Description

GE IC697CPU781 Product Specification

Product Overview

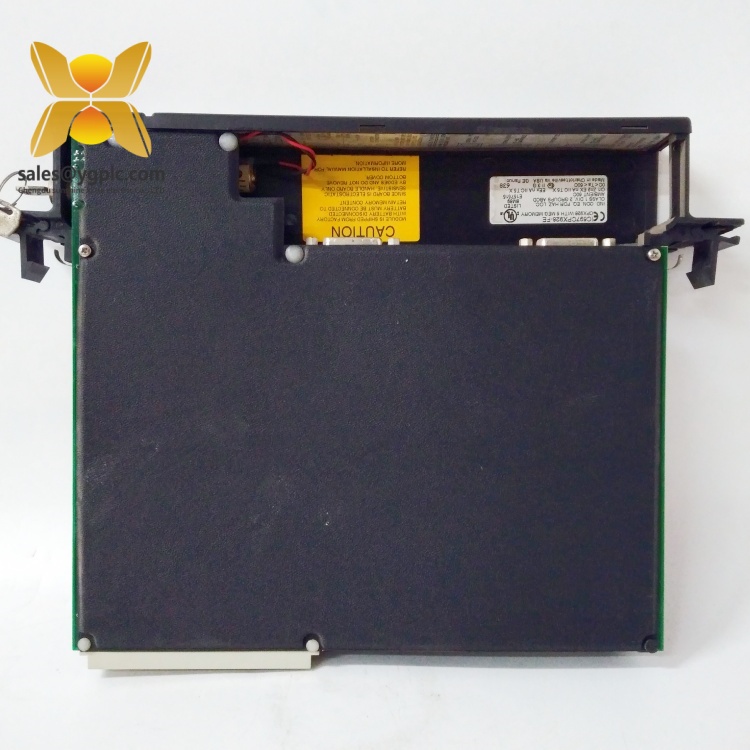

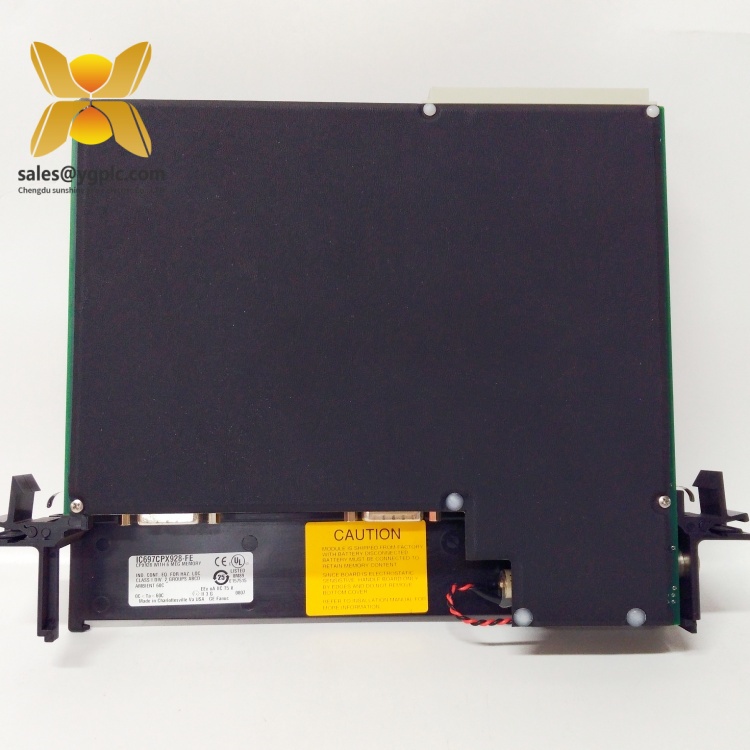

The GE IC697CPU781 is a high-performance CPU module engineered for GE’s Series 90-70 PLC platform, serving as the processing core for industrial automation systems in manufacturing, power generation, and process control. As the central command unit of the Series 90-70 architecture, this module executes complex control logic, manages I/O modules, and coordinates communication with external devices, ensuring precise and reliable operation in mission-critical applications.

Integrated into the Series 90-70 system, the GE IC697CPU781 features a 32-bit RISC processor with a clock speed of 100 MHz, delivering fast execution of ladder logic, structured text, and function block diagrams—up to 5,000 instructions per millisecond. Its robust design includes 512 KB of user memory and 2 MB of non-volatile flash memory for program storage, ensuring data retention during power outages. The module supports genius bus communication for seamless integration with Series 90-70 I/O modules, as well as RS-232 and RS-485 ports for connecting HMIs, printers, and other peripherals.

The GE IC697CPU781’s compact form factor (114 mm × 229 mm × 152 mm) and rugged construction—including a conformal coating and IP20-rated enclosure—enable reliable operation in temperatures ranging from 0°C to 60°C, with resistance to vibration (10–2000 Hz, 10 G rms) and humidity (5–95% non-condensing). Front-panel LEDs provide real-time status monitoring for power, run mode, and communication, simplifying troubleshooting. Compatibility with GE’s Proficy PLC Programming Software allows easy configuration of control logic, while its support for hot standby redundancy (when paired with a second GE IC697CPU781) ensures uninterrupted operation in systems where downtime is costly, such as chemical batch processing or turbine control.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC697CPU781 |

| Manufacturer | General Electric (GE) |

| Product Type | PLC CPU Module |

| Series | Series 90-70 PLC Platform |

| Processor | 32-bit RISC, 100 MHz |

| Memory | 512 KB user memory, 2 MB non-volatile flash memory |

| Communication Ports | 1 × RS-232, 1 × RS-485, 1 × Genius bus interface |

| Supported Protocols | Modbus RTU, Genius bus protocol, ASCII |

| Physical Dimensions | 114 mm (H) × 229 mm (W) × 152 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | 0°C to +60°C |

| Humidity | 5–95% non-condensing |

| Power Supply | 5 VDC (from backplane), 24 VDC (external for real-time clock) |

| Redundancy Support | Hot standby (requires second GE IC697CPU781 and IC697RNR701 redundancy module) |

| Mounting Type | Series 90-70 rack mount (compatible with IC697CHS791 10-slot rack) |

| Certifications | CE, UL 508, CSA C22.2 No. 142 |

Main Features and Advantages

High-Speed Processing:

The GE IC697CPU781’s 100 MHz 32-bit RISC processor executes control logic at up to 5,000 instructions per millisecond, enabling rapid response in time-sensitive applications. For example, in automotive assembly lines, it synchronizes robotic welding arms with conveyor belts, ensuring precise part alignment within 10 ms—critical for maintaining product quality and production throughput.

The GE IC697CPU781’s 100 MHz 32-bit RISC processor executes control logic at up to 5,000 instructions per millisecond, enabling rapid response in time-sensitive applications. For example, in automotive assembly lines, it synchronizes robotic welding arms with conveyor belts, ensuring precise part alignment within 10 ms—critical for maintaining product quality and production throughput.

Robust memory and data retention:

With 512 KB of user memory and 2 MB of non-volatile flash, the GE IC697CPU781 stores complex control programs and retains data during power outages, eliminating the need for battery backups. This is invaluable in remote locations like offshore platforms, where power interruptions are common but program integrity is essential.

With 512 KB of user memory and 2 MB of non-volatile flash, the GE IC697CPU781 stores complex control programs and retains data during power outages, eliminating the need for battery backups. This is invaluable in remote locations like offshore platforms, where power interruptions are common but program integrity is essential.

Flexible communication:

Dual serial ports (RS-232/RS-485) and a Genius bus interface support multiple protocols, enabling integration with HMIs (e.g., GE IC693HMI301), barcode scanners, and remote I/O racks. The Genius bus, operating at 1 Mbps, connects to distributed I/O modules like GE IC697MDL753, reducing wiring costs in large facilities such as steel mills.

Dual serial ports (RS-232/RS-485) and a Genius bus interface support multiple protocols, enabling integration with HMIs (e.g., GE IC693HMI301), barcode scanners, and remote I/O racks. The Genius bus, operating at 1 Mbps, connects to distributed I/O modules like GE IC697MDL753, reducing wiring costs in large facilities such as steel mills.

Redundant operation:

When paired with a second GE IC697CPU781 and IC697RNR701 module, the CPU supports hot standby redundancy, with automatic failover (<100 ms) during hardware faults. This eliminates single points of failure, a must for industries like nuclear power, where unplanned downtime could lead to safety risks or significant financial losses.

When paired with a second GE IC697CPU781 and IC697RNR701 module, the CPU supports hot standby redundancy, with automatic failover (<100 ms) during hardware faults. This eliminates single points of failure, a must for industries like nuclear power, where unplanned downtime could lead to safety risks or significant financial losses.

Rugged industrial design:

A conformal coating protects against dust, moisture, and chemical vapors, while the module’s vibration resistance (10–2000 Hz, 10 G rms) ensures reliability in harsh environments—from foundries with high ambient temperatures to mining facilities with constant vibration. Its wide operating temperature range (0°C to +60°C) adapts to diverse climates, from temperate factories to desert power plants.

A conformal coating protects against dust, moisture, and chemical vapors, while the module’s vibration resistance (10–2000 Hz, 10 G rms) ensures reliability in harsh environments—from foundries with high ambient temperatures to mining facilities with constant vibration. Its wide operating temperature range (0°C to +60°C) adapts to diverse climates, from temperate factories to desert power plants.

Seamless Series 90-70 integration:

The GE IC697CPU781 interfaces directly with Series 90-70 I/O modules (e.g., IC697ALG731 analog input, IC697MDL753 discrete output) via the rack backplane, enabling plug-and-play expansion. This compatibility simplifies system upgrades, allowing users to add modules without modifying existing wiring—a key advantage in retrofitting legacy systems.

The GE IC697CPU781 interfaces directly with Series 90-70 I/O modules (e.g., IC697ALG731 analog input, IC697MDL753 discrete output) via the rack backplane, enabling plug-and-play expansion. This compatibility simplifies system upgrades, allowing users to add modules without modifying existing wiring—a key advantage in retrofitting legacy systems.

Advanced diagnostics:

Front-panel LEDs (Power, Run, Fault, Redundancy Status) provide instant visual feedback, while built-in self-tests monitor CPU health, memory integrity, and bus communication. Faults are logged with timestamps, enabling technicians to trace issues like program errors or I/O module failures—reducing mean time to repair (MTTR) by up to 40% compared to older PLC models.

Front-panel LEDs (Power, Run, Fault, Redundancy Status) provide instant visual feedback, while built-in self-tests monitor CPU health, memory integrity, and bus communication. Faults are logged with timestamps, enabling technicians to trace issues like program errors or I/O module failures—reducing mean time to repair (MTTR) by up to 40% compared to older PLC models.

Application Areas

-

Manufacturing:

- Serves as the control core for packaging lines, regulating filling machines, sealers, and labelers based on sensor inputs to ensure consistent package quality.

- Manages batch mixing processes in chemical plants, executing recipes stored in memory to control ingredient dosing and mixing times, ensuring compliance with safety standards.

-

Power Generation:

- Controls auxiliary systems in coal-fired power plants, such as boiler feedwater pumps and ash handling conveyors, optimizing energy usage and reducing downtime.

- Integrates with turbine control systems to monitor generator load and adjust fuel supply, maintaining stable grid synchronization during fluctuating demand.

-

Oil and Gas:

- Manages pipeline pump stations, adjusting motor speeds based on pressure sensor data to prevent cavitation and ensure efficient oil/gas transport.

- Executes safety interlock logic in refineries, triggering valve closures via IC697MDL753 outputs when pressure or temperature exceeds safe limits.

-

Water/Wastewater:

- Automates treatment plant filtration systems, coordinating backwash cycles for sand filters based on differential pressure readings to maintain water quality.

- Controls pump stations in municipal water networks, adjusting operation to match demand peaks and reduce energy consumption.

-

Mining:

- Regulates conveyor belt systems in ore processing facilities, stopping operations immediately if a misalignment or overload is detected to prevent equipment damage.

Related Products

- GE IC697CHS791: 10-slot rack that houses GE IC697CPU781 and other Series 90-70 modules, providing mechanical support and backplane connectivity.

- GE IC697PSD750: 24 VDC power supply module that delivers stable power to GE IC697CPU781 and associated I/O modules.

- GE IC697MDL753: 32-point discrete output module actuated by GE IC697CPU781 to control valves, motors, and alarms in industrial systems.

- GE IC697ALG731: 8-channel analog input module whose sensor data (e.g., pressure, temperature) is processed by GE IC697CPU781 for closed-loop control.

- GE IC697RNR701: Redundancy module enabling hot standby operation between two GE IC697CPU781 CPUs, ensuring uninterrupted operation during faults.

- GE IC697BEM711: Genius bus controller that extends GE IC697CPU781’s reach to remote I/O racks, reducing wiring costs in large facilities.

- GE IC693HMI301: HMI panel that interfaces with GE IC697CPU781 for operator monitoring and manual control of industrial processes.

Installation and Maintenance

Pre-installation preparations: Before installing GE IC697CPU781, verify the IC697CHS791 rack is properly grounded to prevent electrostatic discharge (ESD). Use an ESD wrist strap during handling to protect sensitive components. Insert the CPU into the rack’s designated slot (typically slot 0), ensuring it seats firmly in the backplane. Connect external 24 VDC power to the rack via IC697PSD750, and attach communication cables to RS-232/RS-485 ports for HMI or peripheral connections. For redundant setups, install the second GE IC697CPU781 in slot 1 and connect the IC697RNR701 module to enable failover.

Maintenance suggestions: Perform monthly visual inspections of GE IC697CPU781 front-panel LEDs to confirm normal operation (green Run light, no Fault indicators). Clean dust from ventilation slots with compressed air quarterly to maintain cooling efficiency. Annually, back up the control program to external storage using Proficy PLC Programming Software, and update firmware to address compatibility issues with newer I/O modules. Test redundancy by powering down the primary CPU and verifying seamless switchover to the standby unit. Inspect backplane connections yearly for corrosion, especially in humid environments, to ensure reliable communication with I/O modules.

Product Guarantee

Our company offers a one-year quality warranty service for GE IC697CPU781, covering hardware malfunctions not caused by human factors. During the warranty period, if GE IC697CPU781 exhibits abnormal performance—such as processing delays, communication failures, or memory errors—we will provide replacement services. As a leading enterprise in the industrial control industry established in 2007, with 17 years of experience, we are an import and export trade distribution company specializing in major brands of industrial control parts. We maintain a large stock of unpopular and discontinued models, including GE IC697CPU781, and our global supply chain network allows us to quickly meet customers’ urgent needs for spare parts. Whether for routine replacements or hard-to-find components, we ensure reliable support to keep your industrial systems operating continuously and stably.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: