Description

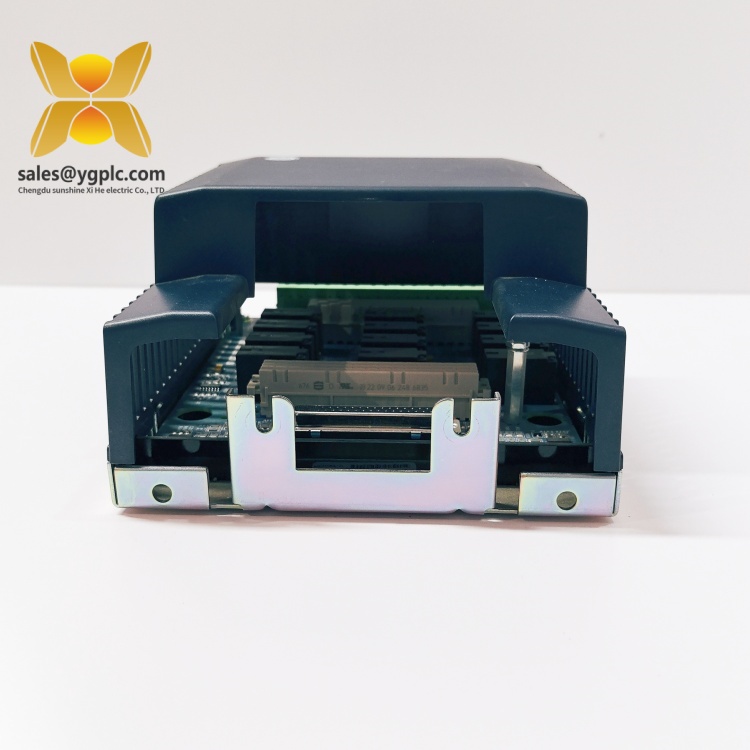

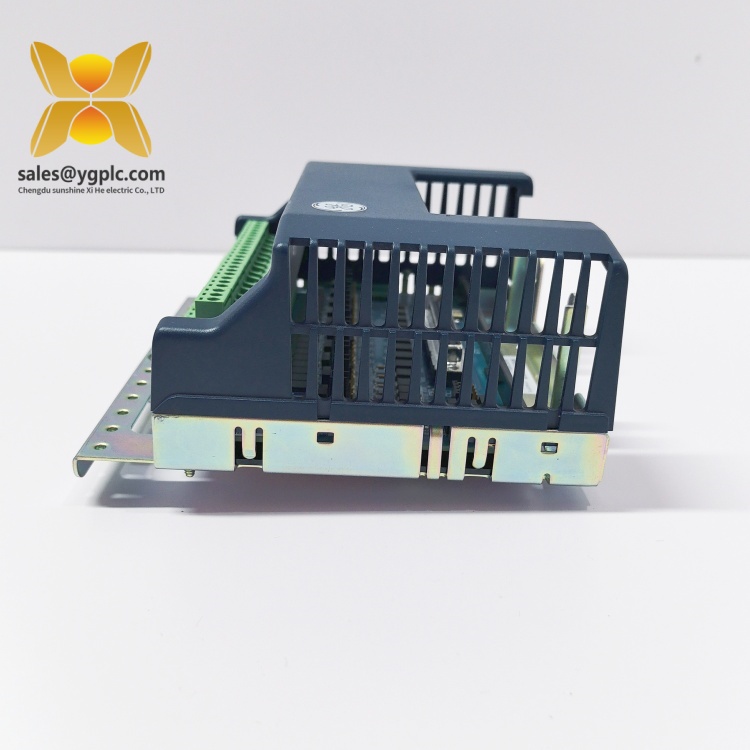

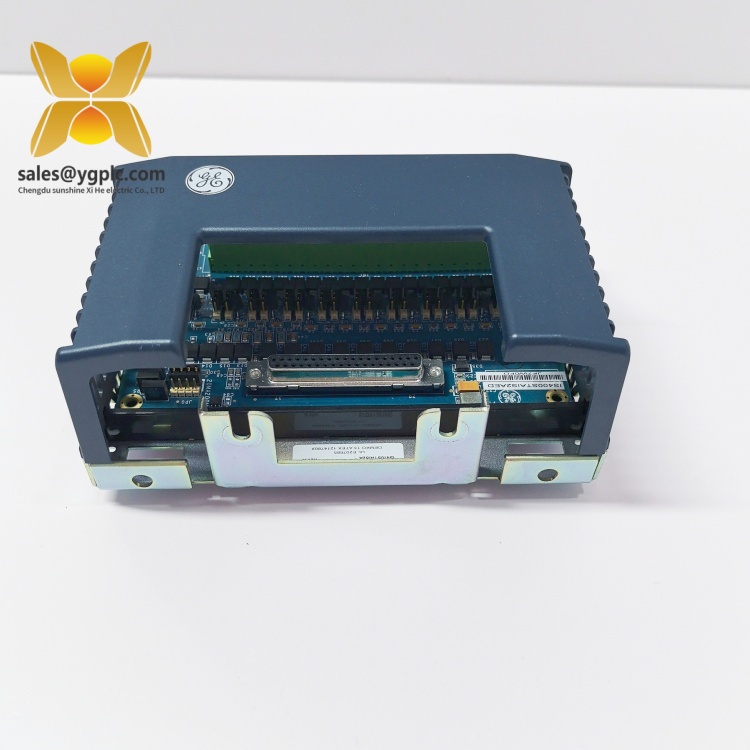

GE IS410SRLYS2A Mark VIe Simplex Relay Output Terminal Board

Product Overview

The GE IS410SRLYS2A is a high-performance simplex relay output terminal board designed for GE’s Mark VIe Speedtronic™ turbine control system, a cornerstone of power generation, oil and gas, and industrial automation. As a critical interface component, this board provides 12 Form-C relay output circuits with isolated contact pairs for position feedback, enabling precise control of high-power devices such as solenoid valves, motor starters, and process actuators in safety-critical applications1. The IS410SRLYS2A integrates seamlessly with Mark VIe I/O packs like IS220YDOAS1A and IS420YDOAS1B, translating digital commands from the control system into discrete relay outputs for field equipment.

Engineered for ruggedness, the IS410SRLYS2A features a 7-inch DIN rail-mountable design with pluggable Euro-style terminal blocks, allowing for easy installation and maintenance in compact control cabinets. Its double-stacking capability maximizes space efficiency, while the metal enclosure ensures durability in harsh environments with temperatures ranging from -40°C to +70°C1. The board supports optional daughterboards like IS400WROBH1A, which adds fused power distribution and dedicated power channels for enhanced functionality in complex systems.

Within the Mark VIe ecosystem, the IS410SRLYS2A acts as a bridge between the control processor and field devices, delivering reliable relay switching with diagnostic feedback. Compliance with UL 508 and IEC 61010 standards underscores its reliability in regulated industrial settings, where safety and uptime are paramount.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS410SRLYS2A |

| Manufacturer | GE |

| Product Type | Simplex Relay Output Terminal Board |

| Series | Mark VIe Speedtronic™ |

| Output Channels | 12 Form-C relays (2A per channel) |

| Signal Isolation | 500V DC (channel-to-channel, channel-to-ground) |

| Power Supply | 24V DC (±10%) |

| Physical Dimensions | 178 mm (L) × 102 mm (W) × 64 mm (D) |

| Weight | 0.8 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail-mounted |

| Compliance | UL 508, IEC 61010, CE |

| Country of Origin | United States |

| Terminal Type | Pluggable Euro-style box terminals |

| Daughterboard Support | IS400WROBH1A (fused power distribution) |

Main Features and Advantages

High-Capacity Relay Control: The IS410SRLYS2A delivers 12 isolated Form-C relay outputs, each rated for 2A continuous current, making it suitable for controlling high-power equipment in power plants and refineries. The isolated contact pairs provide real-time feedback to the I/O pack, enabling diagnostic monitoring of relay status and coil health1.

Modular Expandability: With support for the IS400WROBH1A daughterboard, the IS410SRLYS2A can be upgraded to include fused power distribution for the first six relays and dedicated power for the seventh, enhancing safety and reliability in critical applications like emergency shutdown (ESD) systems1.

Industrial-Grade Durability: Built with a metal enclosure and operating range of -40°C to +70°C, the IS410SRLYS2A withstands extreme temperatures, vibration, and corrosive environments. Its robust design ensures long-term performance in offshore platforms and chemical processing plants.

Space-Saving Design: The 7-inch DIN rail mount and double-stacking capability allow multiple boards to be installed in tight spaces, reducing cabinet size and wiring complexity. The pluggable terminal blocks simplify field wiring, minimizing installation time.

Diagnostic Visibility: LED indicators on the I/O pack provide real-time status of relay operation and fault conditions, enabling rapid troubleshooting. This feature is critical for maintaining uptime in 24/7 industrial operations.

Application Fields

The GE IS410SRLYS2A is essential in industries requiring reliable relay control for turbine and industrial systems:

- Power Generation: In thermal and nuclear plants, it controls steam turbine bypass valves, generator circuit breakers, and auxiliary motor starters. The board’s diagnostic feedback ensures safe and efficient load shedding during grid disturbances.

- Oil and Gas: Offshore platforms use the IS410SRLYS2Ato manage compressor anti-surge valves, pump control relays, and ESD actuators. Its rugged design and fused power options (via IS400WROBH1A) ensure fail-safe operation in hazardous environments.

- Industrial Manufacturing: Chemical plants deploy the board to automate process valves, conveyor belts, and mixer drives. The high channel density and modular design simplify integration into complex production lines.

- Marine Propulsion: Shipboard turbine systems rely on the IS410SRLYS2Ato control engine throttle relays, rudder actuators, and emergency stop circuits. Its compact size and vibration resistance make it ideal for marine applications.

Related Products

- GE IS220YDOAS1A: A safety discrete output I/O pack that pairs with the IS410SRLYS2Ato provide redundant control in safety instrumented systems (SIS).

- GE IS400WROBH1A: A daughterboard that adds fused power distribution to the IS410SRLYS2A, enhancing safety in high-risk applications like ESD systems.

- GE IS200TRLYS1BGG: A relay output terminal board with partial power protection for systems using 120/240V AC sources, complementary to the IS410SRLYS2Ain hybrid power environments.

- GE IS410STAIS2A: A simplex analog I/O terminal board that integrates with the IS410SRLYS2Afor systems requiring both analog and discrete control.

- GE IS420YDOAS1B: A discrete output I/O pack with 12 relay/coil monitors, designed for triple modular redundancy (TMR) systems alongside the IS410SRLYS2A.

- GE IS220PAICH2A: A redundant power supply that ensures uninterrupted 24V DC to the IS410SRLYS2Aand other Mark VIe components.

Installation and Maintenance

Pre-installation preparations: Verify the DIN rail is securely grounded and has sufficient space for the IS410SRLYS2A and any daughterboards. Ensure the 24V DC power supply meets voltage tolerances (±10%). Align the board with the rail, secure it with clips, and torque terminal screws to 0.8–1.0 N·m for reliable connections12. Label wires according to the wiring diagram and test continuity before connecting to field devices.

Maintenance suggestions: Conduct monthly visual inspections to check for loose terminals, damaged wires, or LED warnings. Clean dust from the board using compressed air to prevent overheating. Quarterly, test relay contacts with a multimeter to ensure proper operation. When replacing the IS410SRLYS2A, label wires before removal and retest all channels post-installation. For daughterboard-equipped systems, inspect fuses in the IS400WROBH1A every six months.

Product Guarantee

Our company offers a one-year quality warranty service for the IS410SRLYS2A, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems.

As a leading import and export trade distribution company with 17 years in the industrial control industry, we stock a large inventory of both common and hard-to-find models, ensuring we meet urgent spare part needs. Our expertise in GE and other major brands allows us to deliver reliable support for your automation systems.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: