Description

GE IS410TRLYS1B Mark VIe TMR Relay Output Terminal Board

Product Overview

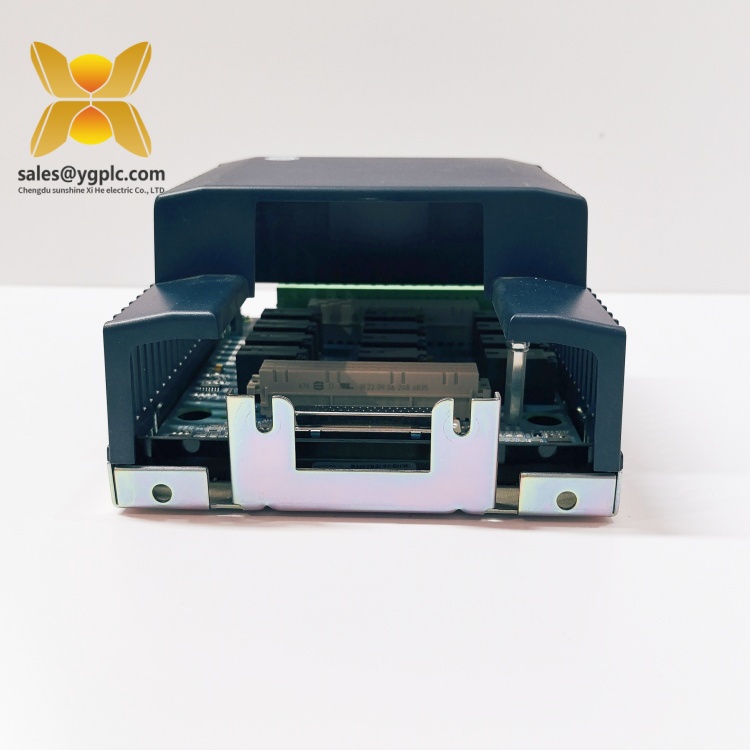

The GE IS410TRLYS1B is a high-reliability triple modular redundancy (TMR) relay output terminal board designed for GE’s Mark VIe Speedtronic™ turbine control system, a cornerstone of power generation, oil and gas, and industrial automation. As a critical interface component, this board provides 12 Form-C relay output circuits with isolated contact pairs, enabling redundant control of high-power devices such as solenoid valves, motor starters, and emergency shutdown actuators in safety-critical applications. The IS410TRLYS1B integrates seamlessly with Mark VIe TMR I/O packs like IS420YDOAS1B and IS220YDOAS1A, translating digital commands from the control system into discrete relay outputs with triple-path redundancy to prevent single-point failures.

Engineered for ruggedness, the IS410TRLYS1B features a DIN rail-mountable design with pluggable Euro-style terminal blocks, facilitating easy installation and maintenance in compact control cabinets. Its metal enclosure ensures durability in harsh environments with temperatures ranging from -40°C to +70°C, while 500V DC isolation between channels and ground safeguards against electromagnetic interference—critical for signal integrity in turbine control systems. The board supports TMR architecture, where three independent relay paths cross-validate outputs, ensuring fail-safe operation in nuclear and offshore applications.

Within the Mark VIe ecosystem, the IS410TRLYS1B acts as a bridge between the TMR control processor and field devices, delivering reliable relay switching with real-time diagnostic feedback via LED indicators. Compliance with UL 508 and IEC 61508 (SIL 2) standards underscores its reliability in regulated industrial settings, where safety and uptime are paramount.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS410TRLYS1B |

| Manufacturer | GE |

| Product Type | TMR Relay Output Terminal Board |

| Series | Mark VIe Speedtronic™ |

| Output Channels | 12 Form-C relays (2A per channel, 3 paths/TMR) |

| Signal Isolation | 500V DC (channel-to-channel, channel-to-ground) |

| Power Supply | 24V DC (±10%, redundant inputs) |

| Physical Dimensions | 228 mm (L) × 152 mm (W) × 76 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail-mounted (35mm standard) |

| Compliance | UL 508, IEC 61010, IEC 61508 (SIL 2) |

| Country of Origin | United States |

Main Features and Advantages

TMR architecture: The IS410TRLYS1B employs triple modular redundancy, with three independent relay paths per channel that cross-validate outputs. This design ensures that a single relay failure does not disrupt operation, making it ideal for safety instrumented systems (SIS) in nuclear power plants and offshore platforms where failure risks catastrophic consequences.

High-power handling: Each of the 12 Form-C relays supports up to 2A continuous current, enabling direct control of high-power devices such as solenoid valves and motor contactors without intermediate relays. This reduces system complexity and potential failure points in turbine control loops.

Industrial-grade durability: Encased in a rugged metal housing, the IS410TRLYS1B operates reliably across -40°C to +70°C, withstanding vibration, humidity, and corrosive atmospheres common in refineries and chemical plants. Its 500V DC isolation prevents ground loops and electromagnetic interference, ensuring signal integrity in electrically noisy environments.

Seamless TMR integration: The board is purpose-built to pair with Mark VIe TMR I/O packs like IS420YDOAS1B, which provide redundant control signals. This compatibility simplifies retrofits of legacy systems to TMR architectures, enhancing safety without extensive reengineering.

Real-time diagnostics: LED indicators on the board and paired I/O packs provide instant feedback on relay status, power health, and communication faults. This allows technicians to quickly identify issues during maintenance, reducing downtime in 24/7 operations such as power generation.

Flexible mounting: The DIN rail design and pluggable terminal blocks enable quick installation and replacement, with double-stacking capability to maximize space in crowded control cabinets—a critical feature in marine and offshore applications with limited space.

Application Fields

The GE IS410TRLYS1B is essential in industries requiring redundant relay control for safety-critical systems:

- Power Generation: In nuclear and thermal plants, it controls steam turbine bypass valves, generator circuit breakers, and auxiliary system relays. Its TMR architecture meets nuclear safety standards (e.g., 10CFR50) for reactor protection systems, ensuring fail-safe operation during transient conditions.

- Oil and Gas: Offshore platforms use the IS410TRLYS1Bto manage emergency shutdown (ESD) valves, compressor anti-surge controls, and fire suppression system relays. Its rugged design withstands salt spray and vibration, while TMR ensures reliable operation in remote, unmanned facilities.

- Industrial Manufacturing: Chemical plants deploy the board to control process isolation valves, mixer drives, and emergency stop circuits in hazardous areas. The high relay capacity eliminates the need for intermediate switching, reducing latency in critical control loops.

- Marine Propulsion: Shipboard turbine systems rely on the IS410TRLYS1Bto control engine throttle relays, rudder actuators, and bilge pump motors. Its compact size and vibration resistance make it suitable for marine environments, where space and reliability are paramount.

Related Products

- GE IS420YDOAS1B: A TMR discrete output I/O pack that provides triple-path control signals to the IS410TRLYS1B, forming a complete redundant relay control system.

- GE IS220YDOAS1A: A safety-rated discrete output I/O pack compatible with the IS410TRLYS1Bfor simplex-to-TMR hybrid systems, ideal for retrofits.

- GE IS220PAICH2A: A redundant 24V DC power supply that delivers triple-path power to the IS410TRLYS1Band paired I/O packs, enhancing system resilience.

- GE IS400WROBH1A: A fused power distribution daughterboard that adds overcurrent protection to the IS410TRLYS1B, critical for ESD applications in hazardous areas.

- GE IS410STAIS2A: A TMR analog I/O terminal board that integrates with the IS410TRLYS1Bin systems requiring both analog monitoring and discrete control.

- GE IS200TRLYS1BGG: A non-TMR relay terminal board with 120V AC compatibility, serving as a cost-effective alternative to the IS410TRLYS1Bin non-safety applications.

Installation and Maintenance

Pre-installation preparations: Verify the DIN rail is securely grounded and rated for the board’s weight. Ensure the 24V DC power supply meets ±10% tolerance and is connected to redundant sources. Align the IS410TRLYS1B with the rail, secure with clips, and torque terminal screws to 0.8–1.0 N·m. Label wires according to GE’s wiring diagrams, ensuring each TMR path connects to the corresponding I/O pack channel. Test continuity of relay contacts before energizing to avoid short circuits.

Maintenance suggestions: Conduct monthly visual inspections to check for loose terminals, damaged wires, or dim LED indicators—signs of potential relay degradation. Clean dust from ventilation slots using compressed air to prevent overheating. Quarterly, test relay operation by energizing each channel and verifying contact closure with a multimeter. For TMR validation, simulate a single path failure and confirm the system maintains output via the remaining paths. When replacing the IS410TRLYS1B, label TMR path wires individually to preserve redundancy during reinstallation.

Product Guarantee

Our company offers a one-year quality warranty service for the IS410TRLYS1B, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

As a leading enterprise in the industrial control industry established in 2007, with 17 years of experience, we are an import and export trade distribution company specializing in industrial control spare parts. We stock a large quantity of both common and unpopular discontinued models, ensuring we meet urgent customer needs with our supply channel advantages.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: