Description

GE IS230SRTDH2A Product Specification

Product Overview

The GE IS230SRTDH2A is a high-precision RTD (Resistance Temperature Detector) input module designed for GE’s Mark VIe Speedtronic Turbine Control System, specializing in real-time temperature monitoring of critical industrial equipment. Engineered to interface with platinum (Pt100) and nickel (Ni100) RTD sensors, this module delivers accurate temperature data for gas turbines, steam turbines, and rotating machinery in power generation, oil and gas, and heavy manufacturing.

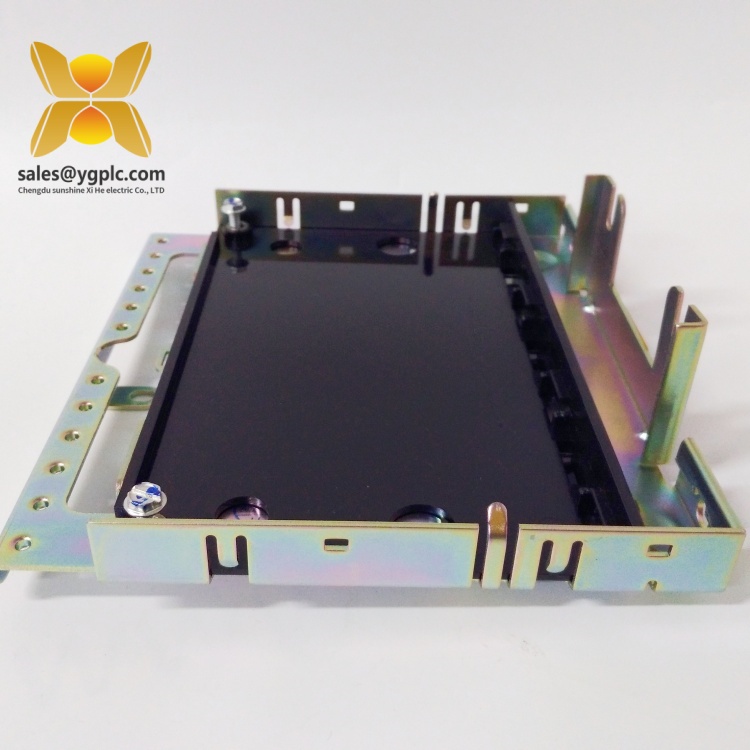

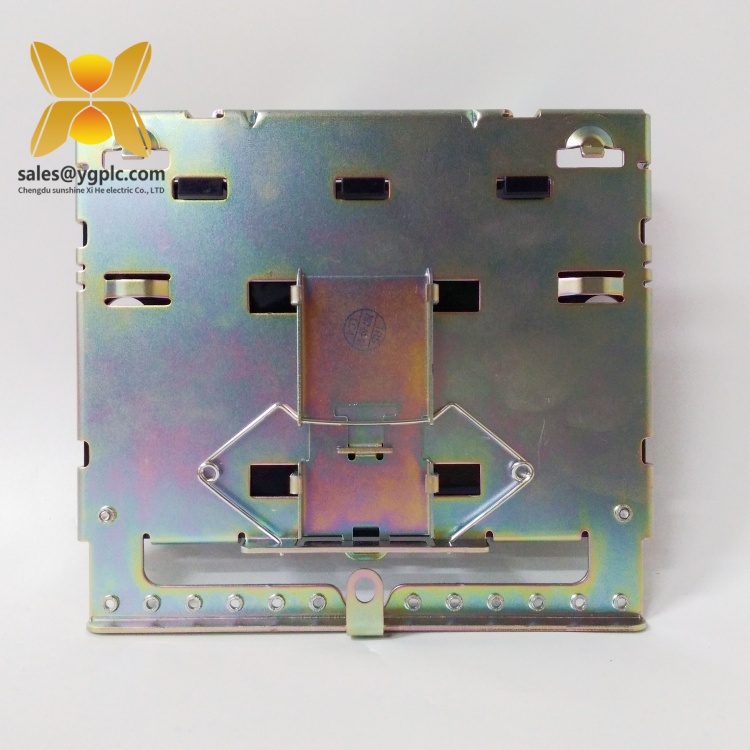

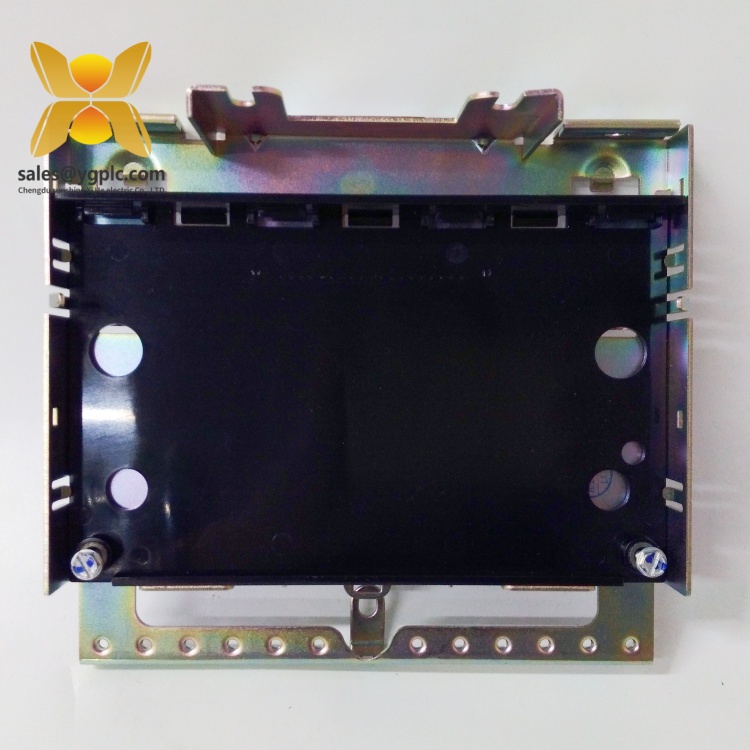

As part of the Mark VIe distributed control architecture, the GE IS230SRTDH2A supports 8 independent RTD channels, each capable of measuring temperatures ranging from -200°C to +850°C with ±0.1% accuracy 2. Its compact DIN-rail mounting design and Euroblock terminal connections simplify installation in space-constrained environments, while dual redundant 100 Mbps Ethernet ports ensure seamless data transmission to the Mark VIe controller. The module’s rugged construction—featuring a triple-layer conformal coating and IP20-rated enclosure—ensures reliable operation in harsh conditions with high vibration, humidity, and temperature fluctuations (-30°C to +65°C) 2.

In automation systems, the GE IS230SRTDH2A acts as the cornerstone for temperature control loops, providing critical data for turbine bearing monitoring, heat exchanger optimization, and early fault detection. Its compatibility with PRTD/VRTD I/O processors and IS200SRTDH2ACB terminal boards enables deployment in hazardous locations, adhering to industry standards for safety and reliability 2.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS230SRTDH2A |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Input Module |

| Series | Mark VIe Speedtronic Turbine Control System |

| Input Channels | 8-channel (RTD sensors: Pt100, Ni100) |

| Temperature Range | -200°C to +850°C |

| Accuracy | ±0.1% full scale |

| Resolution | 0.1°C |

| Excitation Current | 1 mA (constant current source) |

| Communication Interface | Dual 100 Mbps Ethernet ports (IONET protocol) |

| Physical Dimensions | 100 mm (H) × 132 mm (W) × 57 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Power Supply | 24 VDC ±5%, 50 mA |

| Certifications | CE, UL 61010-1 (compliant with industrial automation standards) |

Main Features and Advantages

High-Accuracy Temperature Monitoring:

The GE IS230SRTDH2A supports 8 channels for simultaneous RTD measurements, with ±0.1% accuracy across a wide temperature range. This precision is critical for detecting subtle temperature variations in turbine bearings, ensuring optimal lubrication and preventing overheating 2.

The GE IS230SRTDH2A supports 8 channels for simultaneous RTD measurements, with ±0.1% accuracy across a wide temperature range. This precision is critical for detecting subtle temperature variations in turbine bearings, ensuring optimal lubrication and preventing overheating 2.

Redundant Communication Architecture:

Dual Ethernet ports ensure uninterrupted data transmission to the Mark VIe controller, with automatic failover in <10 ms. This redundancy minimizes downtime risks in safety-critical systems, such as turbine shutdowns triggered by 异常温度 spikes 2.

Dual Ethernet ports ensure uninterrupted data transmission to the Mark VIe controller, with automatic failover in <10 ms. This redundancy minimizes downtime risks in safety-critical systems, such as turbine shutdowns triggered by 异常温度 spikes 2.

Hazardous Location Compliance:

Rated for Class I, Division 2 environments, the module is suitable for use in explosive atmospheres common in oil refineries and chemical plants. When paired with IS200SRTDH2ACB terminal boards, it provides intrinsic safety barriers, ensuring compliance with ATEX and IECEx standards 2.

Rated for Class I, Division 2 environments, the module is suitable for use in explosive atmospheres common in oil refineries and chemical plants. When paired with IS200SRTDH2ACB terminal boards, it provides intrinsic safety barriers, ensuring compliance with ATEX and IECEx standards 2.

Rugged Industrial Design:

A triple-layer conformal coating protects against dust, moisture, and chemical exposure, while the module’s vibration resistance (10–2000 Hz, 10 G rms) and wide operating temperature range make it suitable for offshore platforms, power plants, and other harsh industrial settings 2.

A triple-layer conformal coating protects against dust, moisture, and chemical exposure, while the module’s vibration resistance (10–2000 Hz, 10 G rms) and wide operating temperature range make it suitable for offshore platforms, power plants, and other harsh industrial settings 2.

Hot-Swappable Operation:

The GE IS230SRTDH2A supports hot swapping, allowing replacement of a faulty unit without powering down the control system. This feature reduces mean time to repair (MTTR) to under 15 minutes, critical for maintaining uptime in mission-critical applications 2.

The GE IS230SRTDH2A supports hot swapping, allowing replacement of a faulty unit without powering down the control system. This feature reduces mean time to repair (MTTR) to under 15 minutes, critical for maintaining uptime in mission-critical applications 2.

Application Areas

-

Power Generation:

- Monitors turbine bearing temperatures to detect early signs of mechanical wear, preventing catastrophic failures in combined cycle plants.

- Optimizes steam turbine efficiency by analyzing temperature gradients in heat exchangers.

-

Oil and Gas:

- Supports compressor train temperature monitoring in offshore platforms, providing real-time data to optimize maintenance schedules and prevent unplanned shutdowns.

- Measures pipeline pump temperatures to ensure compliance with safety standards in remote locations.

-

Manufacturing:

- Regulates robotic arm temperatures in automotive assembly lines to maintain precision and reduce production errors.

- Monitors conveyor belt motor temperatures in food processing facilities to ensure continuous operation and product quality.

-

Renewable Energy:

- Tracks wind turbine gearbox temperatures to enable predictive maintenance and extend component lifespan.

- Measures solar panel inverter temperatures to optimize energy production in utility-scale solar farms.

Related Products

- GE PRTD/VRTD I/O Processor: Integrates with the IS230SRTDH2A to process RTD signals and communicate with the Mark VIe controller.

- GE IS200SRTDH2ACB: Terminal board compatible with IS230SRTDH2A, providing signal conditioning and isolation for hazardous locations.

- GE IS220PPROS1B: Redundant power supply module that powers the IS230SRTDH2A, ensuring stable operation in mission-critical systems.

- GE IS220VCMIH1A: Communication module ensuring seamless data transmission between IS230SRTDH2A and the Mark VIe controller.

- GE IS220PAICH1A: Analog input module used alongside IS230SRTDH2A to handle additional process variables like pressure and vibration.

- GE IS220PVIBH1A: Vibration monitoring module often deployed with IS230SRTDH2A for comprehensive machinery health assessment.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS230SRTDH2A, verify the input voltage matches the module’s requirements (24 VDC ±5%) and ensure the control cabinet is properly grounded to prevent electrostatic discharge (ESD). Use an ESD wrist strap during handling. Mount the module on a DIN rail with at least 20 mm clearance for airflow, securing it with anti-vibration brackets to minimize mechanical stress. Connect the IS200SRTDH2ACB terminal board to the module, ensuring proper wiring for RTD inputs and Ethernet links to the Mark VIe controller

Before installing the GE IS230SRTDH2A, verify the input voltage matches the module’s requirements (24 VDC ±5%) and ensure the control cabinet is properly grounded to prevent electrostatic discharge (ESD). Use an ESD wrist strap during handling. Mount the module on a DIN rail with at least 20 mm clearance for airflow, securing it with anti-vibration brackets to minimize mechanical stress. Connect the IS200SRTDH2ACB terminal board to the module, ensuring proper wiring for RTD inputs and Ethernet links to the Mark VIe controller

Maintenance Recommendations:

Perform monthly visual inspections to confirm front-panel LEDs (Power, Ethernet Link, Fault) indicate normal operation. Clean dust from ventilation slots using compressed air to maintain cooling efficiency. Quarterly, use a multimeter to verify output voltage (24 VDC ±5%) and check terminal connections for corrosion. Annually, update firmware via GE’s Proficy software to access bug fixes and compatibility enhancements. Test redundancy by disconnecting one Ethernet port and confirming seamless switchover to the secondary channel

Perform monthly visual inspections to confirm front-panel LEDs (Power, Ethernet Link, Fault) indicate normal operation. Clean dust from ventilation slots using compressed air to maintain cooling efficiency. Quarterly, use a multimeter to verify output voltage (24 VDC ±5%) and check terminal connections for corrosion. Annually, update firmware via GE’s Proficy software to access bug fixes and compatibility enhancements. Test redundancy by disconnecting one Ethernet port and confirming seamless switchover to the secondary channel

Product Warranty

Our company offers a one-year quality warranty for the GE IS230SRTDH2A, covering hardware malfunctions not caused by human factors. During the warranty period, if the module exhibits abnormal temperature readings, communication failures, or functional defects, we will provide replacement services. For discontinued models or urgent demands, our global supply chain network ensures rapid fulfillment of scarce spare parts, supporting the continuous operation of your industrial systems. As a leading import-export distributor with 17 years of experience, we maintain large inventories of industrial control parts, including hard-to-find models, to meet your urgent needs 2.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: