Description

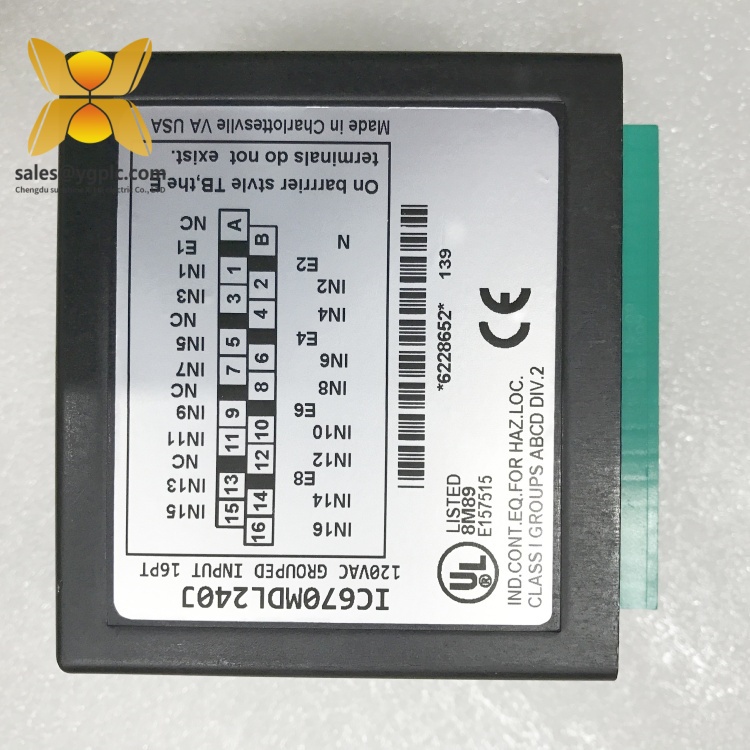

GE IC670MDL240J Digital Input Module

Product Overview

The GE IC670MDL240J is a high-performance Digital Input Module designed for GE’s 90-70 Series PLC platform, catering to industrial automation systems that demand reliable and precise signal acquisition. Engineered to convert discrete input signals from field devices (such as switches, sensors, and relays) into digital data for processing by the PLC, this module ensures robust operation in harsh industrial environments. As part of the IC670 Series, the IC670MDL240J offers seamless integration with other 90-70 Series components, including CPU modules and output modules, enabling scalable control solutions for manufacturing, power generation, and process industries.

Featuring a rugged industrial design, the GE IC670MDL240J supports 16 isolated digital input channels, each capable of handling 24 V DC signals with high noise immunity. Its optically isolated inputs protect the PLC from voltage spikes and ground loops, ensuring signal integrity even in high-interference environments. The module’s LED indicators provide real-time status feedback for each channel, simplifying troubleshooting and maintenance. With an operating temperature range of -40°C to +70°C and compliance with industry standards like IEC 61131-2, the IC670MDL240J is ideal for applications requiring continuous operation in challenging settings, such as offshore platforms, refineries, and heavy machinery installations.

In automation ecosystems, the IC670MDL240J serves as a critical interface between field devices and the PLC, translating physical switch states or sensor outputs into digital commands. Its hot-swappable design allows for module replacement without system shutdown, minimizing downtime during maintenance. By combining high-density input channels with advanced diagnostic capabilities, this module enhances system efficiency and reduces overall lifecycle costs, making it a cornerstone of reliable industrial control strategies.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670MDL240J |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Platform | 90-70 Series PLC |

| Input Channels | 16 isolated channels |

| Input Voltage | 24 V DC ±10% |

| Signal Type | Discrete (TTL/CMOS compatible) |

| Response Time | ≤5 ms |

| Isolation | 250 V RMS optical isolation per channel |

| Physical Dimensions | 177.8 mm (H) × 101.6 mm (W) × 127 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to +70°C |

| Mounting | DIN rail or panel-mounted |

| Certifications | CE, UL, cUL |

Key Features and Advantages

High-Density Signal Acquisition: The IC670MDL240J accommodates 16 digital input channels in a compact form factor, optimizing space in control panels for applications requiring multiple signal monitoring, such as conveyor systems or robotic cells.

Optical Isolation for Reliability: Each input channel features 250 V RMS optical isolation, safeguarding the PLC from electrical transients and ground loops. This design ensures stable signal transmission in environments with high electromagnetic interference, such as near motors or power lines.

Real-Time Diagnostic Capabilities: LED indicators for each channel provide instant visual feedback on signal status (on/off), while built-in diagnostic circuitry monitors for open circuits, short circuits, and signal degradation. This proactive monitoring reduces troubleshooting time and enhances system availability.

Hot-Swap Functionality: The module can be replaced while the PLC is operational, allowing maintenance without disrupting critical processes. This feature is invaluable for 24/7 industrial operations where downtime translates to lost productivity.

Wide Environmental Tolerance: Engineered to withstand extreme temperatures, vibration, and humidity, the IC670MDL240J ensures reliable performance in harsh conditions. Its rugged enclosure and conformal-coated circuitry protect against dust, moisture, and corrosive elements.

Seamless System Integration: Compatible with GE’s 90-70 Series PLCs and programming tools (e.g., Cimplicity), the module simplifies configuration and integration. It supports daisy-chaining with other IC670 modules, enabling scalable solutions for small to large control systems.

Application Areas

The GE IC670MDL240J is widely deployed in industries requiring precise discrete signal monitoring:

- Manufacturing: Monitors limit switches, proximity sensors, and safety interlocks in automotive assembly lines, food processing plants, and pharmaceutical facilities, ensuring process consistency and operator safety.

- Power Generation: Tracks breaker states, valve positions, and auxiliary system status in thermal and renewable energy plants, supporting seamless grid integration and equipment protection.

- Oil & Gas: Controls wellhead sensors, pipeline pressure switches, and refinery safety interlocks, enabling safe and efficient production operations in upstream, midstream, and downstream sectors.

- Water/Wastewater Treatment: Monitors level switches, flow meters, and pump status in treatment plants, adapting to fluctuating demand and ensuring regulatory compliance.

- Material Handling: Manages conveyor belt alignment, hoist position sensors, and automated storage systems in logistics centers, optimizing throughput and reducing manual intervention.

Specific applications include:

- Safety Instrumented Systems (SIS): Integrates with emergency stop buttons and safety switches to trigger shutdowns in hazardous situations, meeting SIL safety standards.

- Machine Condition Monitoring: Captures status signals from vibration sensors and temperature switches, enabling predictive maintenance of rotating equipment.

- Process Automation: Coordinates with pushbuttons and selector switches in control panels to manage production line sequencing and quality control.

Related Products

- IC670MDL241J Digital Input Module: A 32-channel variant of the IC670MDL240J, offering higher input density for large-scale control applications.

- IC670ALG222 Analog Input Module: Complements the IC670MDL240J by providing analog data acquisition for mixed-signal control systems.

- IC670CPU780J CPU Module: High-performance processor for 90-70 Series PLCs, coordinating control logic for the IC670MDL240J and other I/O modules.

- IC670PWR720J Power Supply Module: Provides redundant 24 V DC power for 90-70 Series racks, ensuring uninterrupted operation of the IC670MDL240J.

- IC670CBL701J Rack Cable: Connects the IC670MDL240J to the CPU module, ensuring reliable data transmission within the PLC rack.

- IC670MDL740J Digital Output Module: Works in tandem with the IC670MDL240J to form complete control loops, driving actuators and relays based on input signals.

- IC670ACC700J Communication Module: Enables Ethernet connectivity for the IC670MDL240J, supporting remote monitoring via SCADA systems or cloud platforms.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IC670MDL240J, ensure the 90-70 Series rack is properly grounded and powered. Verify that the module’s input voltage (24 V DC) matches the connected field devices. Use shielded cables for field wiring to minimize electromagnetic interference, routing power and signal cables separately to avoid noise. Mount the module on a DIN rail or panel using the provided hardware, leaving sufficient space for heat dissipation. Configure the module in GE’s Cimplicity software, assigning channel addresses and enabling diagnostic features as needed.

Before installing the GE IC670MDL240J, ensure the 90-70 Series rack is properly grounded and powered. Verify that the module’s input voltage (24 V DC) matches the connected field devices. Use shielded cables for field wiring to minimize electromagnetic interference, routing power and signal cables separately to avoid noise. Mount the module on a DIN rail or panel using the provided hardware, leaving sufficient space for heat dissipation. Configure the module in GE’s Cimplicity software, assigning channel addresses and enabling diagnostic features as needed.

Maintenance Suggestions:

- Routine Inspections: Perform monthly checks to verify LED status indicators and ensure all connections are secure. Use Cimplicity to review module diagnostics for any fault codes, such as signal loss or isolation failure.

- Environmental Maintenance: Quarterly, clean the module’s vents and enclosure to prevent dust accumulation, which can lead to overheating. Ensure the control panel’s environmental controls (e.g., fans, filters) are functioning properly.

- Functional Testing: Annually, test each input channel using a precision signal source to confirm response time and isolation integrity. Replace any channels that fail to meet specifications to prevent unexpected system disruptions.

- Firmware Management: Periodically update the PLC’s firmware to incorporate bug fixes and compatibility improvements, following GE’s recommended procedures to avoid configuration errors.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IC670MDL240J, covering hardware defects under normal use. In the event of performance issues, such as signal inaccuracies or channel failures, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the IC670MDL240J, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering reliable solutions to maintain your control system’s integrity.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IC660EBD020 Expansion module

GE IC660EBD025 RXM rack

GE IC660ELB912 Thermoelectric couple

GE IC660ELB912G Double-action switch

GE IC660TBA026 DC/DC

GE IC660TBD024 Analog output module

GE IC660TBD025 display

GE IC660TSA100 Relay output

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: