Description

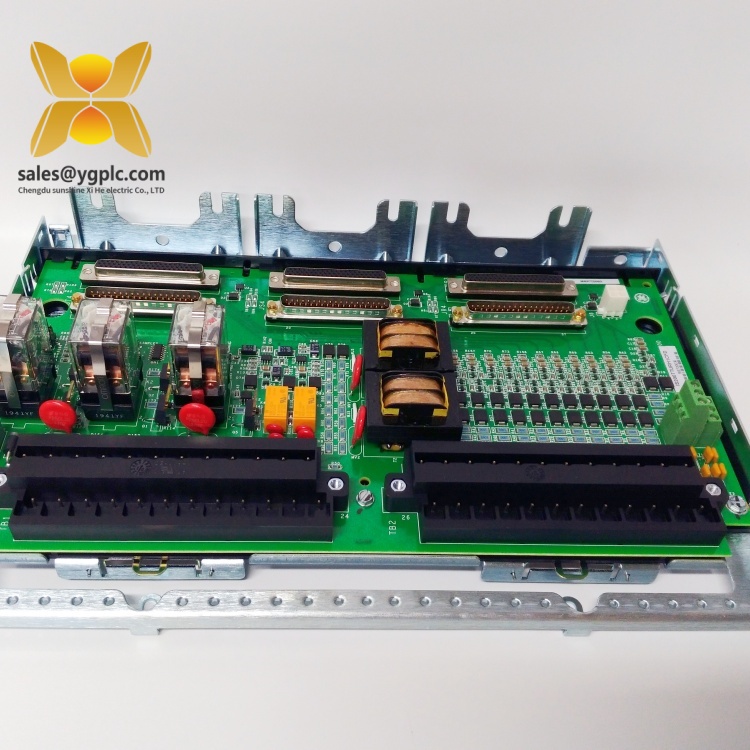

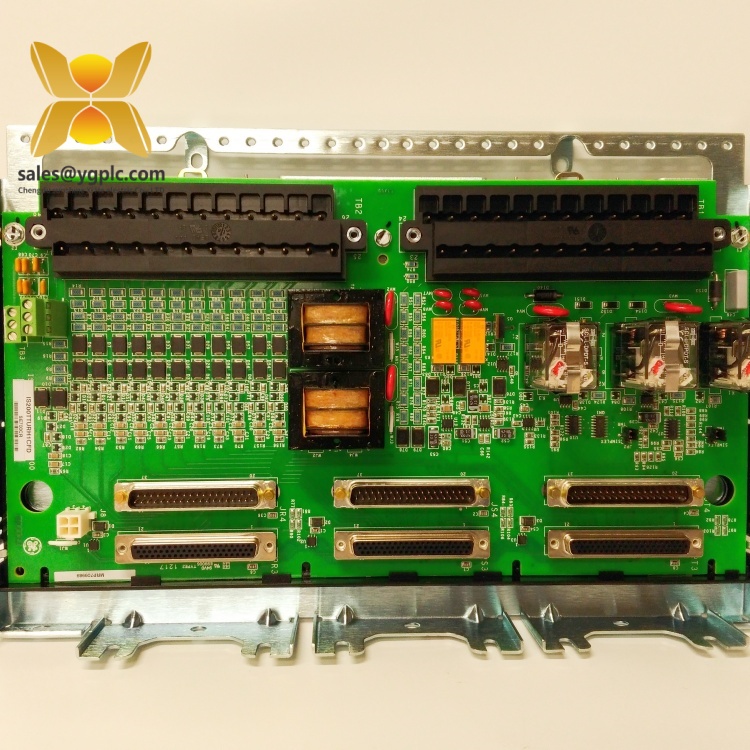

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS230TNRLH1B |

| Manufacturer | General Electric (GE) |

| Product Type | Relay Output Terminal Board |

| Output Channels | 8 relay outputs |

| Relay Rating | 250 VAC/10 A per channel |

| Control Voltage | 28 VDC ±5% |

| Physical Dimensions | 228 mm (H) × 102 mm (W) × 165 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Communication Interface | Dual 100 Mbps Ethernet (IONET protocol) |

| Isolation | 2500 Vrms between channels and ground |

| Certifications | CE, UL 508, IEC 61010-1, Class I Division 2 (with compatible enclosures) |

Main Features and Advantages

The GE IS230TNRLH1B delivers 8 relay outputs rated for 250 VAC/10 A, enabling direct control of high-power devices like turbine fuel valves, compressor anti-surge valves, and emergency shutdown (ESD) actuators. This capability eliminates the need for intermediate relays, reducing system complexity and potential failure points.

Dual 100 Mbps Ethernet ports with IONET protocol support ensure uninterrupted data transmission to the Mark VIe controller. In redundant architectures, automatic failover (<10 ms) maintains control continuity, critical for safety-critical systems where even brief communication loss could cause operational disruptions.

When paired with IS200STCIS1A terminal boards and explosion-proof enclosures, the GE IS230TNRLH1B meets Class I, Division 2 standards, making it suitable for oil refineries, chemical plants, and offshore platforms. Its 2500 Vrms isolation prevents sparking, mitigating ignition risks in explosive atmospheres.

A triple-layer conformal coating protects against salt spray, dust, and chemical vapors, while the module’s vibration resistance (10–2000 Hz, 10 G rms) ensures reliability in high-vibration environments like turbine halls. The wide operating temperature range (-30°C to +65°C) adapts to extreme climates, from arctic pipelines to desert power plants.

The GE IS230TNRLH1B supports hot swapping, allowing replacement without powering down the control system. This feature cuts mean time to repair (MTTR) to under 15 minutes, critical for maintaining uptime in mission-critical applications.

Application Areas

-

Power Generation:

- Controls gas turbine fuel supply valves, regulating flow rates during startup, shutdown, and load changes to optimize combustion efficiency.

- Actuates steam turbine bypass valves, diverting excess steam to condensers during grid fluctuations to prevent overpressure.

- Triggers generator circuit breakers in protection systems, isolating faults to safeguard equipment and grid stability.

-

Oil and Gas:

- Manages pipeline block valves via relay outputs, enabling remote shutdowns during leaks or pressure anomalies.

- Controls compressor anti-surge valves in offshore platforms, maintaining stable flow to prevent mechanical damage.

- Activates fire suppression systems in refineries, responding to heat detector signals with rapid valve actuation.

-

Manufacturing:

- Operates robotic welding arm relays in automotive plants, synchronizing motion with assembly line conveyors.

- Controls oven heating elements in food processing facilities, regulating temperatures via relay switching to ensure product quality.

-

Renewable Energy:

- Actuates wind turbine brake systems during high winds, feathering blades to reduce rotational speed and prevent structural stress.

- Switches solar inverter connections to battery storage systems, optimizing energy distribution during peak demand.

Related Products

- GE IS220PDIOH1B: Discrete I/O module that sends control signals to GE IS230TNRLH1B, coordinating relay actuation in turbine loops.

- GE IS200STCIS1A: Terminal board providing signal conditioning and isolation for GE IS230TNRLH1B in hazardous locations.

- GE IS220PPROS1B: Redundant power supply module delivering stable 28 VDC to GE IS230TNRLH1B, ensuring reliable relay operation.

- GE IS220VCMIH1A: Communication module that bridges GE IS230TNRLH1B with the Mark VIe controller, enabling remote monitoring.

- GE IS230TCISH6C: Discrete input terminal board that works with GE IS230TNRLH1B, providing status feedback for closed-loop control.

- GE IS200TTURH1CFD: Temperature monitoring module whose alerts trigger relay actions via GE IS230TNRLH1B in turbine protection systems.

- GE IS220PVIBH1A: Vibration sensor module that, when detecting anomalies, signals GE IS230TNRLH1B to actuate safety shutdowns.

Installation and Maintenance

Product Guarantee

GE IS215UCVEM09A VMIVME-017614-132 VMIVME-7698 | VMEbus Memory Module

GE IS215VCMIH2BB | VMEbus Communication Interface Card | IS215UCVHM06A IS200PMCIH1ACC

GE IS230SRTDH2A | RTD Input Module | IS230TDBTH6A

GE IS215VCMIH2BB | VMEbus Communication Interface Card | IS215UCVHM06A IS200PMCIH1ACC

GE IS215VCMIH2CA | VMEbus Communication Interface Card | IS200WETAH1AGC

GE IS215VPROH1BD | Emergency Turbine Protection Module | IS215VCMIH2CA

GE IS215WEPAH2B | Wind Energy Pitch Axis Controller Board | IS220PDIOH1A

GE IS215WETAH1BB | Mark VIe Ethernet Interface Module | IS220PDIAH1A 336A4940CSP1

GE IS200WETAH1AGC | Turbine Control Interface Module | IS200WETAH1AGC

GE IS220PDIIH1B 336A5026ADP1 | Digital Input Module | IS220PPROH1A

GE IS220PDIOH1A | Discrete Input/Output Pack for Industrial Control | IS220PPRFH1B

GE IS220PDIOH1B 336A5026ADP6 | Discrete Input/Output Pack for Industrial Control | IS220PPROS1B

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: