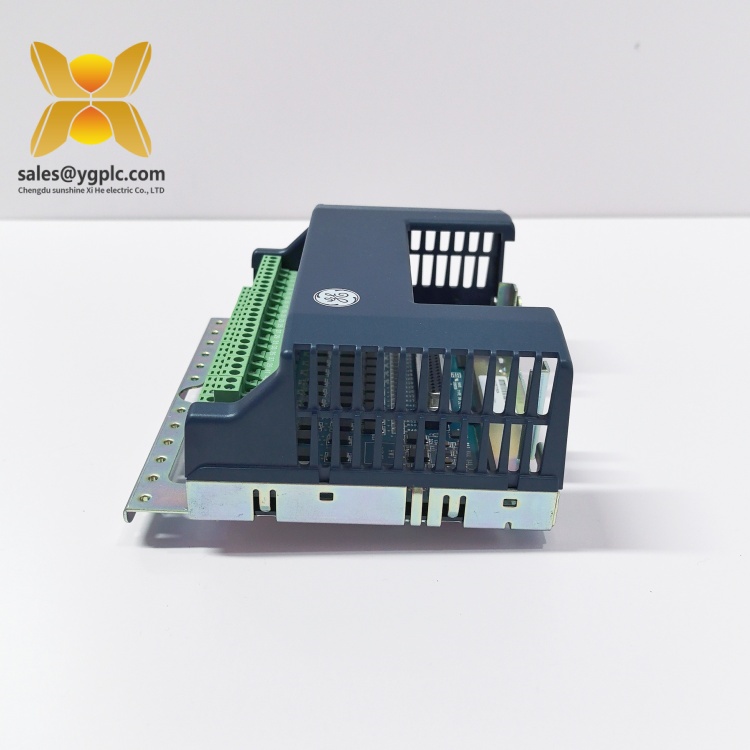

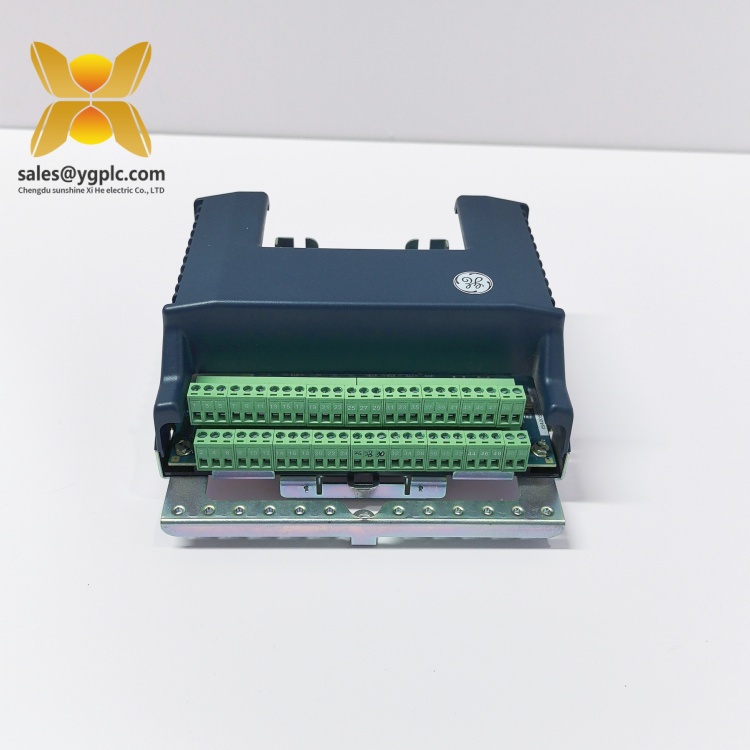

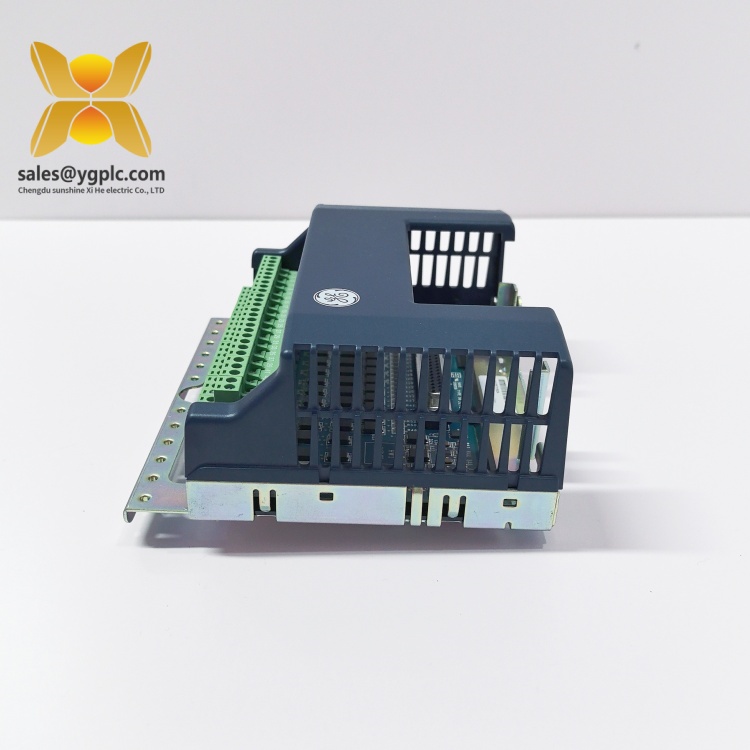

GE IS410STCIS2A Mark VIe Thermocouple Input Module

Product Overview

The GE IS410STCIS2A is a high-precision thermocouple input module designed for GE’s Mark VIe distributed control system, specializing in accurate temperature measurement and signal conditioning for industrial automation. As part of the IS410 Series, this module serves as a critical interface between thermocouple sensors and the Mark VIe controller, enabling real-time monitoring of high-temperature processes in power generation, oil & gas, and chemical processing.

Featuring 16 isolated thermocouple channels, the GE IS410STCIS2A supports a wide range of thermocouple types (J, K, T, E, R, S, B, N), with a measurement range of -200°C to +1800°C—making it versatile for applications from cryogenic processes to furnace monitoring. Its 24-bit analog-to-digital converter (ADC) delivers ±0.1°C accuracy and 0.01°C resolution, capturing minute temperature fluctuations critical for turbine health and reactor safety. The module’s galvanic isolation (2,500 Vrms) between channels and backplane protects against electromagnetic interference (EMI) and ground loops, ensuring signal integrity in noisy industrial environments.

In the Mark VIe ecosystem, the IS410STCIS2A integrates seamlessly with controllers like the IS400AEBMH3A and communication modules such as the IS400TCASH1A, forming a robust temperature monitoring loop. Its DIN-rail mounting design simplifies installation in compact cabinets, while front-panel LEDs provide real-time status updates for channel health and power. By combining high-channel density, rugged construction, and advanced signal processing, the IS410STCIS2A enhances process visibility and safety, making it indispensable for 24/7 industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS410STCIS2A |

| Manufacturer | GE |

| Product Type | Thermocouple Input Module |

| Series | Mark VIe |

| Channels | 16 isolated thermocouple inputs |

| Supported Types | J, K, T, E, R, S, B, N (configurable per channel) |

| Measurement Range | -200°C to +1800°C |

| Accuracy | ±0.1°C (0°C to +100°C); ±0.2°C (full range) |

| Resolution | 0.01°C |

| Isolation Rating | 2,500 Vrms (channel-to-channel, channel-to-backplane) |

| Physical Dimensions | 167 mm (H) × 148 mm (W) × 55 mm (D) |

| Weight | 0.6 kg |

| Operating Temperature | -40°C to +70°C |

| Certifications | CE, UL 508, IEC 61131-2, MIL-STD-810G |

| Power Requirements | 24 V DC ±10% (max 0.3 A) |

Main Features and Advantages

Broad Thermocouple Compatibility:

The IS410STCIS2A supports all standard thermocouple types, eliminating the need for multiple specialized modules. Each channel can be independently configured via GE’s Proficy software, adapting to diverse temperature ranges—from cryogenic storage (T-type) to high-temperature furnace monitoring (B-type).

Ultra-High Measurement Precision:

With a 24-bit ADC, ±0.1°C accuracy, and 0.01°C resolution, the module captures subtle temperature shifts in critical assets like turbine blades or reactor walls. This precision enables predictive maintenance, as even small deviations can indicate early wear or inefficiency.

Robust Galvanic Isolation:

2,500 Vrms isolation protects against EMI and ground loops, common in industrial environments with high-voltage equipment. This isolation ensures signal integrity in power plants and refineries, where electrical noise could distort temperature readings and compromise safety.

Rugged Environmental Design:

Conformal coating and MIL-STD-810G compliance allow operation in extreme temperatures (-40°C to +70°C), vibration, and humidity. This makes the IS410STCIS2A suitable for offshore platforms, desert power plants, and other harsh settings where equipment durability is non-negotiable.

Advanced Diagnostics:

Front-panel LEDs and firmware-level monitoring detect open circuits, short circuits, or thermocouple degradation, triggering alarms via the Mark VIe controller. These diagnostics reduce troubleshooting time, allowing maintenance teams to address issues before they affect operations.

Seamless Mark VIe Integration:

Interfaces directly with Mark VIe controllers via IONet, GE’s high-speed communication protocol, ensuring low-latency data transfer. It pairs with modules like the IS400SRLYS2ABB relay output module to form closed-loop control systems, adjusting heaters or coolers based on real-time temperature data.

Space-Efficient Design:

The compact DIN-rail form factor (167 mm × 148 mm × 55 mm) maximizes cabinet space, ideal for large-scale systems with multiple I/O modules. Its hot-swappable design allows replacement without system shutdown, minimizing downtime in 24/7 operations.

Application Areas

The GE IS410STCIS2A is critical in industries requiring precise high-temperature monitoring:

- Power Generation:

Monitors boiler tube temperatures, turbine exhaust gas, and generator stator windings in thermal and nuclear plants. Accurate data optimizes combustion efficiency and prevents overheating-related failures. - Oil & Gas:

Tracks temperatures in refinery distillation columns, catalytic crackers, and offshore wellheads. Ensures processes stay within safe ranges, preventing hazardous material breakdowns. - Chemical Processing:

Measures reactor vessel walls, heat exchanger surfaces, and polymerization tanks. Critical for maintaining reaction stability and product quality in batch manufacturing. - Metallurgy:

Monitors furnace temperatures in steel mills and foundries, ensuring precise heat treatment of metals. The module’s broad thermocouple support adapts to both low (annealing) and high (forging) temperature processes.

Specific applications include gas turbine exhaust temperature profiling, refinery hydrocracker monitoring, and chemical reactor thermal control.

Related Products

- GE IS410STCIS3A(Mark VIe Thermocouple Input Module):

An upgraded variant with 32 channels, suitable for large-scale systems like multi-zone furnaces. Shares the same precision and isolation as the IS410STCIS2A. - GE IS400AEBMH3A(Mark VIe PLC Controller):

Processes temperature data from the IS410STCIS2A, executing control logic to adjust heaters or coolers in closed-loop systems. - GE IS400TCASH1A(Mark VIe Terminal Board):

Consolidates thermocouple wiring, connecting field sensors to the IS410STCIS2A with surge protection to shield against voltage spikes. - GE IS220PSCAH1A 336A4940CSP9(Mark VIe Power Supply Module):

Provides stable 24 V DC power to the IS410STCIS2A, ensuring consistent performance in high-demand environments. - GE IS230STAOH2A(Mark VIe Analog Output Module):

Converts temperature-based control signals from the IS410STCIS2A into analog outputs, driving actuators like control valves or heating elements. - GE IS410PRTDI2A(Mark VIe RTD Input Module):

Complements the IS410STCIS2A by handling RTD sensors for lower-temperature applications, offering a complete temperature monitoring solution.

Installation and Maintenance

Pre-installation preparations:

Ensure the DIN rail is securely grounded and ventilated, with a stable 24 V DC power supply. Use shielded thermocouple extension wires (14–22 AWG) to minimize noise, routing them away from high-voltage lines. Configure thermocouple types and measurement ranges via Proficy software, verifying compatibility with the Mark VIe controller firmware.

Maintenance suggestions:

Perform monthly visual inspections of LED indicators to check for channel faults or power issues. Calibrate annually using a precision temperature bath and thermocouple simulator to maintain accuracy. Clean dust from vents quarterly with compressed air, especially in dusty environments like steel mills. Store spare IS410STCIS2A modules in anti-static packaging at 10–30°C with <50% humidity, testing them annually to confirm functionality.

Product Guarantee

Our company offers a one-year quality warranty service for the IS410STCIS2A, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import-export trade distribution company established in 2007 with 17 years of experience, we maintain large stocks of industrial control parts, including unpopular and discontinued models like the IS410STCIS2A, ensuring timely access for our customers.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: