Description

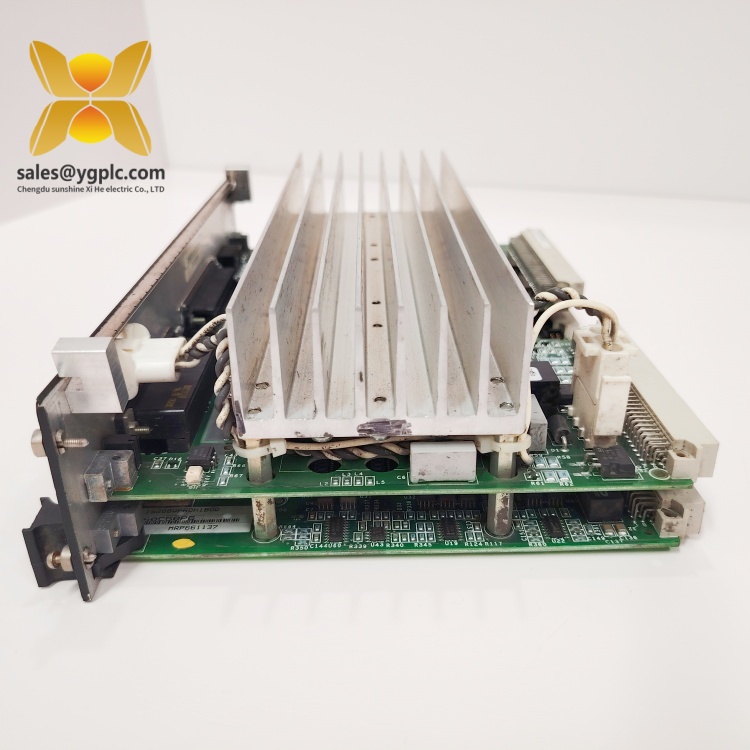

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS215VPROH2BC |

| Manufacturer | General Electric (GE) |

| Product Type | Servo Motor Drive Module (Dual-Axis) |

| Control Technology | Virtual Pro Servo (VPRO) with 20-bit encoder support |

| Communication Protocols | EtherNet/IP, Profibus, RS-485 |

| Power Supply | 24–48 VDC (control), 100–240 VAC (motor) |

| Physical Dimensions | 177.8 mm (H) × 101.6 mm (W) × 254 mm (D) |

| Weight | 2.3 kg |

| Axis Capacity | 2 independent axes |

| Encoder Resolution | Up to 1,048,576 pulses per revolution (20-bit) |

| Operating Temperature | -40°C to +70°C |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Certifications | CE, UL, CSA |

VPROH2B IS215VPROH2BC

Main Features and Advantages

Advanced Diagnostics: Real-time diagnostic tools monitor motor health, power supply stability, and communication integrity, with fault alerts transmitted via the control system’s HMI or front-panel LEDs. The module also stores detailed fault logs for post-event analysis, enabling proactive maintenance and reducing mean time to repair (MTTR).

VPROH2B IS215VPROH2BC

Application Areas

-

Manufacturing and Robotics:

- Pick-and-Place Systems: Controls robotic arms in electronics assembly lines, ensuring precise component placement with sub-millimeter accuracy.

- Packaging Machinery: Manages conveyor belts and labeling systems, synchronizing motor speeds for consistent product flow and packaging quality.

-

Semiconductor and Electronics:

- Wafer Handling: Powers automated stages in lithography and inspection equipment, requiring ultra-smooth motion to avoid damage to delicate wafers.

- PCB Fabrication: Drives spindle motors in drilling and routing machines, maintaining high-speed rotation with minimal vibration.

-

Aerospace and Defense:

- Assembly Lines: Supports the precise positioning of components in aircraft manufacturing, such as wing flap actuators or engine part alignment.

- Testing Equipment: Controls servo-driven test stands for evaluating the performance of aerospace actuators and valves.

-

Medical Device Production:

- Syringe Filling Machines: Ensures accurate piston movement in pharmaceutical filling lines, meeting strict regulatory requirements for dose consistency.

- Lab Automation: Drives microplate handlers and liquid dispensers in high-throughput screening systems, requiring rapid and precise motion.

Related Products

- GE IS215VPROH1BA: A single-axis variant of the GE IS215VPROH2BC, suitable for simpler motion control applications where dual-axis capability is unnecessary.

- GE IS215UCVEM1A: A universal I/O module for PACSystems RX3i, providing analog and digital signals to complement the GE IS215VPROH2BC in hybrid control systems.

- GE IC695CPU320: A high-performance CPU module for PACSystems RX3i, offering enhanced processing power for complex multi-axis control algorithms when paired with the GE IS215VPROH2BC.

- GE IS215TRDB1B: A terminal block adapter for the GE IS215VPROH2BC, simplifying wiring connections for motor power and feedback signals.

- GE IS215VPLCH1A: A linear servo drive module designed for direct drive motors, providing an alternative for applications requiring linear motion instead of rotational.

VPROH2B IS215VPROH2BC

Installation and Maintenance

Before installing the GE IS215VPROH2BC, ensure the following:

- Verify the control power supply (24–48 VDC) and motor power supply (100–240 VAC) are within specified ranges and properly grounded to prevent EMI issues.

- Use GE’s Proficy Machine Edition software to configure motor parameters (e.g., encoder type, current limits) and network settings before mounting the module in the RX3i rack.

- Ensure adequate airflow around the module to prevent overheating, especially in multi-module configurations.

- Routine Inspections: Monthly checks of front-panel LEDs to confirm normal operation (e.g., green “Power” and “Ready” indicators). Clean dust from ventilation slots using compressed air to maintain optimal cooling.

- Encoder Calibration: Annually verify encoder accuracy using a precision gauge, adjusting parameters in the software if deviations exceed tolerance.

- Firmware Updates: Periodically update the module’s firmware via Proficy software to access new features or resolve compatibility issues with newer control system versions.

- Cable Integrity Check: Quarterly inspection of motor power and feedback cables for signs of wear or loose connections, particularly in high-vibration environments.

VPROH2B IS215VPROH2BC

Product Warranty

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This product description is based on technical data derived from GE’s official specifications and industry applications. For detailed operational guidelines, refer to the GE IS215VPROH2BC user manual or contact our technical support team for personalized assistance.

GE IS200TSVCH1ADC S1CX01H AI/AO/DI/DO module

GE IS200TTURH1CCC S1DF00Z Servo valve

GE IS200TRLYH1BGF Analog input

GE IS220PAICH1B Digital output

GE IS220PDOAH1A Program module

GE IC695CPU320-CF Ethernet

GE IC687BEM731-AB Integrated protection device

GE IC698CHS009A Connecting module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: