Description

GE IS420YDOAS1B Mark VIe Discrete Output Module

Product Overview

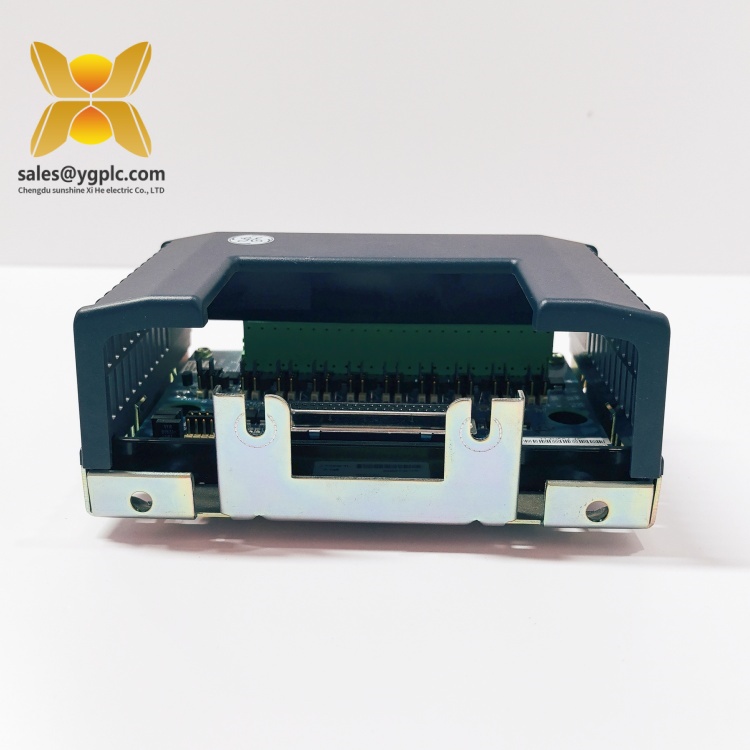

The GE IS420YDOAS1B is a high-reliability discrete output module designed for GE’s Mark VIe distributed control system, specializing in mission-critical industrial applications such as gas turbines, steam turbines, and marine propulsion systems. As part of the Innovation Series, this module serves as a vital component for managing automated drive assemblies, valve control, and safety interlocks, ensuring precise and timely actuation of field devices in harsh environments.

Engineered with a protective outer chassis and conformal coating, the IS420YDOAS1B withstands extreme temperatures (-40°C to +70°C), vibration, and humidity, making it suitable for offshore platforms, desert power plants, and chemical processing facilities 3. It interfaces seamlessly with GE’s Speedtronic control system, delivering 24 V DC output signals to drive solenoids, relays, and motors. The module supports hot-swappable operation, allowing maintenance without system downtime—a critical feature for 24/7 industrial operations.

With 16 isolated output channels, the IS420YDOAS1B ensures fail-safe operation by providing galvanic isolation between the control system and field devices. Its diagnostic capabilities include channel-level fault detection, which alerts operators to open circuits or shorted outputs via front-panel LEDs. By integrating with IONet industrial Ethernet switches (e.g., IS420ESWBH1A) and VME-based I/O modules, the IS420YDOAS1B forms a robust control loop that enhances operational efficiency and reduces lifecycle costs.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS420YDOAS1B |

| Manufacturer | GE |

| Product Type | Discrete Output Module |

| Series | Mark VIe |

| Output Channels | 16 (isolated) |

| Output Voltage | 24 V DC |

| Output Current | 0.5 A per channel (max) |

| Signal Type | Digital discrete (ON/OFF) |

| Isolation | Galvanic isolation (2,500 Vrms) |

| Communication | VME bus |

| Physical Dimensions | 160 mm (H) × 160 mm (W) × 120 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to +70°C |

| Certifications | CE, UL 508, ATEX Zone 2 (IIC), IEC 61131-2 |

| Mounting | 6U VME rack with conformal coating |

Main Features and Advantages

Rugged Design for Harsh Environments:

The IS420YDOAS1B’s conformal coating and MIL-STD-810G compliance protect against dust, moisture, and corrosive gases, ensuring reliable performance in offshore platforms and chemical plants. Its -40°C to +70°C temperature range makes it suitable for extreme climates 3.

The IS420YDOAS1B’s conformal coating and MIL-STD-810G compliance protect against dust, moisture, and corrosive gases, ensuring reliable performance in offshore platforms and chemical plants. Its -40°C to +70°C temperature range makes it suitable for extreme climates 3.

High-Speed Actuation:

With 16 isolated output channels, the module delivers rapid response times (<1 ms) to control critical processes like turbine fuel injection and emergency shutdowns. Each channel supports 0.5 A current, ensuring sufficient power to drive solenoids and relays in industrial machinery.

With 16 isolated output channels, the module delivers rapid response times (<1 ms) to control critical processes like turbine fuel injection and emergency shutdowns. Each channel supports 0.5 A current, ensuring sufficient power to drive solenoids and relays in industrial machinery.

Enhanced Safety and Diagnostics:

Galvanic isolation (2,500 Vrms) prevents ground loops and voltage spikes from damaging the control system. Front-panel LEDs provide real-time status monitoring, while built-in self-tests (BIST) detect open circuits or shorted outputs, reducing mean time to repair (MTTR) 3.

Galvanic isolation (2,500 Vrms) prevents ground loops and voltage spikes from damaging the control system. Front-panel LEDs provide real-time status monitoring, while built-in self-tests (BIST) detect open circuits or shorted outputs, reducing mean time to repair (MTTR) 3.

Seamless Integration with Mark VIe:

Interfaces with IONet switches and VME I/O modules (e.g., IS230TNPAH2A) via the Mark VIe’s VME bus, enabling plug-and-play integration. It pairs with Cimplicity HMI software for centralized monitoring and diagnostic insights.

Interfaces with IONet switches and VME I/O modules (e.g., IS230TNPAH2A) via the Mark VIe’s VME bus, enabling plug-and-play integration. It pairs with Cimplicity HMI software for centralized monitoring and diagnostic insights.

Hot-Swappable Operation:

Allows module replacement without system downtime, minimizing operational disruptions in power plants and marine vessels. This feature is particularly valuable in remote locations where maintenance access is limited.

Allows module replacement without system downtime, minimizing operational disruptions in power plants and marine vessels. This feature is particularly valuable in remote locations where maintenance access is limited.

Application Areas

The GE IS420YDOAS1B excels in industries requiring precise, reliable discrete control:

- Power Generation:

Controls gas turbine fuel valves, steam turbine bypass systems, and generator circuit breakers. Ensures rapid actuation during load changes or grid synchronization. - Oil & Gas:

Manages offshore platform compressors, pipeline isolation valves, and emergency shutdown (ESD) systems. Its rugged design withstands saltwater corrosion and vibration. - Marine Propulsion:

Regulates propulsion system clutches, thruster motors, and shipboard power distribution. Supports redundant configurations for naval and commercial vessels. - Industrial Manufacturing:

Controls conveyor belts, robotic arms, and process pumps in steel mills and chemical plants. Enables synchronized operation of multiple devices for high-throughput production.

Specific applications include turbine governor control, refinery flare gas management, and marine engine load balancing.

Related Products

- GE IS420ESWBH1A (Mark VIe IONet Switch):

Provides high-speed, redundant communication between the IS420YDOAS1B and other Mark VIe modules, ensuring real-time data exchange 11. - GE IS230TNPAH2A (Mark VIe DIO Module):

Complements the IS420YDOAS1B with digital input capabilities, forming a complete I/O solution for turbine auxiliary systems. - GE IS220PSCAH1A 336A4940CSP9 (Mark VIe Power Supply):

Offers redundant 24 V DC power to the IS420YDOAS1B, ensuring uninterrupted operation in mission-critical systems 11. - GE IS410STCIS2A (Mark VIe Thermocouple Module):

Feeds temperature data from turbine components to the IS420YDOAS1B, enabling closed-loop control of cooling systems. - GE IS215ACLEH1A (Mark VIe Application Control Layer Module):

Handles system logic and interface processing, sharing the same VME bus architecture as the IS420YDOAS1B. - GE IS230TDBTH6A (Mark VIe Terminal Board):

Organizes wiring between field devices and the IS420YDOAS1B, simplifying installation and reducing connection errors.

Installation and Maintenance

Pre-installation preparations:

Verify the VME rack is securely grounded and ventilated, with sufficient space for cooling. Install the IS420YDOAS1B in a 6U VME slot, aligning it with the backplane. Connect shielded cables to the module’s terminals, ensuring proper polarity for 24 V DC power. Configure output channels via GE’s Proficy software, assigning each channel to its respective field device.

Verify the VME rack is securely grounded and ventilated, with sufficient space for cooling. Install the IS420YDOAS1B in a 6U VME slot, aligning it with the backplane. Connect shielded cables to the module’s terminals, ensuring proper polarity for 24 V DC power. Configure output channels via GE’s Proficy software, assigning each channel to its respective field device.

Maintenance suggestions:

Perform quarterly firmware updates to ensure compatibility with the latest Mark VIe software. Inspect front-panel LEDs monthly to confirm normal operation; address faults (e.g., red LEDs) using system diagnostics. Clean dust from vents biannually with compressed air, especially in dusty environments. Replace the module every 10 years or as recommended by GE’s lifecycle guidelines. Store spare IS420YDOAS1B modules in anti-static packaging at 10–30°C with <50% humidity, testing them annually to validate functionality.

Perform quarterly firmware updates to ensure compatibility with the latest Mark VIe software. Inspect front-panel LEDs monthly to confirm normal operation; address faults (e.g., red LEDs) using system diagnostics. Clean dust from vents biannually with compressed air, especially in dusty environments. Replace the module every 10 years or as recommended by GE’s lifecycle guidelines. Store spare IS420YDOAS1B modules in anti-static packaging at 10–30°C with <50% humidity, testing them annually to validate functionality.

Product Guarantee

Our company offers a one-year quality warranty service for the IS420YDOAS1B, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import-export trade distribution company established in 2007 with 17 years of experience, we maintain large stocks of industrial control parts, including unpopular and discontinued models like the IS420YDOAS1B, ensuring timely access for our customers.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: