Description

GE IS220PTURH1A Turbine Control Module

Product Overview:GE IS220PTURH1A

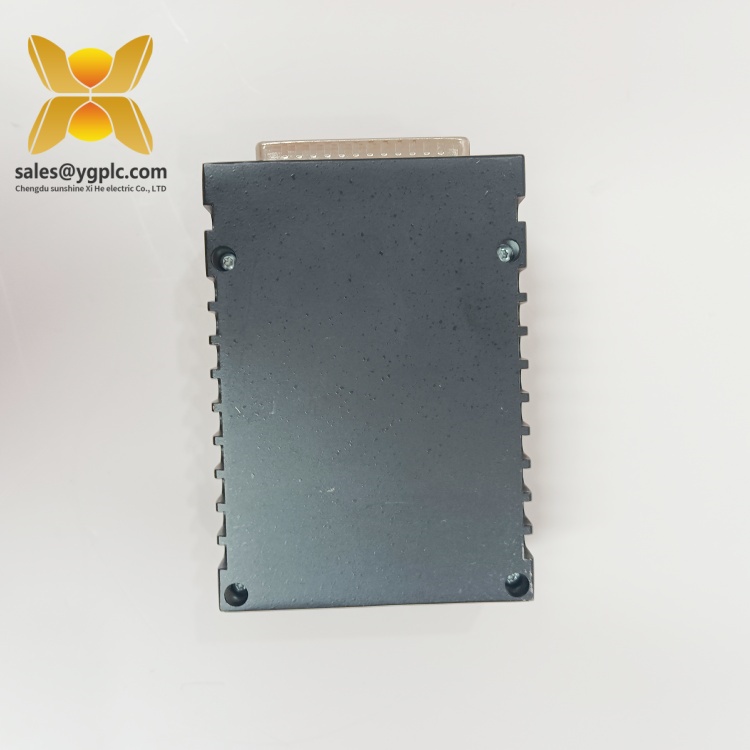

The GE IS220PTURH1A turbine control module is a high-precision industrial automation component designed for advanced control and monitoring of gas and steam turbines in critical power generation and process industries. As a core part of GE’s Mark VIe Speedtronic control system, this module integrates seamlessly with the platform’s architecture to deliver real-time data processing, closed-loop control, and safety interlock functions. Engineered to meet the rigorous demands of rotating machinery management, the IS220PTURH1A ensures optimal turbine performance, efficiency, and reliability in mission-critical applications.

Featuring a robust design, the IS220PTURH1A supports multiple control algorithms, including speed control, load sharing, and surge prevention, making it suitable for complex turbine systems. It accepts inputs from various sensors (e.g., temperature, pressure, vibration) and converts them into actionable control signals for actuators and valves. The module’s 24V DC power supply and dual redundant communication channels (Ethernet/IP and Modbus) ensure stable operation even in harsh industrial environments. As a key component of the Mark VIe system, the IS220PTURH1A plays a pivotal role in enabling predictive maintenance, reducing downtime, and enhancing overall plant productivity.

The IS220PTURH1A is designed for scalability, allowing integration with other Mark VIe modules (e.g., I/O cards, communication gateways) to form a comprehensive control solution. Its compact form factor (140mm x 100mm x 50mm) and DIN rail mounting capability facilitate easy installation in control cabinets, while its rugged construction (IP20 protection rating) ensures resistance to dust, moisture, and electromagnetic interference. By providing precise turbine control and real-time diagnostics, the IS220PTURH1A helps industries meet regulatory standards and optimize energy output.

Technical Specifications:GE IS220PTURH1A

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PTURH1A |

| Manufacturer | GE |

| Product Type | Turbine Control Module |

| Input Voltage | 24V DC ±10% |

| Communication Protocols | Ethernet/IP, Modbus RTU |

| Physical Dimensions | 140mm (H) x 100mm (W) x 50mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to 70°C |

| Humidity Resistance | 5–95% non-condensing |

| Mounting Type | DIN rail |

| Country of Origin | United States |

| Redundancy | Dual channel redundancy |

GE IS220PTURH1A

Main Features and Advantages:GE IS220PTURH1A

Advanced Turbine Control Algorithms: The IS220PTURH1A incorporates pre-programmed control strategies for speed regulation, load sharing, and anti-surge protection, ensuring stable turbine operation across varying loads. Its real-time data processing capabilities enable precise adjustments to fuel flow, steam valves, and excitation systems, optimizing energy efficiency and reducing wear on mechanical components.

Robust Redundancy Design: With dual redundant communication channels and power inputs, the module minimizes the risk of downtime by automatically switching to backup systems in the event of a primary component failure. This feature is critical for applications where continuous operation is non-negotiable, such as power plants and offshore platforms.

Compact and Industrial-Grade Construction: The module’s compact design (140mm x 100mm x 50mm) maximizes space efficiency in control panels, while its IP20-rated enclosure protects against environmental contaminants. The rugged PCB design and high-quality components ensure reliable performance in high-vibration and high-temperature environments, typical of industrial turbine setups.

Seamless System Integration: As part of the Mark VIe ecosystem, the IS220PTURH1A integrates effortlessly with GE’s IS210BPPCH1ACA I/O processors and IS220PAOCH1A analog output modules, forming a cohesive control network. Its support for industry-standard protocols (Ethernet/IP, Modbus) also allows integration with third-party SCADA systems and cloud-based analytics platforms.

Proactive Diagnostic Capabilities: Built-in self-diagnostic functions and LED indicators provide real-time visibility into module health, enabling operators to identify issues such as communication errors or sensor malfunctions. This proactive approach to maintenance reduces troubleshooting time and supports predictive maintenance strategies.

GE IS220PTURH1A

Application Areas:GE IS220PTURH1A

The GE IS220PTURH1A turbine control module is widely deployed in industries requiring precise control and monitoring of high-value turbine assets:

- Power Generation: In thermal, combined-cycle, and renewable energy plants, the module manages gas and steam turbines to ensure stable power output and grid synchronization. It optimizes fuel consumption, monitors turbine health, and enforces safety interlocks to prevent overspeeding or overload conditions.

- Oil and Gas: Used in compressor stations and refineries, the IS220PTURH1A controls steam turbines driving pumps and compressors, ensuring efficient fluid handling and process stability. Its redundancy features are critical for uninterrupted operation in offshore and remote locations.

- Industrial Manufacturing: In facilities using steam turbines for power generation or process heating, the module ensures reliable operation of boilers and turbines, supporting continuous production lines in sectors like chemicals, pulp and paper, and metallurgy.

- Cogeneration Systems: The module optimizes combined heat and power (CHP) systems by balancing power generation and thermal energy output, enhancing overall energy efficiency in commercial and industrial applications.

- Marine Applications: Deployed in shipboard turbine systems, the IS220PTURH1A provides precise control for propulsion and auxiliary power, meeting the rigorous demands of marine environments.

GE IS220PTURH1A

Related Products:GE IS220PTURH1A

- IS210BPPCH1ACA: A Mark VIe I/O processor that works alongside the IS220PTURH1A to manage analog and digital signals, supporting triple modular redundancy (TMR) for high-integrity applications.

- IS220PAOCH1A: An analog output module that converts control signals from the IS220PTURH1A into voltage/current outputs for actuators and valves, ensuring precise process control.

- IS200ADIIH1A: A dual-channel I/O module that expands the system’s sensor and actuator connectivity, compatible with the IS220PTURH1A for the integration of additional monitoring points.

- IS420ESWBH3AE: A managed Ethernet switch that enhances network connectivity for the IS220PTURH1A, enabling high-speed data transfer and remote diagnostics in distributed control systems.

- IS410SRLYS2A: A solid-state relay module that provides fail-safe switching for high-power circuits, complementing the IS220PTURH1A in safety-critical applications.

- IS200AEPCH1AB: A redundant power supply module that ensures stable power delivery to the IS220PTURH1A and other Mark VIe components, mitigating risks from power fluctuations.

Installation and Maintenance:GE IS220PTURH1A

Pre-installation Preparations:

Before installing the IS220PTURH1A, verify that the control cabinet meets environmental requirements (temperature, humidity, and EMI protection). Ensure the DIN rail is securely mounted and grounded, then align the module with the rail and fasten it using the provided clips. Connect the 24V DC power supply to the terminal block, ensuring correct polarity, and link the module to the control network via Ethernet or Modbus cables. Validate all connections using GE’s ToolboxST software to confirm proper communication and configuration.

Before installing the IS220PTURH1A, verify that the control cabinet meets environmental requirements (temperature, humidity, and EMI protection). Ensure the DIN rail is securely mounted and grounded, then align the module with the rail and fasten it using the provided clips. Connect the 24V DC power supply to the terminal block, ensuring correct polarity, and link the module to the control network via Ethernet or Modbus cables. Validate all connections using GE’s ToolboxST software to confirm proper communication and configuration.

Maintenance Recommendations:

Regular maintenance is essential to sustain the IS220PTURH1A’s performance. Conduct quarterly inspections to check for loose connections, damaged cables, or overheating. Clean the module’s vents with compressed air to prevent dust accumulation, which can affect heat dissipation. Annually, perform firmware updates using GE’s official software to access new features and security patches. Test the redundancy functionality by simulating a primary channel failure to ensure seamless failover. If replacing the module, use a pre-configured spare to minimize downtime and ensure compatibility with the existing system setup.

Regular maintenance is essential to sustain the IS220PTURH1A’s performance. Conduct quarterly inspections to check for loose connections, damaged cables, or overheating. Clean the module’s vents with compressed air to prevent dust accumulation, which can affect heat dissipation. Annually, perform firmware updates using GE’s official software to access new features and security patches. Test the redundancy functionality by simulating a primary channel failure to ensure seamless failover. If replacing the module, use a pre-configured spare to minimize downtime and ensure compatibility with the existing system setup.

GE IS220PTURH1A

Product Warranty:GE IS220PTURH1A

Our company offers a 12-month quality warranty for the GE IS220PTURH1A turbine control module, covering non-human-induced hardware defects. In the event of performance issues or functional failures during the warranty period, we provide prompt replacement services to restore system integrity. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce components, supporting uninterrupted operation of industrial systems.

With 17 years of expertise in industrial control distribution, we prioritize reliability and customer support, offering competitive pricing and technical assistance for installation, configuration, and troubleshooting. The IS220PTURH1A exemplifies our commitment to delivering high-quality, innovative solutions that empower industries to achieve operational excellence. Contact us today to explore how this module can enhance your turbine control infrastructure.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for official technical documentation. Always refer to GE’s manuals for detailed specifications and safety guidelines.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: