Description

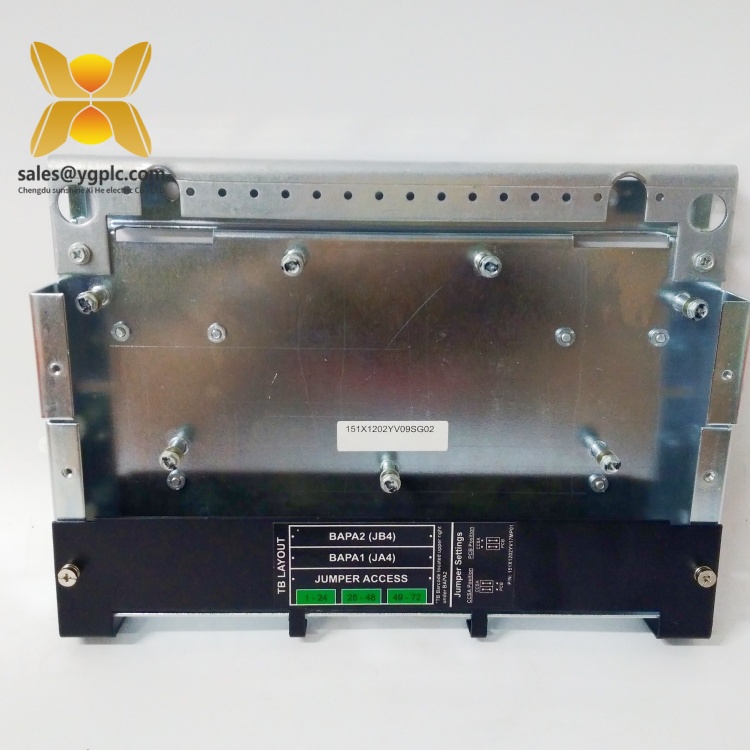

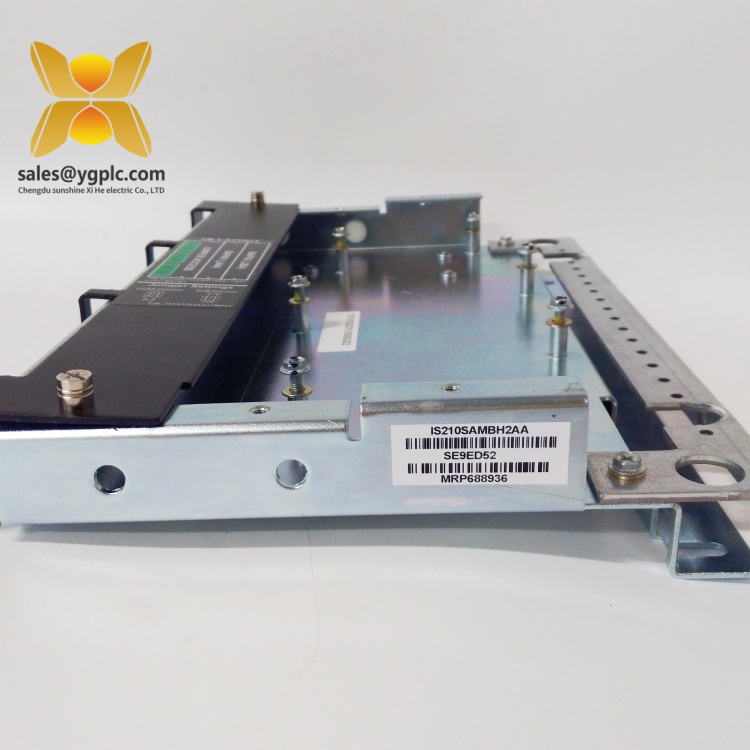

GE IS210SAMBH2AA Analog Input Module

Product Overview: GE IS210SAMBH2AA

The GE IS210SAMBH2AA analog input module is a high-precision industrial component designed for GE’s Mark VIe Turbine Control System, a leading platform for steam and gas turbine automation. As a critical component of this system, the IS210SAMBH2AA converts analog signals from sensors and transducers into digital data for real-time monitoring and control, enabling precise turbine performance optimization. Engineered for mission-critical power generation applications, this module integrates advanced signal conditioning with rugged hardware to ensure reliable operation in harsh industrial environments.

Featuring 8 isolated analog input channels, the IS210SAMBH2AA supports multiple signal types (4–20 mA, 0–10 V DC) with high-resolution 16-bit analog-to-digital conversion, ensuring accurate measurement of parameters like temperature, pressure, and flow. Its hot-swappable design allows maintenance without system shutdown, while the -40°C to +70°C operating range and IP20 protection rating make it suitable for demanding settings, from power plant control rooms to offshore platforms. The module’s dual redundant power inputs and built-in self-diagnostic functions enhance system reliability, reducing unplanned downtime in critical operations.

Within automation architectures, the IS210SAMBH2AA acts as a frontline data acquisition component, feeding real-time process variables to the Mark VIe control processor for analysis. Its compatibility with GE’s Mark VIe I/O racks (e.g., IS200TBRCH1B) and compliance with IEEE 1131-2 standards solidifies its role in power generation systems where precision and durability are non-negotiable.

Technical Specifications: GE IS210SAMBH2AA

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210SAMBH2AA |

| Manufacturer | GE |

| Product Type | Analog Input Module |

| Input Channels | 8 channels (isolated) |

| Signal Types | 4–20 mA, 0–10 V DC |

| Resolution | 16-bit ADC |

| Accuracy | ±0.1% of full scale |

| Power Supply | 24V DC (dual redundant) |

| Physical Dimensions | 150 mm (H) × 100 mm (W) × 50 mm (D) |

| Weight | 1.0 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (Mark VIe system) |

| Compliance | IEEE 1131-2, IEC 61131-3 |

| Country of Origin | United States |

Main Features and Advantages: GE IS210SAMBH2AA

High-Precision Signal Conditioning: The IS210SAMBH2AA ensures accurate conversion of analog signals with 16-bit resolution, critical for precise turbine performance monitoring. Its built-in filtering reduces noise interference, enabling reliable data acquisition in electrically noisy environments.

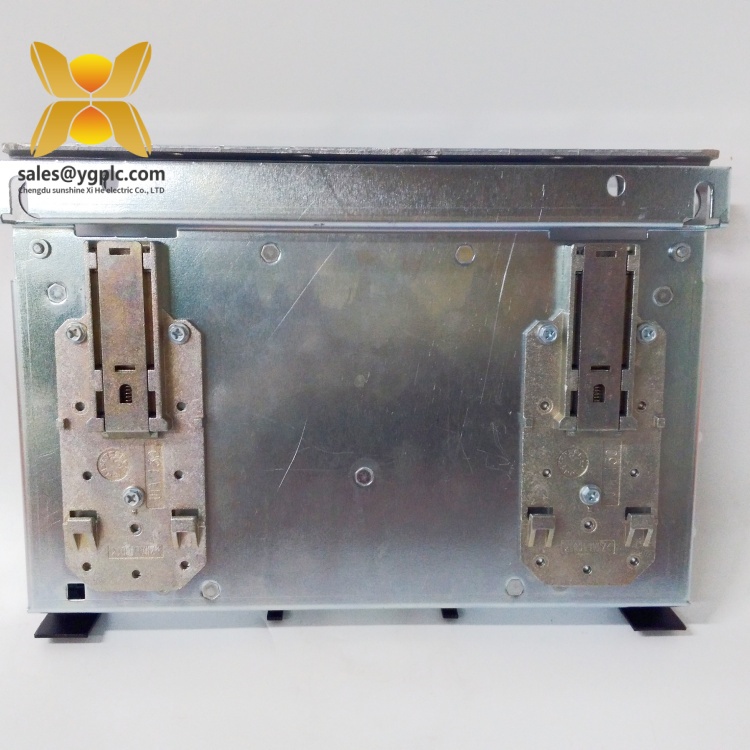

Redundant and Rugged Design: Dual redundant power inputs and a rugged metal enclosure protect against power fluctuations and environmental stress, while the hot-swappable design allows module replacement without system disruption—essential for 24/7 operations in power plants.

Wide Signal Compatibility: Support for multiple analog signal types eliminates the need for external converters, simplifying system integration and reducing hardware costs. This flexibility makes it suitable for diverse sensor setups in turbine control applications.

Advanced Diagnostics: Built-in self-diagnostic functions continuously monitor module health, providing real-time feedback on channel status and fault conditions. This proactive feature minimizes troubleshooting time and enhances system maintainability.

Environmental Resilience: With an extended temperature range and robust construction, the module withstands harsh industrial conditions, including vibration, dust, and temperature extremes, ensuring long-term reliability in critical infrastructure.

Application Areas: GE IS210SAMBH2AA

The GE IS210SAMBH2AA analog input module is pivotal in industries requiring precise turbine control and process monitoring:

- Power Generation: Measures key parameters (temperature, pressure, flow) in steam and gas turbines for thermal, combined-cycle, and renewable energy plants, enabling optimal power output and safety interlocks.

- Oil and Gas: Monitors process variables in turbine-driven compressors and pumps for offshore platforms and refineries, supporting remote operations in harsh, corrosive environments.

- Industrial Manufacturing: Integrates with turbine systems in chemical plants, paper mills, and cement facilities to optimize energy consumption and process efficiency.

- District Energy: Controls steam turbines in district heating networks, ensuring reliable heat distribution for commercial and residential applications through precise analog data acquisition.

Related Products: GE IS210SAMBH2AA

- GE IS210MCCPH1A Digital I/O Module: Complements the IS210SAMBH2AA by processing digital signals for comprehensive turbine control.

- GE IS200TCCPH1A Turbine Control Processor: The central CPU module that communicates with the IS210SAMBH2AA to execute control algorithms.

- GE IS210PARPH1A Power Supply Module: Provides redundant power to the IS210SAMBH2AA and other Mark VIe components for continuous operation.

- GE IS210MATBH1AA Communication Module: Enables network connectivity for the IS210SAMBH2AA, supporting data transmission to supervisory systems.

- GE IS210SCMBH2AA Signal Conditioning Module: Enhances signal quality for the IS210SAMBH2AA in high-noise industrial environments.

- GE IS200TBRCH1B I/O Rack: Houses the IS210SAMBH2AA and other Mark VIe modules, providing mechanical support and power distribution.

Installation and Maintenance: GE IS210SAMBH2AA

Pre-installation Preparations:

Before installing the IS210SAMBH2AA, verify the control rack is properly grounded and the power supply (24V DC) matches specifications. Clean the rack slot and secure the module using the provided brackets, ensuring alignment with the backplane connectors. Connect analog sensor cables to the terminal block, following GE’s wiring diagram to prevent signal interference. Terminate redundant power inputs and configure channel settings (signal type, scaling) via the module’s front-panel interface or remote configuration software.

Before installing the IS210SAMBH2AA, verify the control rack is properly grounded and the power supply (24V DC) matches specifications. Clean the rack slot and secure the module using the provided brackets, ensuring alignment with the backplane connectors. Connect analog sensor cables to the terminal block, following GE’s wiring diagram to prevent signal interference. Terminate redundant power inputs and configure channel settings (signal type, scaling) via the module’s front-panel interface or remote configuration software.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks for loose connections, damaged cables, or abnormal LED indicators. Use a multimeter to verify input signal integrity and module power supply stability.

- Diagnostic Testing: Quarterly run built-in self-diagnostic routines to identify channel anomalies or hardware degradation. Reference GE’s diagnostic codes for prompt issue resolution.

- Environmental Monitoring: Regularly assess ambient temperature and humidity to ensure they fall within specified limits, installing additional cooling if necessary to prevent overheating.

- Spare Parts Management: Keep a spare IS210SAMBH2AA on hand, leveraging our global supply chain for rapid replacement of discontinued or urgent components to minimize downtime.

Product Guarantee: GE IS210SAMBH2AA

Our company provides a 12-month quality warranty for the GE IS210SAMBH2AA analog input module, covering non-human-induced hardware defects. During the warranty period, we will replace any module with signal processing errors, power supply failures, or physical damage at no cost. For urgent needs or discontinued models, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing disruptions to your critical operations.

With 17 years of expertise in industrial control distribution, we are committed to reliable products and exceptional service. The IS210SAMBH2AA exemplifies our dedication to quality, offering precise analog data acquisition for turbine control systems. Contact us today to optimize your automation infrastructure with this robust module.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for GE’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IC660ELB921M Data acquisition module

GE IC660ELD100A probe

GE IC660EPM100J Tachometer sensor

GE IC660TBA026 modbus card

GE IC660TBA026 Acquisition card

GE SR469 469-P5-HI-A20-E redundancy

GE IS220PDIAH1A Network communication

GE IC697ALG320 Digital relay output module

GE IC697ALG440 Output module digit

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: