Description

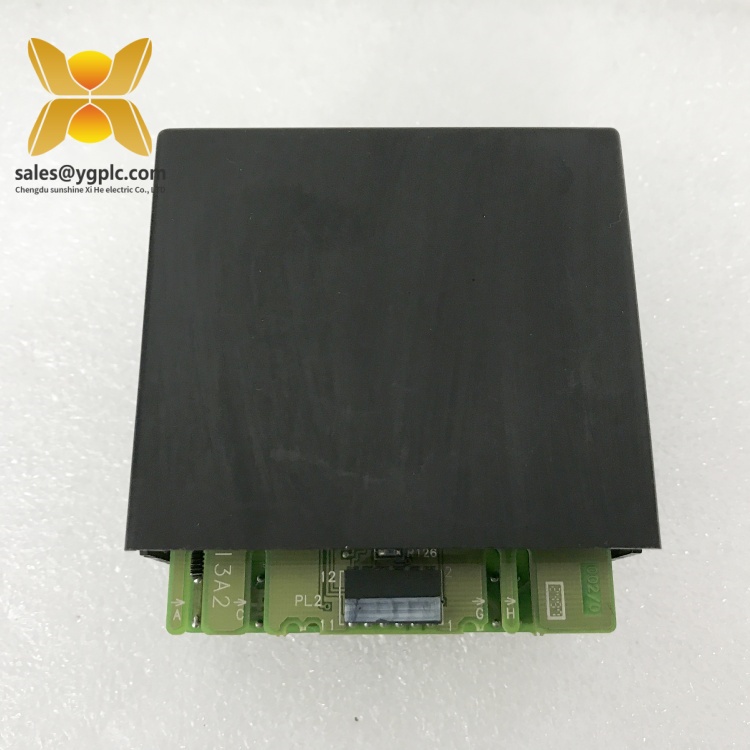

GE IC660ELB912G I/O Module

Product Overview: GE IC660ELB912G

The GE IC660ELB912G I/O module is a high-performance industrial automation component designed for seamless integration into GE’s Series 660 programmable logic controller (PLC) systems. As a key component of this advanced platform, the IC660ELB912G serves as a versatile interface for connecting field devices to the PLC, enabling real-time data exchange between sensors, actuators, and the control system. This module is engineered to deliver reliable input/output (I/O) functionality in harsh industrial environments, combining robust hardware with flexible configuration options to meet diverse automation needs.

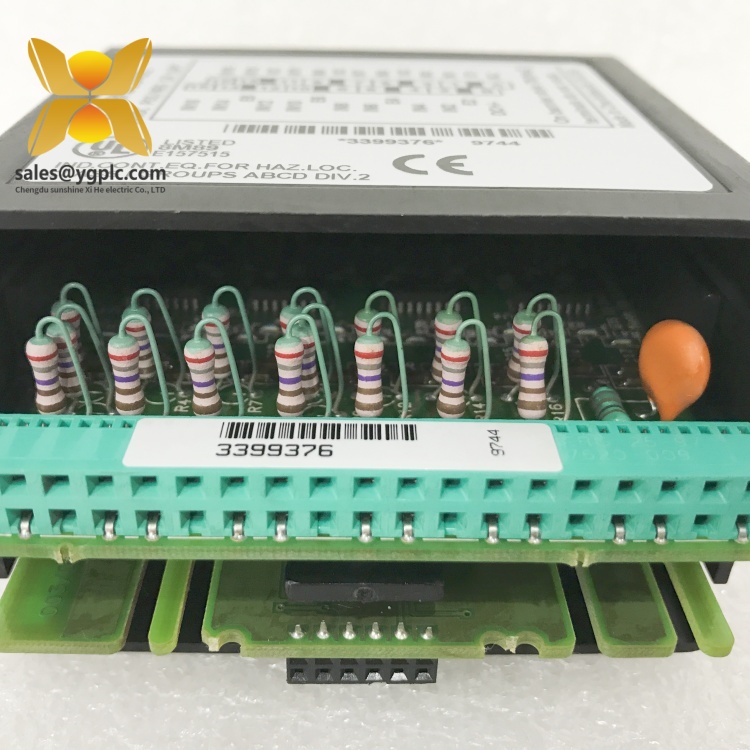

Featuring 16 isolated digital input channels, the IC660ELB912G accepts voltage signals ranging from 24V DC to 120V AC, making it compatible with a wide range of field devices. Its screw-type terminal block connections ensure secure wiring, while the module’s hot-swappable design allows for replacement without powering down the system, minimizing downtime. The IC660ELB912G integrates seamlessly with other Series 660 components, such as the IC660BBD010 CPU module, forming a comprehensive automation solution for process control and machine automation.

In automation systems, the IC660ELB912G plays a critical role in translating physical signals from sensors (e.g., limit switches, proximity detectors) into digital data for the PLC to process. Its LED status indicators provide real-time feedback on input states, enabling quick diagnostics and troubleshooting. With a wide operating temperature range (-40°C to +70°C) and IP20 protection rating, this module withstands dust, vibration, and electromagnetic interference, ensuring reliable performance in manufacturing plants, power stations, and industrial facilities.

Technical Specifications: GE IC660ELB912G

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660ELB912G |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Input Channels | 16 isolated channels |

| Input Voltage Range | 24V DC to 120V AC |

| Contact Rating | 5mA to 10mA @ rated voltage |

| Isolation | Optical isolation (2500V rms) |

| Physical Dimensions | 100 mm (H) × 80 mm (W) × 60 mm (D) |

| Weight | 0.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | DIN rail or panel-mounted |

| Communication Protocol | Proprietary (compatible with Series 660) |

| Country of Origin | United States |

Main Features and Advantages: GE IC660ELB912G

Wide Voltage Compatibility: The IC660ELB912G supports a broad input voltage range (24V DC to 120V AC), eliminating the need for multiple module types and simplifying inventory management. This versatility makes it suitable for diverse applications, from low-voltage sensor networks to high-voltage industrial setups.

Rugged Industrial Design: Built with industrial-grade components, the module features optical isolation (2500V rms) to protect against electrical surges and noise. Its robust construction and wide temperature tolerance ensure reliable operation in harsh environments, including those with high vibration or extreme temperatures.

Hot-Swappable Functionality: The module’s hot-swappable design allows for replacement while the system is running, the need for system shutdowns during maintenance. This feature enhances operational continuity, particularly in critical processes where downtime is costly.

Easy Installation and Configuration: With screw-type terminal blocks and a user-friendly design, the IC660ELB912G simplifies wiring and setup. It integrates seamlessly with GE’s Series 660 programming software, enabling quick configuration of input parameters and diagnostics.

Real-Time Status Monitoring: Built-in LED indicators provide instant visibility into input channel states, facilitating rapid troubleshooting and reducing mean time to repair (MTTR). This feature is invaluable for maintaining system efficiency in fast-paced manufacturing environments.

Application Areas: GE IC660ELB912G

The GE IC660ELB912G I/O module is widely applied in industries requiring reliable digital signal processing:

- Manufacturing: Used in assembly lines to monitor limit switches, proximity sensors, and safety interlocks, ensuring precise control over production processes. For example, in automotive plants, the module tracks conveyor belt positions and triggers alarms for misalignments.

- Power Generation: Deployed in power stations to monitor circuit breaker states, relay signals, and switchgear positions, supporting real-time control of generators and substations.

- Oil and Gas: Installed in refineries and pipeline systems to interface with pressure switches, flow sensors, and emergency shutdown (ESD) signals, enhancing safety and process efficiency.

- Water Treatment: Manages input signals from level sensors, pressure transducers, and flow meters in water/wastewater plants, enabling automated control of pumps and valves.

- Material Handling: Integrates with conveyor systems, robotic arms, and storage equipment in warehouses, providing real-time feedback on load positions and equipment status.

Related Products: GE IC660ELB912G

- GE IC660BBD010: A Series 660 CPU module that serves as the central processing unit, working in tandem with the IC660ELB912G to execute control logic.

- GE IC660ELA910G: An analog input module that complements the IC660ELB912G by processing continuous signals from temperature or pressure sensors.

- GE IC660ELC912G: A digital output module with 16 channels, enabling control of actuators and relays in conjunction with the IC660ELB912G.

- GE IC660ELH912G: A high-density I/O module with 32 channels, suitable for large-scale systems requiring extensive input monitoring.

- GE IC660PWR001: A power supply module for the Series 660 system, ensuring stable power delivery to the IC660ELB912G and other components.

- GE IC660ALG001: A logic module that expands the computational capabilities of the system when paired with the IC660ELB912G.

Installation and Maintenance: GE IC660ELB912G

Pre-installation Preparations:

Before installing the IC660ELB912G, ensure the control cabinet is properly grounded and ventilated. Verify that the input voltage (24V DC to 120V AC) matches the module’s specifications and that all field devices are compatible. Mount the module on a DIN rail or panel using the provided brackets, leaving adequate space for heat dissipation. Connect the power cables to the designated terminals and wire field devices to the input channels, following GE’s wiring diagrams to ensure correct polarity and isolation.

Before installing the IC660ELB912G, ensure the control cabinet is properly grounded and ventilated. Verify that the input voltage (24V DC to 120V AC) matches the module’s specifications and that all field devices are compatible. Mount the module on a DIN rail or panel using the provided brackets, leaving adequate space for heat dissipation. Connect the power cables to the designated terminals and wire field devices to the input channels, following GE’s wiring diagrams to ensure correct polarity and isolation.

Maintenance Recommendations:

- Routine Inspections: Monthly checks should include verifying LED indicators for abnormal input states, tightening terminal connections, and cleaning the module’s surface to prevent dust accumulation.

- Functional Testing: Quarterly testing of input channels using a calibrated signal source ensures accurate signal reception. Replace any faulty channels promptly to maintain system reliability.

- Firmware Updates: Periodically update the module’s firmware via GE’s programming software to access bug fixes and compatibility improvements.

- Spare Parts Management: Keep a spare IC660ELB912G on hand for quick replacement, leveraging our global supply chain for rapid delivery of discontinued or urgent components.

Product Guarantee: GE IC660ELB912G

Our company provides a 12-month quality warranty for the GE IC660ELB912G I/O module, covering hardware defects arising from non-human factors. During the warranty period, we will replace any module that exhibits faulty input processing, isolation failure, or physical damage at no additional cost. For discontinued models or urgent repair needs, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing downtime and supporting continuous operation of your industrial systems.

With 17 years of expertise in industrial control distribution, we are committed to delivering reliable solutions that enhance productivity and reduce operational costs. The IC660ELB912G exemplifies our dedication to quality, offering the durability and performance required for critical automation tasks. Contact us today to discuss how this module can optimize your industrial control system.

Note: All product names, logos, and brands are the property of their respective owners. This document is for informational purposes only and does not substitute for GE’s official technical documentation. Always refer to the manufacturer’s guidelines for detailed installation and operation instructions.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: