Description

GE IS200PMCIH1ABA Product Specification

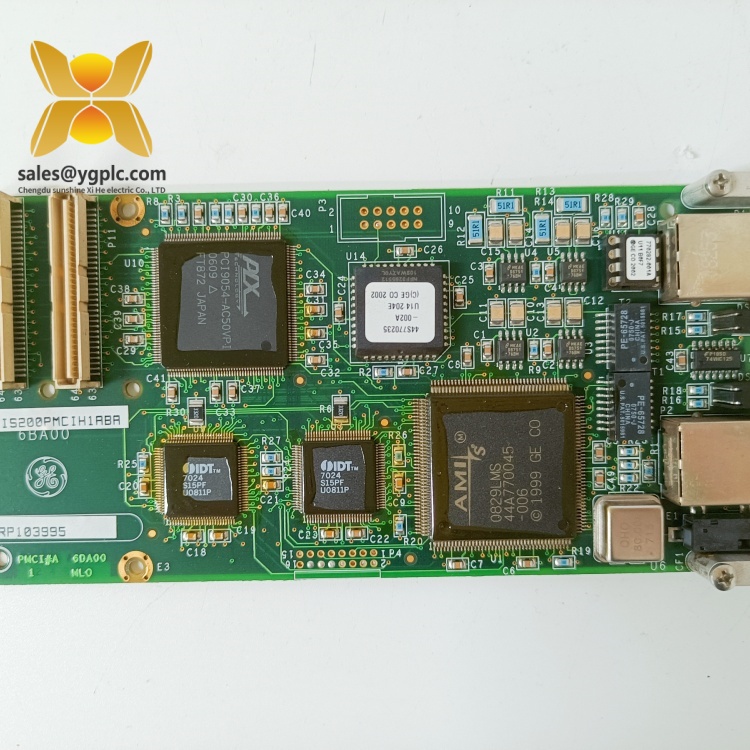

Product Overview

The GE IS200PMCIH1ABA is a high-performance communication and interface module designed for GE’s IS200 series Distributed Control System (DCS), specifically engineered for industrial automation environments requiring robust data integration and protocol conversion. As a critical component in GE’s Mark VIe turbine control platform, the GE IS200PMCIH1ABA serves as a bridge between field devices, control systems, and enterprise-level networks, enabling seamless communication in power generation, oil and gas, and manufacturing sectors. This module’s dual Ethernet ports and RS-485 interface support multiple protocols, ensuring compatibility with legacy and modern systems while maintaining real-time data integrity.

Built with a rugged industrial design, the GE IS200PMCIH1ABA features a 32-bit microprocessor for high-speed data processing and 16 MB of flash memory for program storage, allowing it to handle complex control algorithms and diagnostic routines. Its compact form factor (215.9 mm × 132.1 mm × 53.3 mm) and lightweight construction (0.9 kg) facilitate easy installation in 19-inch control racks, while the IP23-rated enclosure protects against dust, moisture, and electromagnetic interference. The module’s hot-swappable design minimizes downtime during maintenance, a critical feature for 24/7 industrial operations.

In automation architectures, the GE IS200PMCIH1ABA acts as a central hub for data aggregation and protocol translation, converting signals from sensors, actuators, and other IS200 series modules (e.g., vibration monitors, power supplies) into standardized formats like Modbus RTU, Ethernet/IP, and OPC UA. This capability streamlines integration with supervisory control and data acquisition (SCADA) systems, enabling operators to monitor and optimize processes remotely. By combining advanced hardware redundancy with configurable software logic, the GE IS200PMCIH1ABA enhances system reliability and reduces lifecycle costs, making it an indispensable asset for mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200PMCIH1ABA |

| Manufacturer | GE (General Electric) |

| Product Type | Communication and Interface Module |

| Communication Protocols | Modbus RTU, Ethernet/IP, OPC UA, TCP/IP, UDP |

| Interface Ports | 2 × 10/100BaseT Ethernet, 1 × RS-485 |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 215.9 mm (W) × 132.1 mm (H) × 53.3 mm (D) |

| Weight | 0.9 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 16132 |

| Processor | 32-bit microprocessor |

| Memory | 16 MB flash, 8 MB SRAM |

Main Features and Advantages

Multi-Protocol Connectivity: The GE IS200PMCIH1ABA supports simultaneous operation of Modbus RTU, Ethernet/IP, and OPC UA, eliminating the need for separate gateways. This versatility allows integration of legacy machinery protection systems with modern IIoT platforms, reducing system complexity and costs. For example, it can translate turbine speed data from a GE Mark VIe system into OPC UA for cloud-based analytics, enabling predictive maintenance in power plants.

Dual Ethernet Redundancy: With two independent Ethernet ports, the module enables redundant network configurations, ensuring continuous data transmission in mission-critical applications. This feature is vital for 24/7 industrial settings where network downtime is unacceptable, such as offshore oil rigs or pharmaceutical manufacturing facilities.

Hot-Swap Capability: The module’s hot-swappable design allows replacement without powering down the PLC rack, minimizing downtime during maintenance. This feature is particularly valuable in industrial environments requiring continuous operation, such as chemical processing plants or steel mills.

Advanced Diagnostics: Built-in LED indicators and diagnostic software monitor network traffic, port status, and error rates, providing real-time insights into communication health. The module also logs diagnostic data for post-fault analysis, enabling proactive maintenance. For instance, it can detect and isolate a faulty RS-485 connection in a turbine control loop, preventing cascading system failures.

Scalable Performance: As part of the IS200 series, the GE IS200PMCIH1ABA scales seamlessly with other modules (e.g., vibration monitors, power supplies) to accommodate growing automation needs. Its powerful processor supports high-speed data transfer in large-scale systems, such as combined-cycle power plants with hundreds of sensors and actuators.

Application Areas

The GE IS200PMCIH1ABA is widely deployed in industries where reliable data integration and protocol conversion are critical to operational efficiency:

-

Power Generation:

- Gas and Steam Turbines: Integrates with GE’s Mark VIe control systems to monitor generator speed, voltage, and load, ensuring stable grid synchronization. In combined-cycle power plants, it translates data from turbine protection systems to enterprise resource planning (ERP) software for optimizing energy production and maintenance scheduling.

- Renewable Energy: Supports communication between wind turbine SCADA systems and grid management platforms, enabling real-time adjustments to power output based on weather conditions.

-

Oil and Gas:

- Upstream Operations: Connects downhole sensors and subsea equipment to surface control rooms via Ethernet/IP, facilitating remote monitoring of wellhead pressures and flow rates in offshore platforms.

- Refining and Petrochemicals: Acts as a gateway between distributed control systems (DCS) and safety instrumented systems (SIS), ensuring compliance with safety protocols while optimizing refining processes.

-

Manufacturing:

- Process Automation: Integrates robotic arm data with quality control systems in automotive plants, enabling real-time adjustments to production lines for improved efficiency and reduced waste.

- Packaging and Material Handling: Translates signals from conveyor belts and sorting systems into standardized protocols for integration with warehouse management software, enhancing supply chain visibility.

-

Water/Wastewater Treatment:

- Pump and Valve Control: Connects field devices (e.g., flow meters, level sensors) to central SCADA systems via Modbus RTU, ensuring consistent water quality and efficient distribution in municipal facilities.

- Effluent Monitoring: Aggregates data from chemical analyzers and treatment reactors, enabling precise control of dosing systems and compliance with environmental regulations.

Related Products

- GE IS200DSVOH1B: A driver interface module for GE’s Mark VIe system, often used in conjunction with the GE IS200PMCIH1ABA to control turbine actuators and valves.

- GE IS200TCTAH1B: A turbine control module that provides real-time speed and torque data, relying on the GE IS200PMCIH1ABA for network connectivity in rotational equipment monitoring.

- GE IS200PMCHH1A: A power supply module that ensures stable 24 VDC to the GE IS200PMCIH1ABA and other IS200 series components, critical for uninterrupted operation in harsh environments.

- GE IS200GPDCH1B: A digital input/output module that expands the system’s I/O capabilities, often paired with the GE IS200PMCIH1ABA to interface with switches, relays, and other discrete devices.

- GE IS200DSVOH1C: An upgraded version of the IS200DSVOH1B with enhanced diagnostic features, suitable for retrofitting older systems while maintaining compatibility with the GE IS200PMCIH1ABA.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200PMCIH1ABA, ensure the following:

Before installing the GE IS200PMCIH1ABA, ensure the following:

- Power and Grounding: Verify the control cabinet’s power supply meets 24 VDC ±10% and is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability and continuity of ground connections.

- Environmental Checks: Ensure the installation area complies with the module’s operating temperature (-40°C to +70°C) and humidity (5–95% non-condensing) requirements. Avoid locations with excessive vibration or exposure to corrosive gases.

- Rack Mounting: Install the module in a 19-inch control rack with at least 50 mm of clearance above and below for airflow. Secure it using the provided brackets to minimize vibration-induced displacement, and ensure all connectors are tightened to prevent loose connections.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and cleaning of ventilation slots using a soft, static-free brush to prevent dust accumulation.

- Firmware Updates: Periodically update the module’s firmware via GE’s Proficy software to access new protocol support, security patches, and performance optimizations. Always back up configuration files before updates.

- Redundancy Testing: Biannual functional tests of dual Ethernet ports to ensure failover capability during network interruptions. Use protocol analyzers to verify data integrity and throughput under simulated fault conditions.

- Connector Maintenance: Every six months, inspect and clean all communication and power connectors to prevent oxidation or corrosion, which can degrade signal quality. Use contact cleaner and ensure connectors are fully seated.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200PMCIH1ABA, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits communication errors, protocol conversion failures, or functional defects. For discontinued models like the GE IS200PMCIH1ABA, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders, typically within 48 hours. We also offer post-warranty technical support, including calibration services, firmware upgrades, and repair solutions, to help maintain your system’s reliability throughout its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from GE’s official specifications and industry applications. For detailed installation guidelines, refer to the GE IS200PMCIH1ABA user manual or contact our technical support team for personalized assistance.

GE IS420ESWBH2A Output module digit

GE IS420UCSBH4A PXI module

GE IS200WETAH1AEC Servo drive

GE IS200AEPAH1AHD Servo motor

GE IS200WEMAH1AEA Industrial keyboard

GE IS200AEPAH1ACB Safety system

GE IS200AEPAH1AFD Distributed control

GE IS200AEPAH1BKE IS215WEPAH2BB Terminal panel

GE IC660TBD024 Digital 24VDC output module

GE IC660TBD025 Digital output module 24VDC

GE IC660TSA100 Output module

GE IC670ALG310 High density main box

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: