Description

GE IS200ECTBG1ADE Product Specification

Product Overview

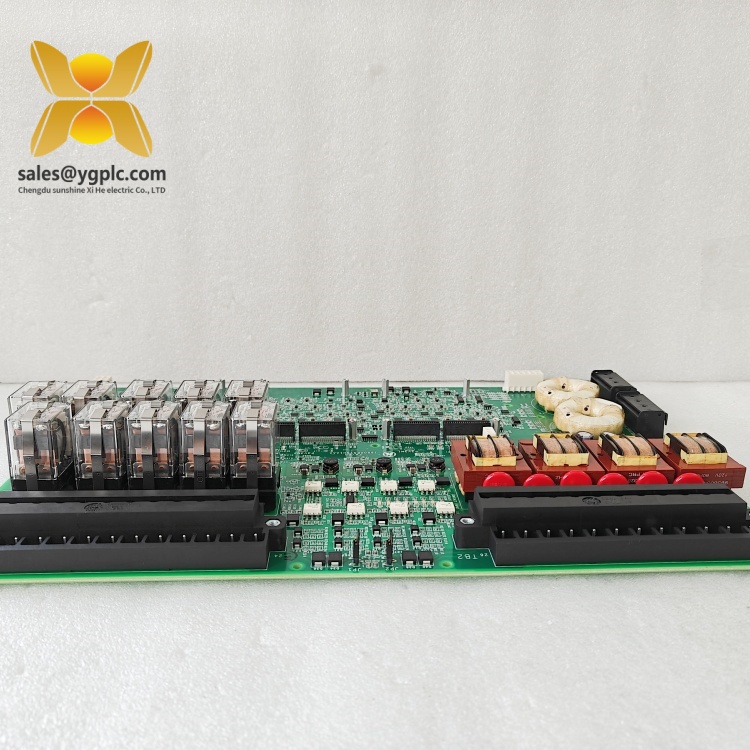

The GE IS200ECTBG1ADE is a high-reliability Exciter Contact Terminal Board engineered for GE’s Mark VI Turbine Control System, a cornerstone of industrial automation in power generation, oil and gas, and heavy machinery sectors. Designed to manage critical exciter contact functions in redundant control architectures, this module serves as a vital interface between turbine speed control systems and auxiliary equipment, ensuring seamless coordination of power generation processes. As part of the Mark VI series, the GE IS200ECTBG1ADE leverages GE’s decades of expertise in rotating equipment control, delivering precision, durability, and compatibility with legacy and modern automation platforms.

Constructed with dual power inputs (M1/M2) and six auxiliary contact terminals, the GE IS200ECTBG1ADE provides fail-safe operation in demanding environments. Its four form-C relay outputs, controlled by the adjacent EMIO board, enable precise switching of external devices such as circuit breakers, solenoids, or alarms. The module’s rugged design includes a thick conformal coating on critical components, protecting against dust, moisture, and electromagnetic interference (EMI), while its compact form factor (200 mm × 150 mm × 50 mm) and lightweight (1.2 kg) facilitate easy integration into 19″ control racks.

In automation systems, the GE IS200ECTBG1ADE acts as a frontline component in turbine protection schemes, ensuring rapid response to speed fluctuations or operational anomalies. Its backward compatibility with the first two revisions of the Mark VI series allows seamless upgrades in existing installations, reducing downtime and retrofit costs. By combining advanced relay technology with robust hardware, the module enhances system reliability, minimizes maintenance interventions, and supports continuous operation in mission-critical applications like steam turbine generators and gas compressor trains.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200ECTBG1ADE |

| Manufacturer | General Electric |

| Product Type | Exciter Contact Terminal Board |

| Series | Mark VI Speedtronic |

| Input Power | 24 VDC (M1/M2 dual redundant supplies) |

| Relay Outputs | 4 × Form-C relays (controllable via EMIO board) |

| Auxiliary Contacts | 6 inputs (for external device monitoring) |

| Communication Interface | Dependent on adjacent EMIO board (e.g., RS-485, Ethernet/IP via IS200EMIOH1A) |

| Physical Dimensions | 200 mm (W) × 150 mm (H) × 50 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Coating | Thick chemical protection on critical components |

| Certifications | CE, UL |

Main Features and Advantages

Redundant Power and Signal Paths: The GE IS200ECTBG1ADE features dual power inputs (M1/M2) and independent relay outputs, ensuring continuous operation even if one power source fails. This redundancy is critical in applications where downtime translates to significant operational losses, such as in power plant turbine control systems.

Flexible Relay Configuration: With four form-C relays and six auxiliary contacts, the module supports diverse switching requirements, from controlling generator field breakers to interfacing with external safety systems. The relays are rated for high switching currents (up to 5 A), making them suitable for both low-voltage logic signals and medium-power loads.

Rugged Industrial Design: The conformal coating on key components protects against harsh environmental factors, including oil mist, salt spray, and extreme temperature fluctuations. This durability ensures a long service life in offshore platforms, refineries, and other industrial settings with aggressive operating conditions.

Backward Compatibility: Designed to work with the first two revisions of the Mark VI series, the GE IS200ECTBG1ADE allows easy retrofitting into legacy systems without hardware modifications. This feature minimizes upgrade costs and simplifies inventory management for plants using mixed generations of GE control equipment.

Efficient Heat Dissipation: The module’s compact yet ventilated design ensures optimal heat dissipation, preventing thermal stress-induced failures during prolonged high-load operation. This thermal stability is essential for maintaining signal integrity in high-temperature environments like gas turbine enclosures.

Application Areas

The GE IS200ECTBG1ADE is widely deployed in industries requiring precise control and monitoring of rotating machinery:

-

Power Generation:

- In thermal power plants, it manages exciter contacts in steam turbines, ensuring stable voltage regulation and synchronization with the grid.

- Integrates with gas turbine control systems to monitor speed and trigger protective shutdowns in case of overspeed or mechanical anomalies.

-

Oil and Gas:

- Controls compressor trains in refineries and pipeline stations, enabling safe start-stop sequences and load sharing between units.

- Monitors torque and vibration sensors in pump systems, interfacing with emergency shutdown (ESD) protocols to prevent catastrophic failures.

-

Heavy Industry:

- Supports metallurgical processes by managing motor drives in rolling mills and blast furnaces, ensuring consistent rotational speed for quality control.

- Used in cement plants to coordinate kiln drives and conveyor systems, reducing downtime through reliable relay switching.

-

Marine Propulsion:

- Installed in ship engines to regulate generator speed and power distribution, ensuring uninterrupted operation during transoceanic voyages.

- Works with diesel-electric propulsion systems to interface between the engine control unit (ECU) and auxiliary machinery.

Related Products

- GE IS200ECTBG1A: The base model of the Exciter Contact Terminal Board series, featuring fewer revisions and single-power input design, often used in simplex systems.

- GE IS200EMIOH1A: An adjacent EMIO (External Mount I/O) board that controls the relays of the GE IS200ECTBG1ADE, enabling communication with higher-level control systems.

- GE IS200PWRBH1B: A redundant power supply module for the Mark VI system, ensuring stable 24 VDC to the GE IS200ECTBG1ADE and other rack-mounted components.

- GE IS200DSCCG1A: A digital speed control card that pairs with the GE IS200ECTBG1ADE to provide precise speed regulation in turbine applications.

- GE IS200TURBG1A: A turbine control module that integrates with the GE IS200ECTBG1ADE to manage fuel valves and ignition sequences in gas turbines.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200ECTBG1ADE, ensure the following:

Before installing the GE IS200ECTBG1ADE, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to check voltage stability and continuity.

- Clean the mounting area to remove dust and debris, and ensure the rack has sufficient space (at least 50 mm clearance) for airflow around the module.

- Use anti-static gloves and packaging during handling to protect sensitive circuitry. Secure the module in the rack using the provided DIN rail or screw mounts, tightening fasteners to 0.5–1.0 Nm torque to avoid damage.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and relay contacts for signs of arcing or wear. Clean the module’s ventilation slots with a soft brush to maintain airflow efficiency.

- Functional Testing: Quarterly verification of relay operation using a test light or multimeter to confirm proper switching. Simulate fault conditions (e.g., loss of M1 power) to ensure redundancy mechanisms activate correctly.

- Coating Integrity: Annually inspect the conformal coating for cracks or delamination, especially in high-humidity environments. Repair or reapply coating as needed to maintain EMI and corrosion protection.

- Firmware Updates: Periodically update the firmware of adjacent EMIO boards (if applicable) to ensure compatibility with the GE IS200ECTBG1ADE, particularly when integrating with newer Mark VI system revisions.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200ECTBG1ADE, covering hardware malfunctions due to defects in materials or workmanship. During the warranty period, we will replace any module that exhibits relay contact failures, power supply instability, or coating degradation not caused by misuse or environmental extremes. For discontinued models like the GE IS200ECTBG1ADE, our global inventory of legacy GE parts ensures rapid fulfillment of urgent orders, minimizing downtime for critical systems. We also offer post-warranty technical support, including calibration services and component-level repairs, to help maintain your equipment’s reliability throughout its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

GE IC697MDL671 Expansion rack

GE IC697MDL740 Network communication module

GE IC697MDL750 DCS spare parts

GE IC697MEM717C PLC central processing unit

GE IC670ALG310 Power strip

GE IS200TRPGH1BDD S1C5029 Servo drive

GE IS200AEPAH1ACB Safety system

GE IS200AEPAH1AFD Distributed control

GE IS200AEPAH1BKE IS215WEPAH2BB Terminal panel

GE IC670CPU350 Communication input interface component

GE IC660BBD023 Connection base plate

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: