Description

GE IS400SRLYS2ABB Mark VIe Relay Output Module

Product Overview

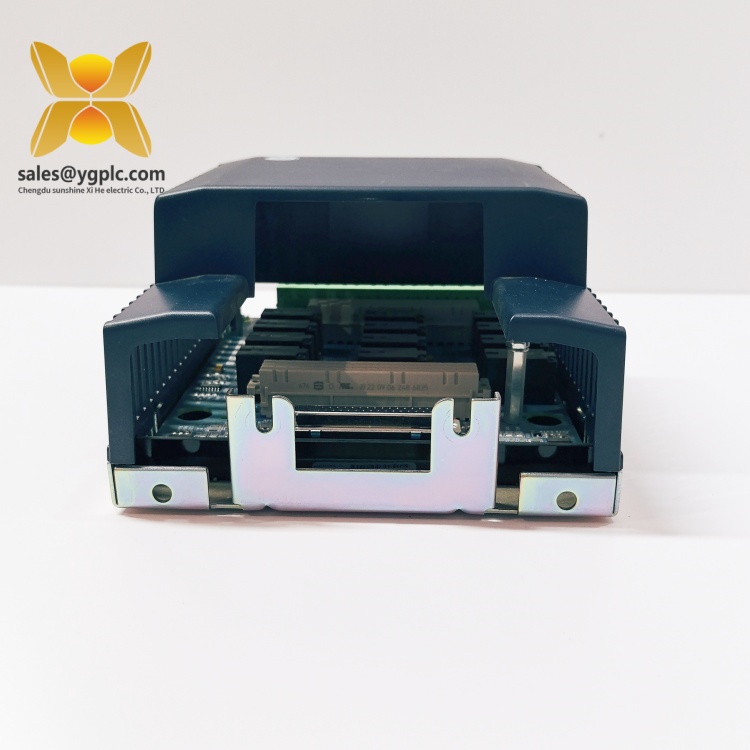

The GE IS400SRLYS2ABB is a high-performance relay output module designed for GE’s Speedtronic Mark VIe distributed control system, providing reliable and precise actuation of high-power industrial devices. As part of the IS400 Series, this module integrates seamlessly with Mark VIe controllers and I/O systems, enabling real-time control of solenoids, motor starters, and alarms in mission-critical environments. Engineered for rugged durability, the IS400SRLYS2ABB excels in power generation, oil & gas, and heavy manufacturing, where dependable switching of high-current signals is essential.

Featuring 8 Form-C relay output channels, the GE IS400SRLYS2ABB converts digital control signals from the Mark VIe controller into discrete outputs, supporting up to 250 V AC/30 V DC and 5 A per channel. Its galvanic isolation (2,500 Vrms) safeguards against voltage surges and electromagnetic interference (EMI), critical in high-power settings like offshore platforms and refineries. The module’s DIN-rail mounting design simplifies installation in compact control cabinets, while front-panel LED indicators provide real-time status updates for channel activity, power health, and fault conditions.

In the Mark VIe ecosystem, the IS400SRLYS2ABB interfaces directly with controllers such as the IS400AEBMH3A PLC controller and communication modules like the IS400TCASH1A terminal board, forming a robust control loop. Its hot-swappable design allows for module replacement without system shutdown, a key advantage for 24/7 operations in power plants and gas compression facilities. By combining high-channel density, advanced signal processing, and rugged construction, the IS400SRLYS2ABB ensures reliable automation and reduces maintenance costs in industrial processes.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS400SRLYS2ABB |

| Manufacturer | GE |

| Product Type | Relay Output Module |

| Series | Speedtronic Mark VIe |

| Channels | 8 Form-C relays (SPDT) |

| Contact Rating | 250 V AC/30 V DC, 5 A per channel |

| Isolation Rating | 2,500 Vrms |

| Response Time | <10 ms (activation/release) |

| Physical Dimensions | 167 mm (H) × 148 mm (W) × 55 mm (D) |

| Weight | 0.62 kg |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Mounting | DIN rail (35 mm standard) |

| Certifications | CE, UL 508, IEC 61131-2, MIL-STD-810G |

| Material | Flame-retardant polycarbonate (UL 94 V-0) |

Main Features and Advantages

High-Current Switching Capability:

The IS400SRLYS2ABB supports 5 A per channel for both AC and DC loads, making it suitable for controlling high-power devices like motor starters, solenoid valves, and contactors. Its Form-C relay configuration allows for flexible normally open (NO) or normally closed (NC) operation, adapting to diverse industrial requirements.

Galvanic Isolation for Signal Integrity:

With 2,500 Vrms galvanic isolation, the module protects the Mark VIe controller from transient voltages and EMI, critical in electrically noisy environments. This isolation prevents signal corruption and system downtime, ensuring reliable operation in power plants and offshore platforms where equipment must withstand extreme conditions.

Rugged Environmental Tolerance:

Compliant with MIL-STD-810G, the IS400SRLYS2ABB withstands extreme temperatures (-25°C to +60°C), vibration, and humidity. Conformal coating on the circuit board further protects against dust and moisture, making it suitable for corrosive offshore environments, desert power plants, and other harsh industrial settings.

Real-Time Diagnostics:

Front-panel LEDs provide instant visibility into channel status, power supply health, and fault conditions. For example, a steady green LED indicates a healthy channel, while a flashing red LED signals a fault requiring immediate attention. This feature reduces mean time to repair (MTTR) and optimizes maintenance schedules.

Hot-Swappable Design:

Facilitates module replacement without disrupting system operation, a key advantage for industries where downtime during maintenance can lead to significant production losses. This is particularly valuable in power generation and oil & gas sectors, where even short outages can impact operations.

Seamless Integration with Mark VIe:

The IS400SRLYS2ABB interfaces seamlessly with GE’s Mark VIe controllers and I/O modules via IONet, GE’s proprietary communication protocol. It also integrates with Cimplicity HMI software for centralized monitoring and control, enhancing operational efficiency by enabling real-time adjustments and data analysis.

Application Areas

The GE IS400SRLYS2ABB is ideally suited for industries requiring reliable high-current switching and control:

- Power Generation:

Controls turbine auxiliary systems (e.g., lube oil pumps, fuel valves) and generator breaker status in thermal, hydro, and nuclear power plants. Its high-current outputs ensure stable grid synchronization and efficient load sharing. - Oil & Gas:

Used in offshore platforms and refineries to manage emergency shutdown (ESD) systems, valve actuators, and compressor interlocks. The module’s rugged design ensures reliability in corrosive saltwater environments and high-vibration settings. - Heavy Manufacturing:

Supports robotics, conveyor systems, and process automation in automotive and chemical plants. Its 8-channel density simplifies integration of multiple high-power devices into a single control network, enabling centralized management of production lines. - Marine Propulsion:

Installed in naval vessels and commercial ships to monitor engine status, activate alarms, and control propulsion system parameters. The module’s isolation features protect against voltage spikes generated by onboard electrical systems.

Specific applications include gas turbine fuel valve control, refinery ESD system activation, and automotive assembly line conveyor speed regulation.

Related Products

- GE IS410SRLYS2A(Mark VIe Relay Output Module):

A higher-capacity variant with 12 relay channels, suitable for large-scale systems requiring more switching points. Shares the same DIN-rail mounting form factor as the IS400SRLYS2ABB. - GE IS400AEBMH3A(Mark VIe PLC Controller):

Works alongside the IS400SRLYS2ABB to provide centralized control and monitoring of relay outputs, leveraging the module’s IONet interface for real-time data exchange. - GE IS400TCASH1A(Mark VIe Terminal Board):

Connects field devices to the Mark VIe system, complementing the IS400SRLYS2ABB by consolidating wiring and ensuring secure signal transmission. - GE IS230TNPAH2A(Mark VIe DIO Module):

Integrates with the IS400SRLYS2ABB to create a hybrid I/O system, combining digital inputs/outputs with high-current relay outputs for comprehensive automation. - GE IS220PSCAH1A 336A4940CSP9(Mark VIe Power Supply Module):

Provides redundant 24 V DC power to the IS400SRLYS2ABB, ensuring uninterrupted operation in mission-critical systems. - GE IS200TDBTH1A(Mark Vle Terminal Board):

A legacy model compatible with older Mark Vle systems, serving as a replacement for aging installations requiring relay output functionality.

Installation and Maintenance

Pre-installation preparations:

Ensure the DIN rail is securely grounded and ventilated to prevent overheating. Verify the power supply meets the module’s 24 V DC requirements and use stranded copper wires (14–22 AWG) for connections. Configure the module’s address via GE’s Proficy software to ensure compatibility with the Mark VIe controller. Prior to installation, inspect the module for physical damage and confirm all components (e.g., terminal blocks, connectors) are included.

Maintenance suggestions:

Perform quarterly visual inspections of LED indicators to check for fault conditions, such as channel failures or power supply issues. Clean dust from vents biannually with compressed air, especially in dusty environments like cement plants or mining facilities. Replace relays every 50,000 operations or as needed to maintain switching reliability. Store spare IS400SRLYS2ABB modules in anti-static packaging at 10–30°C with <50% humidity, testing them annually to confirm functionality.

Product Guarantee

Our company offers a one-year quality warranty service for the IS400SRLYS2ABB, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. In addition, for discontinued models or urgent demands, relying on our global supply chain network, we can quickly respond to customers’ procurement needs for scarce spare parts, and provide reliable services to support the continuous and stable operation of industrial systems. As a leading import-export trade distribution company established in 2007 with 17 years of experience, we maintain large stocks of industrial control parts, including unpopular and discontinued models like the IS400SRLYS2ABB, ensuring timely access for our customers.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: