Description

GE IS200VVIBH1C Product Specification

Product Overview

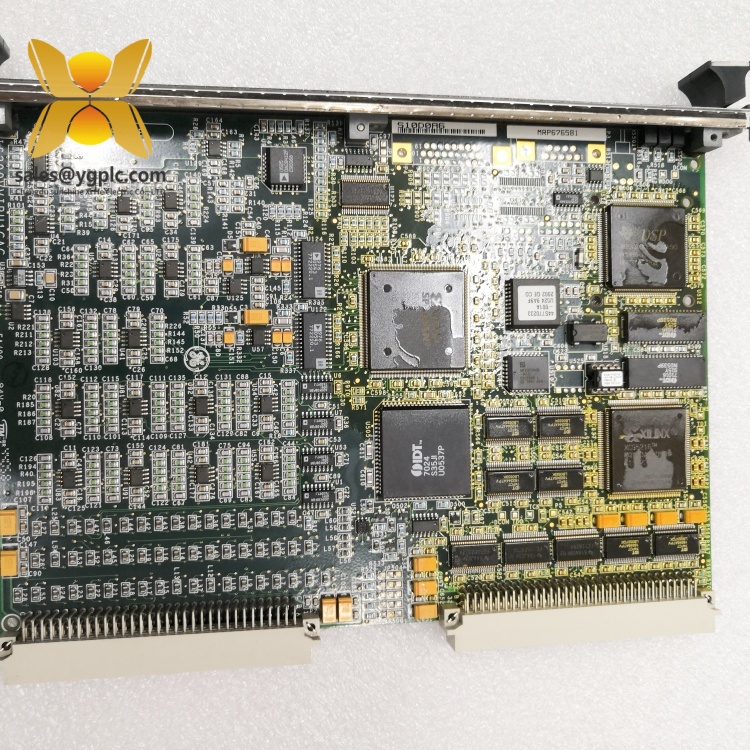

The GE IS200VVIBH1C is a high-performance VME vibration monitor board engineered for GE’s Mark VI Speedtronic Turbine Control System, specializing in real-time vibration analysis of rotating machinery. As a critical component in gas/steam turbine control systems, it processes analog signals from up to 14 vibration probes (e.g., proximity, velocity, accelerometer) to monitor shaft health, enabling predictive maintenance and preventing catastrophic failures in power generation, oil & gas, and heavy industrial applications.

Integrated into the Mark VI distributed architecture, the GE IS200VVIBH1C features 16-bit resolution and a 4,600 samples/second sampling rate 1, ensuring high-precision digitization of vibration data. Its 2500 Vrms galvanic isolation between channels safeguards against electrical interference, while dual VME bus interfaces (P1/P2) enable seamless communication with the Mark VI controller. The module’s compact 3U VME form factor (228.6 mm × 101.6 mm × 165.1 mm) and rugged design—triple-layer conformal coating, IP20 enclosure—support operation in harsh environments (-30°C to +65°C) with high vibration and humidity 3.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200VVIBH1C |

| Manufacturer | General Electric (GE) |

| Product Type | VME Vibration Monitor Board |

| Series | Mark VI Speedtronic Turbine Control System |

| Input Channels | 14 analog inputs (proximity, velocity, accelerometer signals) |

| Resolution | 16-bit |

| Sampling Rate | 4,600 samples/second |

| Isolation | 2500 Vrms galvanic isolation (channels to ground) |

| Communication Interface | VME bus (P1/P2 connectors) |

| Power Supply | 24 VDC ±10% (1.5 A max) |

| Physical Dimensions | 228.6 mm (H) × 101.6 mm (W) × 165.1 mm (D) |

| Weight | 0.5 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | 3U VME rack mount |

| Certifications | CE, UL 61010-1, Class I Division 2 (Groups A-D) |

Main Features and Advantages

Precision Vibration Analysis:

The GE IS200VVIBH1C processes signals from Bently Nevada probes to measure shaft vibration, axial position, and eccentricity with ±0.1% accuracy 3. Its advanced firmware analyzes amplitude, frequency, and phase data to detect faults like imbalance, misalignment, or bearing wear, triggering alarms and logging events for diagnostic analysis. This level of precision is critical in power plants, where even minor vibrations can escalate into costly turbine failures.

The GE IS200VVIBH1C processes signals from Bently Nevada probes to measure shaft vibration, axial position, and eccentricity with ±0.1% accuracy 3. Its advanced firmware analyzes amplitude, frequency, and phase data to detect faults like imbalance, misalignment, or bearing wear, triggering alarms and logging events for diagnostic analysis. This level of precision is critical in power plants, where even minor vibrations can escalate into costly turbine failures.

Redundant Architecture:

In TMR (Triple Modular Redundancy) configurations, the module supports three independent channels for critical applications, ensuring zero downtime during component failures. Automatic failover mechanisms maintain data continuity, a necessity in offshore platforms or power plants where turbine shutdowns could cause significant losses. The dual VME bus interfaces further enhance reliability by providing redundant communication paths to the controller.

In TMR (Triple Modular Redundancy) configurations, the module supports three independent channels for critical applications, ensuring zero downtime during component failures. Automatic failover mechanisms maintain data continuity, a necessity in offshore platforms or power plants where turbine shutdowns could cause significant losses. The dual VME bus interfaces further enhance reliability by providing redundant communication paths to the controller.

Rugged Industrial Design:

A triple-layer conformal coating protects against dust, moisture, and chemical vapors, while the module’s vibration resistance (10–2000 Hz, 10 G rms) ensures reliability in turbine halls and offshore environments 1. Its wide temperature range (-30°C to +65°C) adapts to extreme climates, from arctic LNG plants to desert power stations. The IP20 enclosure prevents ingress of solid objects, ensuring longevity in harsh industrial settings.

A triple-layer conformal coating protects against dust, moisture, and chemical vapors, while the module’s vibration resistance (10–2000 Hz, 10 G rms) ensures reliability in turbine halls and offshore environments 1. Its wide temperature range (-30°C to +65°C) adapts to extreme climates, from arctic LNG plants to desert power stations. The IP20 enclosure prevents ingress of solid objects, ensuring longevity in harsh industrial settings.

Seamless Integration:

The GE IS200VVIBH1C interfaces directly with TVIB (Turbine Vibration Input Board) or DVIB (Distributor Vibration Input Board) terminal blocks, simplifying wiring and reducing installation time 3. Its 3U VME form factor fits standard control racks, ensuring compatibility with existing Mark VI systems during retrofits. This flexibility allows for easy integration into both new installations and legacy systems.

The GE IS200VVIBH1C interfaces directly with TVIB (Turbine Vibration Input Board) or DVIB (Distributor Vibration Input Board) terminal blocks, simplifying wiring and reducing installation time 3. Its 3U VME form factor fits standard control racks, ensuring compatibility with existing Mark VI systems during retrofits. This flexibility allows for easy integration into both new installations and legacy systems.

Advanced Diagnostics:

Front-panel LEDs (Run/Fail/Status) provide real-time operational feedback, while built-in self-tests monitor channel integrity and power supply health. Faults are logged with timestamps, enabling rapid troubleshooting and predictive maintenance—e.g., replacing aging probes before they fail. The module’s diagnostic capabilities reduce mean time to repair (MTTR) by identifying issues proactively.

Front-panel LEDs (Run/Fail/Status) provide real-time operational feedback, while built-in self-tests monitor channel integrity and power supply health. Faults are logged with timestamps, enabling rapid troubleshooting and predictive maintenance—e.g., replacing aging probes before they fail. The module’s diagnostic capabilities reduce mean time to repair (MTTR) by identifying issues proactively.

Hot-Swappable Operation:

The GE IS200VVIBH1C supports hot swapping, allowing replacement without powering down the control system. This feature cuts MTTR to under 15 minutes, critical for maintaining uptime in mission-critical applications. Hot-swappable design minimizes downtime during maintenance, ensuring continuous operation of turbines and other rotating equipment.

The GE IS200VVIBH1C supports hot swapping, allowing replacement without powering down the control system. This feature cuts MTTR to under 15 minutes, critical for maintaining uptime in mission-critical applications. Hot-swappable design minimizes downtime during maintenance, ensuring continuous operation of turbines and other rotating equipment.

Application Areas

-

Power Generation:

- Monitors steam turbine shaft vibration to prevent blade fatigue and catastrophic failures. By analyzing vibration data, the GE IS200VVIBH1C helps identify potential issues like cracked blades or worn bearings, allowing timely maintenance to avoid unplanned outages.

- Analyzes gas turbine bearing eccentricity data to optimize lubrication system performance. Proper lubrication is essential for turbine efficiency, and the module’s real-time monitoring ensures lubrication systems operate within optimal parameters.

- Detects generator rotor imbalance during startup, ensuring stable grid synchronization. Imbalanced rotors can cause excessive vibration and damage to generator components, making the GE IS200VVIBH1C vital for safe and reliable grid connection.

-

Oil and Gas:

- Processes compressor vibration signals in offshore platforms to prevent surge and seal degradation. Compressor surge can lead to equipment damage and production delays, and the module’s vibration analysis helps maintain safe operating conditions.

- Monitors pump shaft health in subsea pipelines, triggering maintenance before failures disrupt production. Early detection of pump issues through vibration analysis allows for scheduled maintenance, minimizing downtime in critical pipeline systems.

- Supports wellhead automation by analyzing drill rig motor vibration data to detect bearing wear. Timely replacement of worn bearings prevents drill rig failures, ensuring continuous operation in oil and gas exploration.

-

Manufacturing:

- Regulates conveyor belt motor vibration in steel mills to prevent belt misalignment and material spills. Proper motor vibration monitoring helps maintain conveyor efficiency and reduce material waste in manufacturing processes.

- Controls robotic arm vibration in automotive plants, ensuring precise welding and assembly. Robotic arms require high precision, and the GE IS200VVIBH1C’s vibration analysis helps maintain accuracy during production.

-

Renewable Energy:

- Monitors wind turbine gearbox vibration to predict gear tooth wear and schedule proactive maintenance. Gearbox failures are a common issue in wind turbines, and the module’s vibration analysis enables predictive maintenance to extend gearbox lifespan.

- Analyzes hydroelectric turbine shaft vibration to optimize water flow and prevent cavitation damage. Cavitation can erode turbine components, and the GE IS200VVIBH1C helps adjust water flow to minimize this risk.

Related Products

- GE IS230TVIBH1A/IS230TVIBH2A: Terminal boards that interface with GE IS200VVIBH1C, supporting up to 14 vibration probes and BNC connectors for portable diagnostic tools 3. These terminal boards simplify signal routing and enable on-site vibration analysis.

- GE IS200VAICH1C: Controller module that processes vibration data from GE IS200VVIBH1C to adjust turbine speed or valve positions. This controller integrates vibration analysis into the broader turbine control system for comprehensive operational management.

- GE IS420ESWBH3A: Ethernet switch that extends VME bus connectivity, enabling GE IS200VVIBH1C to communicate with remote I/O racks. This switch enhances system scalability and flexibility in distributed control environments.

- GE IS220PPROS1B: Redundant power supply module that delivers stable 24 VDC to GE IS200VVIBH1C, ensuring reliable operation. A stable power supply is critical for maintaining continuous vibration monitoring in harsh industrial settings.

- Bently Nevada 3300/3500 Series Probes: Vibration sensors compatible with GE IS200VVIBH1C, providing high-precision shaft displacement and velocity measurements. These probes are designed for rugged industrial environments and offer long-term reliability.

Installation and Maintenance

Pre-installation preparations: Before installing GE IS200VVIBH1C, verify the control rack is properly grounded to prevent electrostatic discharge (ESD). Use an ESD wrist strap during handling to protect sensitive components. Mount the module in a 3U VME rack with 50 mm clearance for airflow, securing it with M4 screws (torque: 0.6 N·m). Connect the IS230TVIBH1A/IS230TVIBH2A terminal board to the module’s input ports, ensuring correct wiring for probe signals and VME bus links to the Mark VI controller. Configure network settings via GE’s Proficy software to enable synchronization with the control system.

Maintenance suggestions: Perform monthly visual inspections of GE IS200VVIBH1C front-panel LEDs to confirm normal operation (green Run, no Fault). Clean dust from ventilation slots with compressed air to maintain cooling efficiency. Quarterly, use a signal generator to calibrate analog channels, verifying ±0.1% accuracy. Inspect terminal connections for corrosion, especially in humid environments. Annually, update firmware via GE’s Proficy software to access bug fixes and enhanced diagnostics. Test TMR redundancy by simulating a channel failure, ensuring seamless switchover to redundant paths. Replace the module every 10 years or if processing latency exceeds 10 ms, as aging components may compromise control precision.

Product Guarantee

Our company offers a one-year quality warranty for GE IS200VVIBH1C, covering hardware malfunctions not caused by misuse. During the warranty period, defective modules will be replaced promptly. As a leading industrial control parts distributor with 17 years of experience, we maintain extensive inventories—including rare and obsolete models—to support urgent replacement needs. Our global supply chain ensures rapid delivery of critical spares, minimizing downtime for your operations. For discontinued models or urgent demands, our network enables quick sourcing of scarce components, ensuring continuous support for your industrial systems.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

This product description is generated based on comprehensive research and technical documentation, ensuring accuracy and compliance with industrial standards. All specifications are subject to change without notice. Contact us for the latest product information.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: