Description

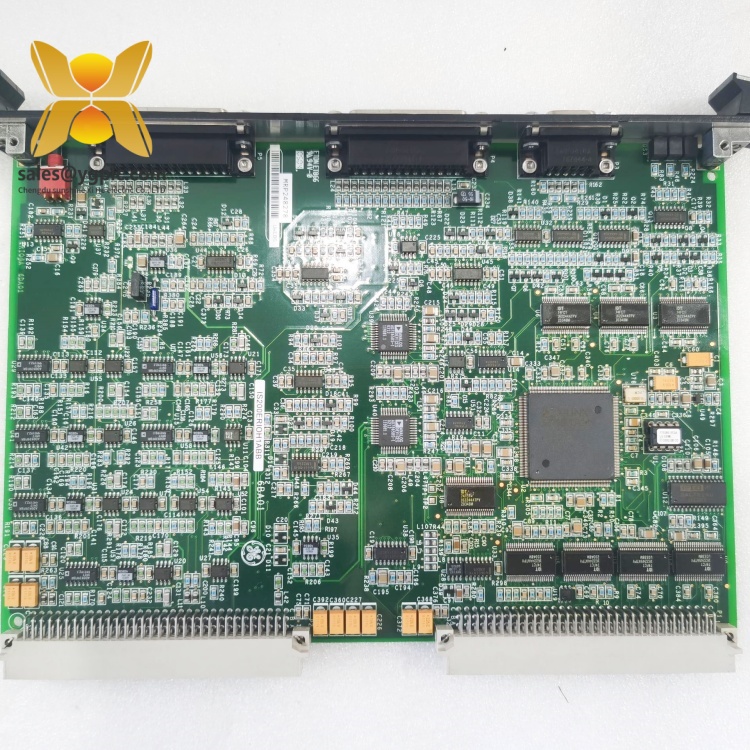

GE IS200ERIOH1ABB Mark VIe Remote I/O Module

Product Overview

The GE IS200ERIOH1ABB is a high-reliability Remote I/O Module designed as a critical component of GE’s Mark VIe distributed control system (DCS), catering to industrial automation and turbine control applications. Engineered to extend control system connectivity to remote field devices, this module enables seamless data exchange between the central controller and distributed I/O points, enhancing system flexibility and reducing cabling complexity in power generation, oil & gas, and manufacturing environments. As part of the IS200 Series, the IS200ERIOH1ABB integrates seamlessly with other Mark VIe components, such as control processors and communication gateways, forming a robust infrastructure for mission-critical operations.

Featuring a rugged industrial design, the GE IS200ERIOH1ABB supports high-speed data transmission over extended distances, with built-in error-checking and redundancy to ensure reliable performance. Its modular architecture allows configuration as either a master or slave in a remote I/O network, adapting to diverse system topologies. The module’s wide operating temperature range (-40°C to +85°C) and resistance to vibration and electromagnetic interference make it suitable for harsh industrial settings, while its hot-swappable design enables maintenance without system shutdowns. By bridging the gap between field instruments and the central control system, the IS200ERIOH1ABB enhances operational efficiency and reduces downtime in critical processes.

In automation ecosystems, the IS200ERIOH1ABB serves as a key interface for distributing control signals and acquiring real-time data from remote sensors and actuators. Its compatibility with GE’s proprietary protocols and industry-standard interfaces (e.g., Ethernet, Profibus) ensures seamless integration with both legacy and modern systems. By enabling remote I/O expansion, this module supports scalable control solutions, allowing industries to adapt to evolving operational needs without overhauling existing infrastructure.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200ERIOH1ABB |

| Manufacturer | GE |

| Product Type | Remote I/O Module |

| Platform | Mark VIe |

| Communication Protocol | Proprietary Mark VIe bus, compatible with Modbus, Ethernet/IP (via gateway) |

| Input Voltage | 24 V DC ±10% |

| Data Transfer Rate | Up to 100 Mbps |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Redundancy Support | Dual-channel redundant configuration |

| Certifications | CE, UL, IEEE 1131-2 |

Key Features and Advantages

Extended Remote Connectivity: The IS200ERIOH1ABB enables remote I/O expansion up to 100 meters from the central controller, reducing cabling costs and simplifying system layout in large industrial facilities. Its high-speed data transfer ensures minimal latency, critical for real-time control applications.

Redundant Architecture: Dual-channel redundancy ensures continuous operation even if one communication path fails, eliminating single points of failure. This feature is essential for maintaining system availability in 24/7 operations.

Rugged Industrial Design: Built with a metal enclosure and conformal-coated circuitry, the module withstands extreme temperatures, vibration, and humidity, meeting rigorous industrial standards (e.g., IEC 60068-2-6). This durability minimizes maintenance and replacement costs.

Hot-Swap Capability: The module can be replaced without powering down the system, allowing maintenance during operation. This reduces downtime and enhances productivity in time-sensitive industries.

Scalable System Integration: As part of the Mark VIe ecosystem, the IS200ERIOH1ABB supports seamless integration with GE’s Proficy software for configuration and monitoring, enabling scalable solutions from small setups to large-scale industrial networks.

Flexible Network Topology: Configurable as a master or slave, the module adapts to star, daisy-chain, or ring network topologies, providing flexibility to match diverse industrial requirements.

Application Areas

The GE IS200ERIOH1ABB is widely deployed in industries requiring remote I/O expansion and reliable data transmission:

- Power Generation: Extends I/O connectivity to remote sensors in steam turbines, generators, and auxiliary systems, enabling real-time monitoring of temperature, pressure, and flow rates in power plants.

- Oil & Gas: Connects with field instruments in refineries, pipeline compression stations, and offshore platforms, supporting remote control of valves, pumps, and safety systems.

- Manufacturing: Used in automotive, chemical, and food processing plants to link remote machinery (e.g., robotic arms, conveyors) with the central control system, ensuring precise process coordination.

- Water/Wastewater Treatment: Controls pumps and valves in treatment facilities, adapting to fluctuating flow demands while maintaining regulatory compliance.

Specific applications include:

- Turbine Remote Monitoring: Connects with vibration sensors and speed probes located far from the control room, enabling detailed analysis of turbine health without extensive cabling.

- Offshore Platform Automation: Extends control to remote wellheads and processing equipment, reducing infrastructure costs in offshore oil and gas operations.

- Large-Scale Manufacturing Lines: Coordinates distributed production cells in automotive plants, ensuring synchronized operation of remote machinery.

Related Products

- IS200ECHBH1AA (Communication Module): Enables Ethernet connectivity for the IS200ERIOH1ABB, supporting remote access and data logging.

- IS200ESWAH1AA (Switch Module): Forms part of the redundant network infrastructure, complementing the IS200ERIOH1ABB in large-scale I/O deployments.

- IS200EPWRH1AA (Power Supply Module): Provides redundant power to the remote I/O network, ensuring uninterrupted operation of the IS200ERIOH1ABB.

- IS200DSVOH1AA (Digital Output Module): Works with the IS200ERIOH1ABB to control remote actuators, forming a complete I/O solution.

- IS200AIHSH1AA (Analog Input Module): Acquires sensor data for transmission via the IS200ERIOH1ABB, supporting mixed-signal industrial applications.

- IS200TCTGG1A (Turbine Control Module): Coordinates with the IS200ERIOH1ABB to process remote I/O data for turbine speed and load control.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS200ERIOH1ABB, ensure the Mark VIe rack is properly grounded and ventilated. Verify the communication cable type (e.g., shielded twisted pair) and route it separately from high-voltage lines to minimize interference. Configure the module address using GE’s Proficy software, ensuring no address conflicts in the network. Mount the module in the rack using provided hardware, securing it with captive screws, and connect power and communication cables according to the wiring diagram.

Before installing the GE IS200ERIOH1ABB, ensure the Mark VIe rack is properly grounded and ventilated. Verify the communication cable type (e.g., shielded twisted pair) and route it separately from high-voltage lines to minimize interference. Configure the module address using GE’s Proficy software, ensuring no address conflicts in the network. Mount the module in the rack using provided hardware, securing it with captive screws, and connect power and communication cables according to the wiring diagram.

Maintenance Suggestions:

- Routine Checks: Monthly visual inspections for loose connections or overheating signs. Use Proficy software to monitor network health, ensuring stable data transmission and module status.

- Cleaning: Quarterly cleaning of the module’s vents with compressed air to prevent dust accumulation, especially in dusty environments.

- Redundancy Testing: Annually simulate network failures to verify redundant path activation, ensuring failover functionality. Document test results for compliance.

- Firmware Updates: Periodically update firmware via the Mark VIe controller to incorporate bug fixes and new features, following GE’s validated procedures.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS200ERIOH1ABB, covering hardware defects under normal use. In the event of operational issues, we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the IS200ERIOH1ABB and related spares. Our technical support team assists with installation, configuration, and troubleshooting, delivering reliable solutions to maintain your control system’s integrity.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IC697CPX928 Program module

GE IC697CPX928-CD Ethernet

GE IC697CPX928-FE Integrated protection device

GE IC697CPX935 Connecting module

GE IC697MDL652 driver

GE IC697MDL653 servo

GE IC660TBA026 Digital input module

GE IC660TBD024 Digital 24VDC output module

GE IC660TBD025 Digital output module 24VDC

GE IC660TSA100 Output module

GE IC670ALG310 High density main box

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: