Description

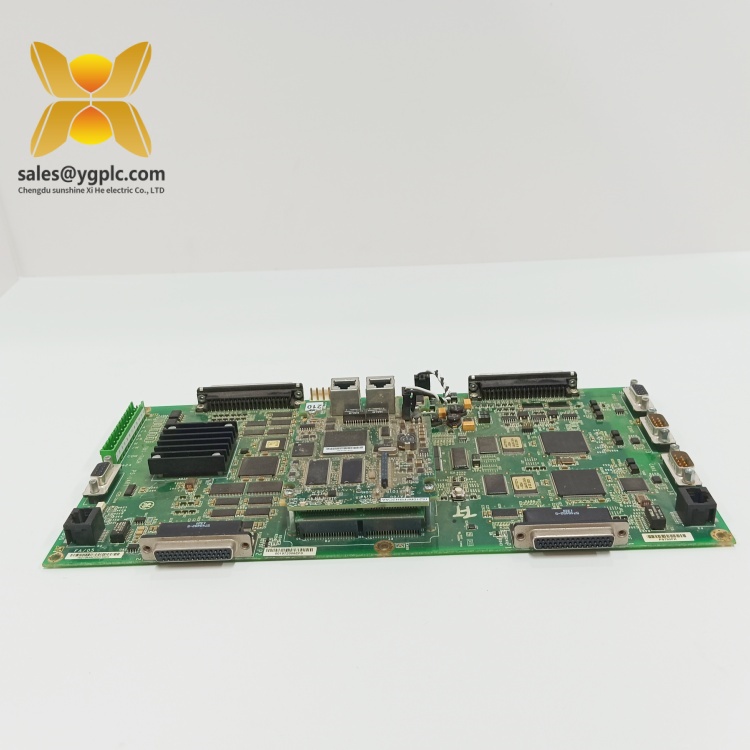

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS210MACCH2AEG |

| Manufacturer | General Electric (GE) |

| Product Type | Motor Control and Communication Module |

| Communication Ports | 1 × 10/100BaseT Ethernet, 1 × RS-485 |

| Supported Protocols | Modbus RTU, TCP/IP, UDP |

| Input Voltage | 24 VDC ±10% |

| Processor | 32-bit RISC microprocessor |

| Memory | 16 MB flash, 8 MB SRAM |

| Physical Dimensions | 240 mm (W) × 180 mm (H) × 80 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 9001 |

Main Features and Advantages

Application Areas

-

Power Generation:

- Controls steam turbine governors in thermal power plants, ensuring stable grid frequency and voltage.

- Manages gas turbine blade pitch in combined cycle power plants, optimizing energy efficiency and reducing emissions.

-

Oil and Gas:

- Regulates compressor motors in refineries and pipeline pumping stations, maintaining optimal flow rates.

- Integrates with emergency shutdown systems (ESD) in offshore platforms, ensuring safety during critical operations.

-

Manufacturing:

- Drives high-speed conveyor systems in automotive plants, enabling precise material handling.

- Controls robotic arm motors in pharmaceutical manufacturing, ensuring repeatable motion for quality control.

-

Water/Wastewater Treatment:

- Manages pump motors in water treatment facilities, maintaining consistent flow for filtration and chemical dosing.

- Integrates with SCADA systems for remote monitoring of distributed pumping stations.

Related Products

- GE IS210MACCZ1A: A legacy motor control module with similar functionality, often used as a predecessor to the GE IS210MACCH2AEG in older Mark VI systems.

- GE IS200MCCA: A communication adapter module that expands network connectivity for the GE IS210MACCH2AEG in large-scale setups.

- GE IS210PPROH1B: A power supply module that ensures stable 24 VDC for the GE IS210MACCH2AEG and other Mark VIe components.

- GE IS210TPROS1B: A temperature monitoring module that pairs with the GE IS210MACCH2AEG to provide comprehensive motor health analysis.

- GE IS210VCMCH1A: A voltage control module that works in tandem with the GE IS210MACCH2AEG for precise power regulation in generator applications.

Installation and Maintenance

Before installing the GE IS210MACCH2AEG, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control cabinet is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability.

- Use GE’s Proficy Machine Edition software to configure communication parameters (IP address, baud rate) and motor control settings based on application requirements.

- Mount the module in a 19″ rack with at least 30 mm of clearance for airflow, securing it with the provided brackets to minimize vibration.

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal, red for faults) and cleaning dust from ventilation slots with a soft brush.

- Firmware Updates: Periodically update the module’s firmware via GE’s software to access new features and security patches, especially when integrating with newer system versions.

- Functional Testing: Quarterly verification of motor control parameters using a calibrated load tester to ensure accuracy and responsiveness.

- Environmental Monitoring: Regularly assess ambient temperature and humidity levels to ensure they remain within the module’s operational range, particularly in harsh environments.

Product Warranty

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

GE IS200SRTDH2ACB | Mark VIe RTD Input Module | IS200STCIH2A

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200TBCIH1BBC | Contact Terminal Board, Mark VIe Series | IS200TDBSH2ACC

GE IS200TDBSH2ACC | Mark VIe Terminal Base Module |

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200TDBTH6ACD | Terminal Board Module | IS200TVIBH2BBB

GE IS200TPROH1BBB | Mark VIe Turbine Protection Module | IS200TBCIH2CAA

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: