Description

GE IC693MDL340 Digital Input Module

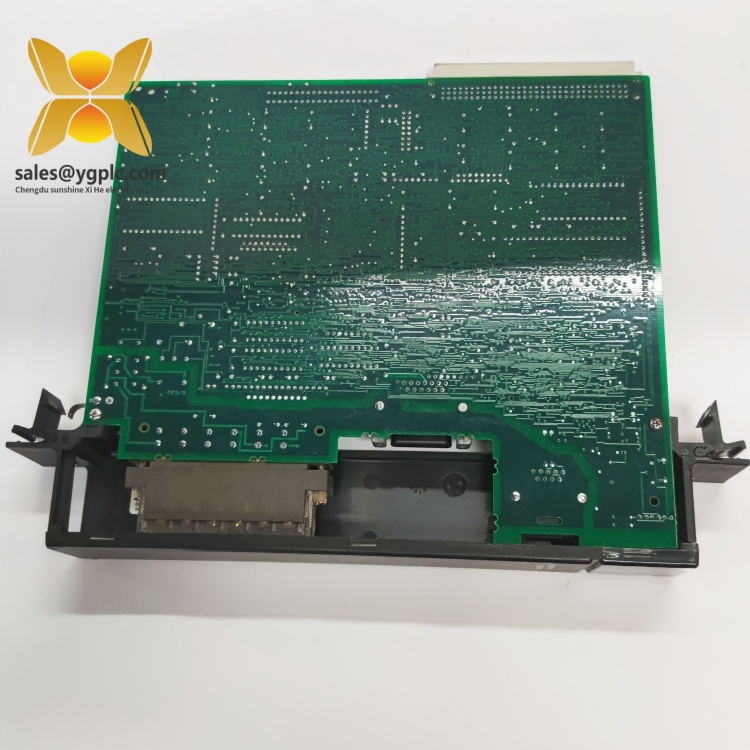

Product Overview: GE IC693MDL340

The GE IC693MDL340 digital input module is a high-reliability component designed for GE’s 90-30 Series PLC system, serving as a critical interface for converting field-level digital signals into process data for automation systems. As part of the IC693 family, this module supports 16 discrete input channels, each equipped with optical isolation to protect against electrical noise and transient spikes. The IC693MDL340 is engineered to withstand harsh industrial environments, making it ideal for applications requiring robust signal acquisition in manufacturing, power generation, and process control.

Featuring a 24V DC input voltage range and sink/source compatibility, the IC693MDL340 seamlessly interfaces with sensors, switches, and limit devices. Its hot-swappable design allows for module replacement without system shutdown, minimizing downtime in critical operations. The module’s LED status indicators provide real-time feedback on input states, while its high-density design (16 channels in a compact form factor) optimizes space in control cabinets. Within the 90-30 Series ecosystem, the IC693MDL340 acts as a bridge between field devices and the PLC processor, ensuring reliable data transmission for real-time control and monitoring.

Technical Specifications: GE IC693MDL340

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC693MDL340 |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Input Channels | 16 discrete inputs |

| Input Voltage | 24V DC (±10%) |

| Input Current | 10 mA per channel |

| Optical Isolation | 500V rms between inputs and logic |

| Physical Dimensions | 101.6 mm (H) × 152.4 mm (W) × 76.2 mm (D) |

| Weight | 0.9 kg |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (GE 90-30 Series) |

| Country of Origin | United States |

Main Features and Advantages: GE IC693MDL340

Rugged Electrical Isolation: The IC693MDL340 features 500V rms optical isolation per channel, protecting the PLC system from voltage spikes and electrical noise common in industrial environments. This isolation ensures signal integrity and prevents damage to internal components, enhancing system reliability.

Hot-Swappable Design: The module supports hot swapping, allowing replacement while the PLC system remains operational. This feature is critical for maintenance in continuous processes, reducing downtime and improving operational efficiency.

Real-Time Status Monitoring: Built-in LED indicators for each input channel provide immediate visual feedback on signal states, enabling quick troubleshooting and reducing diagnostic time. The LEDs also help identify faulty sensors or wiring issues without system downtime.

High-Density Configuration: With 16 input channels in a compact form factor, the IC693MDL340 optimizes space in control panels, making it suitable for both new installations and retrofitted systems where space is limited.

Wide Operating Range: The module’s ability to function from 0°C to +60°C and resist humidity ensures reliable performance in harsh industrial settings, including manufacturing plants, oil refineries, and outdoor installations.

Application Areas: GE IC693MDL340

The GE IC693MDL340 digital input module is widely used in industries requiring reliable digital signal acquisition:

- Manufacturing: Integrates with conveyor systems, robotic cells, and assembly lines to monitor limit switches, proximity sensors, and safety interlocks, ensuring precise control over production processes.

- Power Generation: Monitors circuit breaker status, valve positions, and motor starters in power plants, enabling real-time control of generation and distribution systems.

- Oil and Gas: Deployed in refineries and pipeline networks to acquire signals from pressure switches, flow sensors, and emergency shutdown (ESD) devices, supporting safety-critical operations.

- Water Treatment: Controls pumps, valves, and filters in water/wastewater plants by processing digital inputs from level sensors and flow meters, ensuring regulatory compliance.

- Material Handling: Interfaces with palletizers, stackers, and automated guided vehicles (AGVs) to manage load positioning and movement, enhancing warehouse efficiency.

Related Products: GE IC693MDL340

- GE IC693MDL645: A 16-point digital output module complementary to the IC693MDL340, providing relay-isolated outputs for controlling actuators and motors.

- GE IC693CPU360: A 90-30 Series processor module that works with the IC693MDL340 to execute control logic and process input data.

- GE IC693PWR330: A power supply module that ensures stable 24V DC delivery to the IC693MDL340 and other 90-30 Series components.

- GE IC693ALG222: An analog input module for integrating with the IC693MDL340 in systems requiring both digital and analog signal processing.

- GE IC693CHS392: A rack chassis that houses the IC693MDL340 and other modules, providing mechanical support and power distribution.

- GE IC693ACC300: A communication module that enables Ethernet connectivity for the IC693MDL340, facilitating remote monitoring and data logging.

Installation and Maintenance: GE IC693MDL340

Pre-installation Preparations:

Before installing the IC693MDL340, ensure the GE 90-30 Series rack is properly grounded and powered off. Verify that the input voltage (24V DC) matches the module’s requirements and that field wiring complies with GE’s specifications. Clean the rack slot and align the module with the guides, pushing it firmly into place until the retention clips engage. Connect the input wires to the terminal block, ensuring proper polarity and torque (1.2–1.5 N·m), and secure the wiring to prevent strain on the terminals.

Before installing the IC693MDL340, ensure the GE 90-30 Series rack is properly grounded and powered off. Verify that the input voltage (24V DC) matches the module’s requirements and that field wiring complies with GE’s specifications. Clean the rack slot and align the module with the guides, pushing it firmly into place until the retention clips engage. Connect the input wires to the terminal block, ensuring proper polarity and torque (1.2–1.5 N·m), and secure the wiring to prevent strain on the terminals.

Maintenance Recommendations:

- Routine Inspections: Monthly checks should include verifying LED status indicators, tightening terminal connections, and inspecting for physical damage or dust accumulation.

- Signal Testing: Quarterly testing of input channels using a calibrated signal source ensures each channel responds correctly to voltage inputs. Replace faulty channels promptly to maintain system reliability.

- Environmental Monitoring: Ensure the operating temperature stays within 0°C–60°C and humidity does not exceed 95%. Install additional cooling if necessary to prevent overheating.

- Firmware Management: Although the IC693MDL340 does not require firmware updates, consult GE’s documentation for any hardware revisions or compatibility notices with newer PLC processors.

Product Guarantee: GE IC693MDL340

Our company provides a 12-month quality warranty for the GE IC693MDL340 digital input module, covering hardware defects from non-human causes. During the warranty period, we will replace any module with faulty isolation, unresponsive inputs, or physical damage at no cost. For discontinued models or urgent needs, our global supply chain network ensures rapid delivery of scarce components, minimizing disruptions to your operations.

With 17 years of expertise in industrial control distribution, we are committed to reliable solutions and exceptional support. The IC693MDL340 exemplifies our dedication to quality, offering robust performance for critical automation needs. Contact us today to optimize your system with this trusted digital input module.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for GE’s official technical documentation.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IC693APU301 Digital output

GE IC693CHS391 Program module

GE IC693CHS392 Ethernet

GE IC693CMM321 Integrated protection device

GE IC693CPU331 Connecting module

GE IC693CPU341 driver

GE IC693CPU363 servo

GE IC693CPU372 Eddy current sensor

GE IC693CPU374 monitor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: