Description

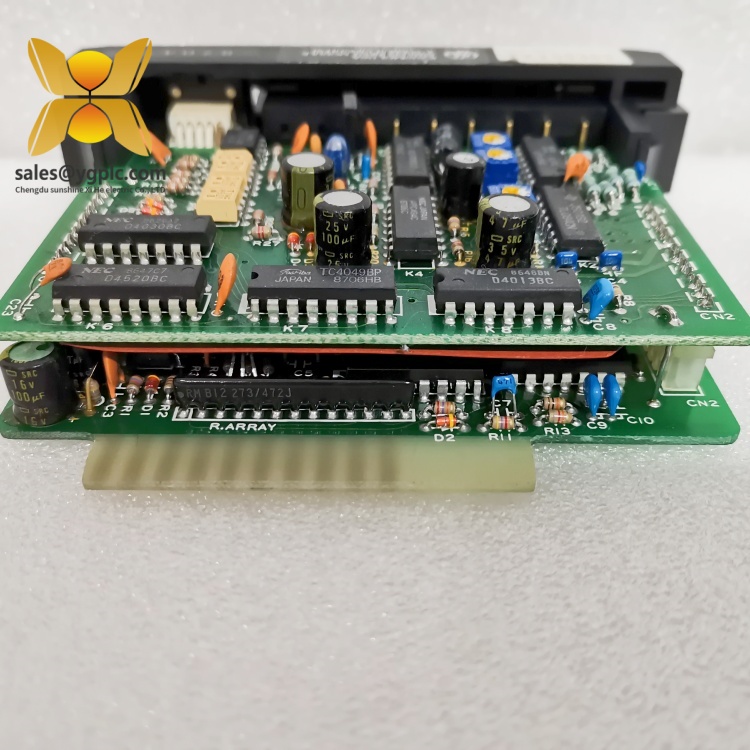

GE IP-QUADRATURE Encoder Interface Module

Product Overview: GE IP-QUADRATURE

The GE IP-QUADRATURE encoder interface module is a high-precision industrial component designed for precise position and speed measurement in GE’s automation systems. Engineered to interface with quadrature encoders, this module converts analog encoder signals into digital data for PLCs and DCS systems, enabling accurate motion control and feedback in manufacturing, robotics, and material handling applications. As a versatile solution for rotational and linear position tracking, the IP-QUADRATURE module supports multiple encoder types, including incremental and absolute encoders, making it an essential component for precision automation setups.

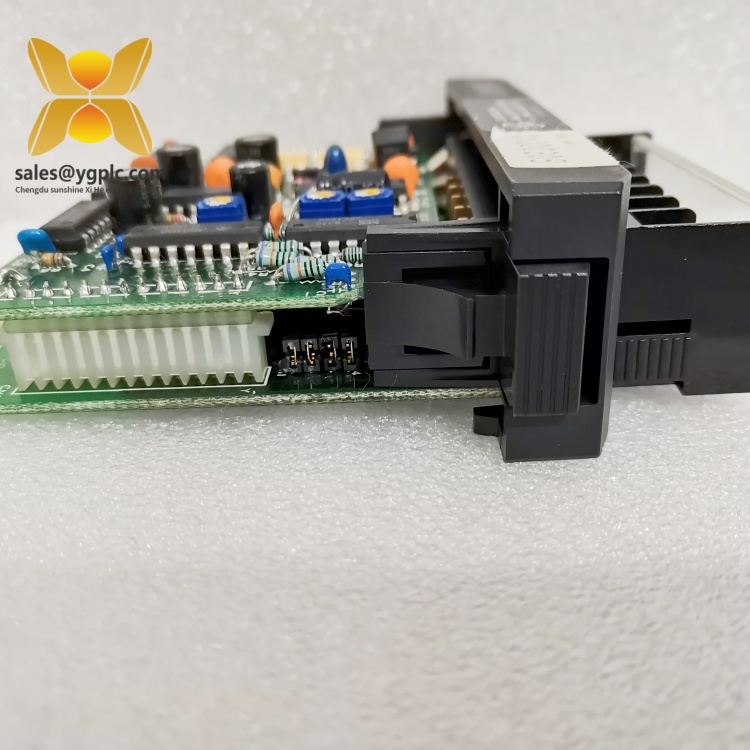

Featuring a robust design, the IP-QUADRATURE module integrates advanced signal conditioning and noise filtering to ensure reliable operation in harsh industrial environments. Its 5–24V DC input range and RS422 differential signal processing minimize interference, while built-in diagnostics monitor encoder health and signal integrity. The module’s compact form factor (110mm x 90mm x 60mm) and DIN rail mounting compatibility simplify integration into existing control cabinets, while its -40°C to +70°C operating range ensures durability in extreme conditions.

In automation architectures, the IP-QUADRATURE module serves as a critical link between mechanical systems and control processors, enabling real-time feedback for closed-loop control. Its ability to handle high-frequency encoder signals (up to 10 MHz) makes it suitable for high-speed applications, such as CNC machines, conveyor systems, and robotic arms. By translating encoder outputs into usable data for GE’s PLCs (e.g., 90-30 or 90-70 Series), the module enhances system accuracy and repeatability, reducing errors and improving production efficiency.

Technical Specifications: GE IP-QUADRATURE

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IP-QUADRATURE |

| Manufacturer | GE |

| Product Type | Encoder Interface Module |

| Input Voltage | 5–24V DC |

| Signal Type | Quadrature encoder (A/B/Z channels) |

| Max Input Frequency | 10 MHz |

| Communication Interface | RS422 (differential) |

| Output Format | Digital (TTL/CMOS compatible) |

| Physical Dimensions | 110 mm (H) × 90 mm (W) × 60 mm (D) |

| Weight | 0.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail |

| Country of Origin | United States |

Main Features and Advantages: GE IP-QUADRATURE

High-Precision Encoding: The IP-QUADRATURE module processes encoder signals with sub-millimeter accuracy, enabling precise position tracking in applications requiring tight tolerance, such as semiconductor manufacturing or medical device assembly. Its ability to count up/down pulses and detect direction ensures reliable motion feedback.

Robust Signal Conditioning: Equipped with noise-filtering circuitry, the module withstands electromagnetic interference (EMI) and voltage spikes, maintaining signal integrity in noisy environments like welding stations or heavy machinery areas. This reliability reduces system downtime caused by encoder errors.

Flexible Configuration: Users can configure the module for different encoder resolutions and signal polarities via dip switches or software, adapting to various encoder types without hardware changes. This flexibility supports quick system reconfiguration for different production needs.

Real-Time Diagnostics: Built-in LED indicators and fault reporting enable real-time monitoring of encoder health, signal loss, and power status. This proactive diagnostics feature allows operators to address issues before they escalate, minimizing maintenance costs.

Compact and Durable Design: The module’s rugged enclosure and wide temperature range make it suitable for harsh industrial settings, while its compact size optimizes space in crowded control panels. The DIN rail mounting further simplifies installation and replacement.

Application Areas: GE IP-QUADRATURE

The GE IP-QUADRATURE encoder interface module is ideal for industries demanding precise motion control:

- Manufacturing: Integrates with CNC machines, robotic arms, and assembly lines to monitor spindle position, conveyor speed, and robotic joint movement, ensuring production consistency and quality.

- Material Handling: Tracks the position of overhead cranes, forklifts, and automated guided vehicles (AGVs), enabling safe and efficient load placement in warehouses and logistics centers.

- Packaging: Controls the speed and position of labeling machines, filling systems, and conveyor belts in food & beverage or pharmaceutical packaging lines, maintaining regulatory compliance.

- Aerospace: Supports precision positioning in aircraft component manufacturing, such as wing assembly or engine part alignment, where millimeter-level accuracy is critical.

- Renewable Energy: Monitors the rotation of wind turbine blades and solar panel tracking systems, optimizing energy capture and reducing mechanical stress.

Related Products: GE IP-QUADRATURE

- GE IC693CMM301: A communication module compatible with the IP-QUADRATURE, enabling Ethernet/IP connectivity for remote encoder data monitoring.

- GE IC693MDL645: A digital input module that works alongside the IP-QUADRATURE to integrate encoder signals with GE’s 90-30 Series PLCs.

- GE IC697CPU780: A high-performance CPU module that processes encoder data from the IP-QUADRATURE for complex motion control algorithms.

- GE IC693ACC300: An accessory module that expands the I/O capabilities of GE’s PLC systems, supporting additional encoder interfaces.

- GE IC695CPE305: A compact PLC controller that pairs with the IP-QUADRATURE for small-scale motion control applications.

- GE IC697ALG724: An analog output module that converts encoder data from the IP-QUADRATURE into variable signals for drive control.

Installation and Maintenance: GE IP-QUADRATURE

Pre-installation Preparations:

Before installing the IP-QUADRATURE, verify the power supply (5–24V DC) and ensure the control cabinet is properly grounded to minimize EMI. Mount the module on a DIN rail, leaving 25mm clearance for ventilation. Connect the encoder cables to the terminal block, ensuring shielded wiring to reduce noise. Configure the module’s dip switches for encoder type and resolution, then link it to the PLC via RS422 cables, following GE’s wiring diagrams.

Before installing the IP-QUADRATURE, verify the power supply (5–24V DC) and ensure the control cabinet is properly grounded to minimize EMI. Mount the module on a DIN rail, leaving 25mm clearance for ventilation. Connect the encoder cables to the terminal block, ensuring shielded wiring to reduce noise. Configure the module’s dip switches for encoder type and resolution, then link it to the PLC via RS422 cables, following GE’s wiring diagrams.

Maintenance Recommendations:

- Routine Checks: Monthly inspections should include verifying LED status indicators, tightening cable connections, and cleaning the module’s surface to prevent dust accumulation.

- Signal Testing: Quarterly use a oscilloscope to monitor encoder signals for distortion or loss, replacing faulty cables or encoders promptly.

- Firmware Updates: Periodically check GE’s support portal for firmware updates to ensure optimal performance and compatibility with new encoder technologies.

- Environmental Monitoring: Maintain ambient temperature below 70°C and humidity below 95% to prevent component degradation, installing additional cooling if necessary.

Product Guarantee: GE IP-QUADRATURE

Our company provides a 12-month quality warranty for the GE IP-QUADRATURE encoder interface module, covering non-human-induced hardware defects. During the warranty period, we will replace any module with signal processing failures or physical damage at no cost. For discontinued models or urgent needs, our global supply chain network ensures rapid delivery of spare parts, minimizing downtime and supporting continuous operation.

With 17 years of expertise in industrial control distribution, we prioritize reliable solutions and exceptional service. The IP-QUADRATURE module exemplifies our commitment to precision and durability, enabling efficient motion control in critical applications. Contact us today to enhance your automation system’s accuracy with this robust encoder interface.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for GE’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IC698PSA100 redundancy

GE IC698PSA100D Network communication

GE IC754CSL12CTD Safety system

GE IC800SSI216RD2-CE Distributed control

GE IC800SSI228RD2-CE Terminal panel

GE IC800SSI228RD2-EE PDP panel

GE INTELLIX MO150 programmable

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: