Description

GE IS200AEPCH1BAA Product Specification

Product Overview

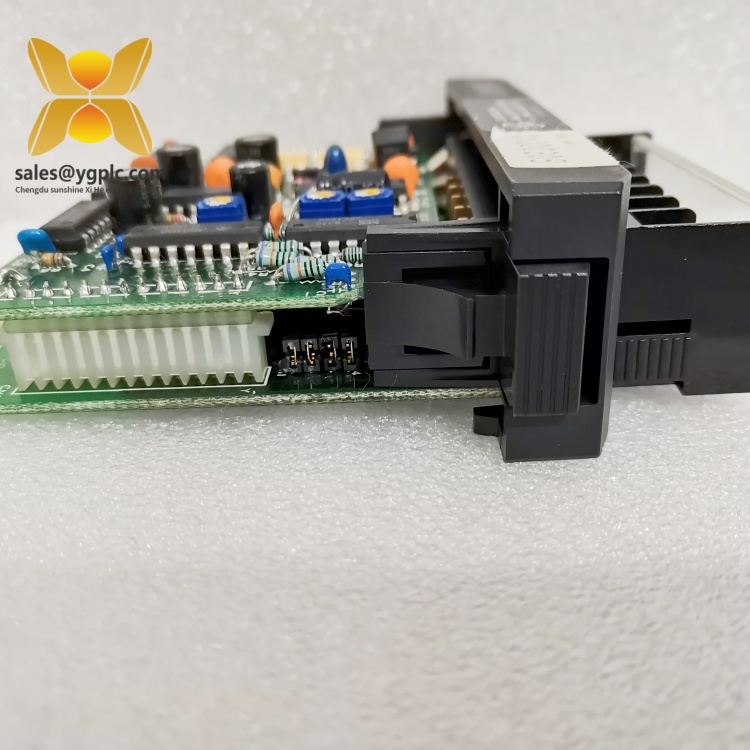

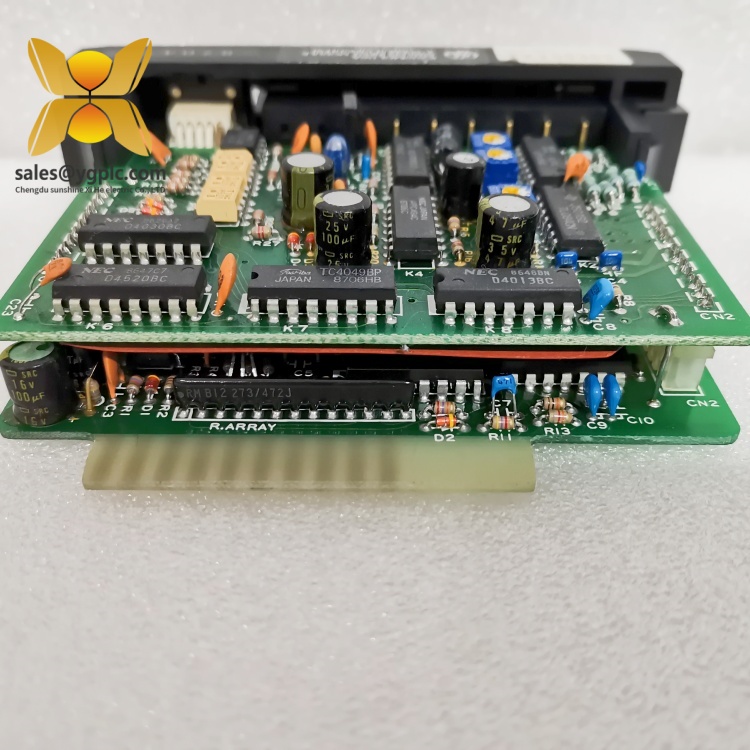

The GE IS200AEPCH1BAA is a high-reliability analog input/output (I/O) module designed for GE’s Mark VIe Turbine Control Platform, catering to mission-critical industrial automation systems. Engineered to handle precise signal conditioning and real-time data acquisition, the GE IS200AEPCH1BAA serves as a vital component in turbine control systems, enabling seamless integration of analog sensors and actuators in power generation, oil and gas, and heavy manufacturing sectors. As part of GE’s legacy IS200 series, this module combines robust hardware with flexible configuration, ensuring reliable operation in harsh industrial environments.

The GE IS200AEPCH1BAA features 16 channels of analog input (AI) and 8 channels of analog output (AO), supporting signal ranges such as 4–20 mA and 0–10 VDC. Its 16-bit resolution ensures high-precision measurement and control, while built-in surge protection safeguards against electrical disturbances. The module’s compact design (178 mm × 102 mm × 254 mm) and rugged metal enclosure allow for easy integration into rack-mounted systems, with a weight of 1.8 kg facilitating installation in space-constrained environments. Compatible with GE’s Proficy software suite, the GE IS200AEPCH1BAA enables engineers to configure channel parameters and perform diagnostics remotely, minimizing downtime and enhancing system efficiency.

In automation architectures, the GE IS200AEPCH1BAA acts as a bridge between field devices and the turbine control system, processing real-time data from temperature, pressure, and flow sensors while delivering control signals to actuators. Its dual-channel redundancy support ensures continuous operation even in the event of a channel failure, making it ideal for safety-critical applications. By combining high-speed signal processing with industry-standard connectivity, the module empowers industries to optimize turbine performance, reduce energy consumption, and maintain regulatory compliance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200AEPCH1BAA |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Input/Output Module |

| Channels | 16 AI, 8 AO |

| Signal Range | AI: 4–20 mA, 0–10 VDC; AO: 4–20 mA, 0–10 VDC |

| Resolution | 16-bit |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 178 mm (W) × 102 mm (H) × 254 mm (D) |

| Weight | 1.8 kg |

| Communication Protocol | Proprietary GE Mark VIe bus |

| Operating Temperature | -40°C to +70°C |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Certifications | CE, UL, ISO 10873 |

Main Features and Advantages

Dual-Mode Signal Handling: The GE IS200AEPCH1BAA supports both analog input and output channels, offering versatility for hybrid control systems. Its 16 AI channels with 16-bit resolution enable precise measurement of continuous variables (e.g., turbine speed, steam pressure), while 8 AO channels deliver stable control signals to valves and actuators, reducing the need for separate modules and simplifying system architecture.

Enhanced Redundancy Design: With support for dual-channel redundancy, the module ensures uninterrupted operation by automatically switching to a backup channel in case of failure. This feature is critical in mission-critical applications like power plant turbines, where downtime can lead to significant losses.

Robust Industrial Construction: Built with a reinforced metal casing and conformal-coated PCBs, the GE IS200AEPCH1BAA resists dust, moisture, and electromagnetic interference (EMI), making it suitable for harsh environments such as offshore oil platforms or steel mills. Its wide temperature range eliminates the need for additional climate control, lowering installation and maintenance costs.

Seamless Software Integration: Compatible with GE’s Proficy Machine Edition, the module allows users to configure channel parameters, apply signal filtering, and set alarm thresholds via a unified interface. This software-defined flexibility enables quick adaptation to changing process requirements without hardware modifications.

Proactive Diagnostics: Integrated self-test (BIST) functionality monitors channel health, power supply stability, and thermal conditions, providing real-time feedback via front-panel LEDs and the control system’s HMI. Diagnostic logs help identify potential issues before they escalate, reducing mean time to repair (MTTR).

Application Areas

The GE IS200AEPCH1BAA is widely deployed in industries requiring precise analog signal management and reliable turbine control:

-

Power Generation:

- Monitors steam turbine parameters (temperature, pressure, flow) in combined cycle power plants, enabling real-time adjustments to fuel supply and blade positioning for optimal efficiency.

- Supports generator excitation control by processing analog signals from voltage sensors and delivering control outputs to exciters, ensuring grid stability.

-

Oil and Gas:

- Manages pipeline pressure and flow rates by integrating with analog pressure transducers and control valves in upstream and downstream processes.

- Controls compressor anti-surge systems in refineries, using AI channels to measure differential pressure and AO channels to adjust valve positions.

-

Industrial Manufacturing:

- Regulates temperature and pressure in chemical reactors by processing analog inputs from RTDs and thermocouples, while AO channels control heating elements or cooling valves.

- Maintains precision in paper mill drying cylinders by adjusting steam flow based on analog moisture sensor inputs.

-

Marine Propulsion:

- Monitors engine performance parameters (e.g., exhaust temperature, lubricant pressure) in marine turbines, delivering control signals to fuel injectors for dynamic load balancing.

- Monitors engine performance parameters (e.g., exhaust temperature, lubricant pressure) in marine turbines, delivering control signals to fuel injectors for dynamic load balancing.

Related Products

- GE IS200WEMAH1AEA: A turbine control I/O module with similar form factor, supporting both analog and digital signals for hybrid control systems.

- GE IS200TCTAH1B: A turbine control module with advanced PID tuning, often paired with the GE IS200AEPCH1BAA for closed-loop speed control in turbines.

- GE IS200AEBIH1BED: A communication module with dual Gigabit Ethernet ports, enabling the GE IS200AEPCH1BAA to integrate with modern IIoT platforms for remote monitoring.

- GE IS200DSVIH1A: A servo drive interface module that converts digital control signals to analog outputs, complementing the GE IS200AEPCH1BAA in motion-intensive applications.

- GE IS200PTVIH1A: A pressure transducer interface module for high-accuracy pressure measurements, expanding the system’s sensor compatibility.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200AEPCH1BAA, ensure the following:

Before installing the GE IS200AEPCH1BAA, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control rack is properly grounded to prevent electrostatic discharge (ESD).

- Use GE’s TurboGear software to configure AI/AO channel types, input/output ranges, and alarm thresholds based on sensor and actuator specifications.

- Mount the module in a 19″ rack with at least 50 mm of clearance for airflow, avoiding proximity to high-heat components.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal, red for faults) and cleaning dust from ventilation slots to maintain optimal cooling.

- Calibration: Annual calibration of AI/AO channels using certified test equipment to ensure measurement accuracy within ±0.1% of full scale.

- Firmware Updates: Periodic updates via GE’s programming software to access bug fixes and compatibility improvements with newer control system versions.

- Redundancy Testing: Biannual verification of dual-channel redundancy functionality to ensure failover reliability in critical applications.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200AEPCH1BAA, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits signal processing anomalies or functional defects. For discontinued models like the GE IS200AEPCH1BAA, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services through certified technicians, ensuring your automation systems remain operational and reliable over the long term.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This description is based on GE’s official specifications and industry applications. For detailed installation guides, refer to the GE IS200AEPCH1BAA user manual or contact our technical support team.

GE IC660TBD024 Gas turbine card

GE IC670CHS101 FIM card

GE IC670CPU350 Communication input interface component

GE IC660BBD023 Connection base plate

GE IC660BBD025 redundancy

GE IC660BBD101 Network communication

GE IC660BBD110 Safety system

GE IC660EBD020 Distributed control

GE IS200JPDMG1ACC S1AT005 display

GE IS200TSVCH1AED Relay output

GE SR469 469-P5-HI-A20-E RXM rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: