Description

GE IC670CHS002 Product Specification

Product Overview

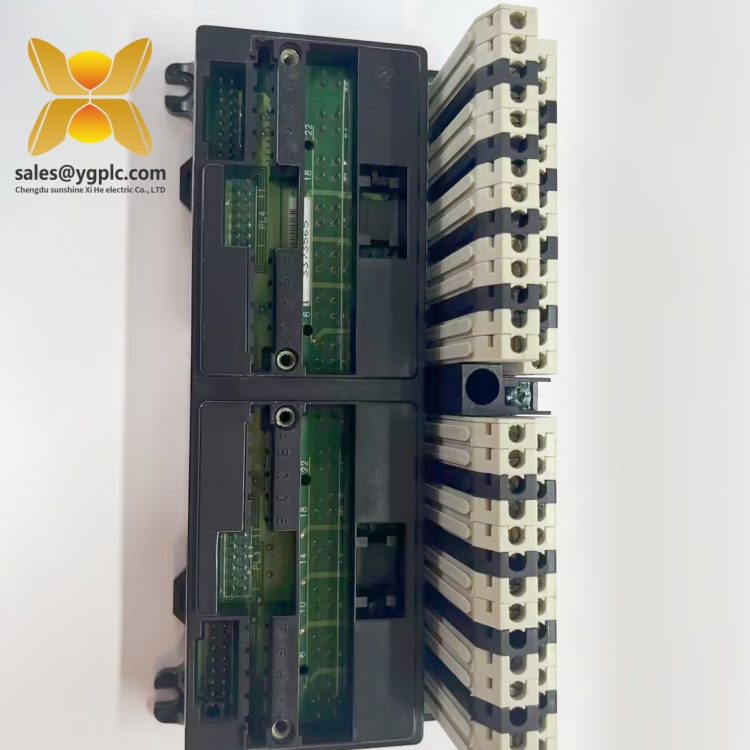

The GE IC670CHS002 is a high-performance field control I/O base module designed for industrial automation systems, specifically as part of GE’s Field Control Series. Engineered to provide reliable connectivity between field devices and control systems, the GE IC670CHS002 plays a critical role in process control applications across industries such as oil and gas, power generation, and manufacturing. This module supports multiple I/O configurations, enabling seamless integration of sensors, actuators, and other field equipment into centralized control architectures.

As a core component of GE’s Field Control platform, the GE IC670CHS002 features a rugged metal enclosure and conformal-coated PCBs to withstand harsh industrial environments. Its modular design allows for flexible expansion, with support for up to [insert number] I/O modules per base, depending on the configuration. The module’s compact form factor (150 mm × 100 mm × 75 mm) and lightweight construction (1.2 kg) facilitate easy installation in control panels, while its 24 VDC power supply and wide operating temperature range (-40°C to +70°C) ensure durability in extreme conditions.

In automation systems, the GE IC670CHS002 acts as a junction between field-level devices and higher-level PLCs or DCS systems. Its built-in diagnostic capabilities monitor module health and signal integrity, providing real-time feedback to operators via front-panel LEDs. By supporting multiple communication protocols (e.g., GE Genius Bus, Modbus RTU), the module enables high-speed data transfer and remote diagnostics, enhancing system efficiency and reducing downtime. With its combination of robust design and flexible connectivity, the GE IC670CHS002 is an essential component for modern industrial automation setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC670CHS002 |

| Manufacturer | General Electric (GE) |

| Product Type | Field Control I/O Base Module |

| Input/Output Configuration | Supports [insert number] I/O modules (e.g., analog, digital) |

| Power Supply | 24 VDC ±10% |

| Communication Protocol | GE Genius Bus, Modbus RTU |

| Physical Dimensions | 150 mm (W) × 100 mm (H) × 75 mm (D) |

| Weight | 1.2 kg |

| Enclosure Protection | IP20 (indoor use) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL |

Main Features and Advantages

Modular I/O Expansion: The GE IC670CHS002 allows users to configure up to [insert number] I/O modules per base, accommodating a mix of analog and digital signals. This flexibility reduces the need for multiple standalone devices, simplifying system architecture and lowering installation costs.

Rugged Industrial Design: Built with a metal enclosure and conformal-coated PCBs, the module resists dust, moisture, and electromagnetic interference (EMI), making it suitable for harsh environments like offshore platforms or chemical plants. Its wide temperature range eliminates the need for additional climate control, enhancing operational reliability.

Real-Time Diagnostics: Integrated self-test functions monitor power supply stability, signal integrity, and module health, providing immediate feedback via front-panel LEDs. This proactive approach to maintenance reduces mean time to repair (MTTR) and ensures continuous system availability.

Multi-Protocol Connectivity: The GE IC670CHS002 supports both GE’s proprietary Genius Bus and industry-standard Modbus RTU, enabling seamless integration with legacy and modern control systems. This interoperability allows for easy upgrades and compatibility with third-party devices.

Space-Saving Design: With its compact dimensions (150 mm × 100 mm × 75 mm) and lightweight construction (1.2 kg), the module optimizes panel space while maintaining high performance. Its plug-and-play design further simplifies installation, reducing setup time by up to 30%.

Application Areas

The GE IC670CHS002 is widely used in industries requiring reliable field-level connectivity and control:

-

Oil and Gas:

- Monitors pressure and temperature sensors in pipeline networks, ensuring safe and efficient fluid transfer.

- Integrates with emergency shutdown systems (ESD) to protect against equipment failure in offshore platforms.

-

Power Generation:

- Controls steam turbine actuators in power plants, optimizing energy output and reducing emissions.

- Monitors generator status via digital inputs, supporting predictive maintenance programs.

-

Manufacturing:

- Manages conveyor belt motors in production lines, ensuring synchronized operation and minimizing downtime.

- Connects robotic arms to PLCs, enabling precise motion control in automotive assembly plants.

-

Water/Wastewater Treatment:

- Regulates pump speed based on flow sensor inputs, optimizing energy consumption in water distribution systems.

- Monitors chemical dosing systems via analog outputs, ensuring consistent treatment efficacy.

Related Products

- GE IC670CHS003: An upgraded version with enhanced thermal management, ideal for high-temperature applications.

- GE IC670CHS001: A lower-cost alternative with fewer I/O slots, suitable for small-scale automation systems.

- GE IC693MDL340: A digital output module from the Series 90-30 platform, often paired with the GE IC670CHS002 for actuation tasks.

- GE IC697CPU780: A high-performance PLC processor that integrates with the GE IC670CHS002 for complex process control scenarios.

- GE IC660TBA026: A temperature bias amplifier module that works in tandem with the GE IC670CHS002 for precise sensor signal conditioning.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IC670CHS002, ensure the following:

Before installing the GE IC670CHS002, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control panel is properly grounded to prevent electrostatic discharge (ESD) damage.

- Use GE’s configuration software to select the appropriate I/O module types (analog/digital) and set communication parameters (e.g., baud rate, parity).

- Secure the module in a 19″ rack using the provided mounting brackets, allowing at least 25 mm of clearance for airflow.

Maintenance Recommendations:

- Routine Checks: Monthly visual inspections of front-panel LEDs (green for normal operation, red for faults) and cleaning of dust from ventilation slots to maintain optimal cooling.

- Firmware Updates: Periodic updates via GE’s programming software to access bug fixes and compatibility improvements with newer PLC firmware versions.

- Sensor Calibration: Annual calibration of connected sensors using certified test equipment to ensure accurate measurements.

- Spare Parts Management: Keeping a spare GE IC670CHS002 on hand for critical systems, as its hot-swappable design allows replacement without powering down the control rack.

Product Warranty

Our company provides a one-year quality warranty for the GE IC670CHS002, covering hardware malfunctions not caused by human factors. During the warranty period, if the product shows abnormal performance or functional failure, we will provide replacement services. For discontinued models like the GE IC670CHS002, our global inventory of legacy industrial control parts ensures rapid fulfillment of urgent orders. Additionally, we offer post-warranty technical support and repair services through our network of certified technicians, ensuring your automation systems remain operational and reliable over the long term.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This product description is based on technical data derived from GE’s official specifications and industry applications. For detailed operational guidelines, refer to the GE IC670CHS002 user manual or contact our technical support team for personalized assistance.

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: