Description

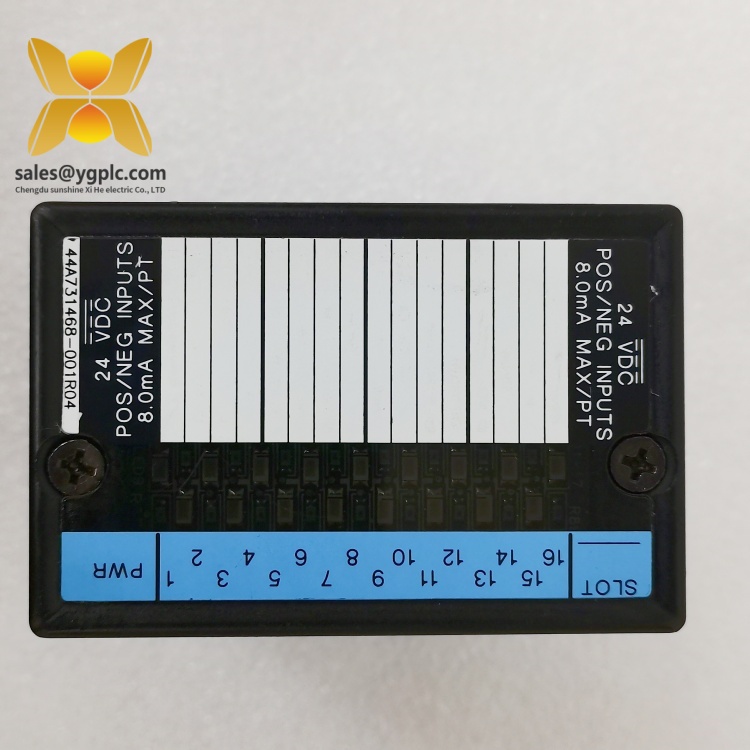

GE IC660ELB912 Mark I Series Logic Module

Product Overview

The GE IC660ELB912 is a high-reliability Logic Module designed as a core component of GE’s Mark I Series programmable logic controller (PLC) platform, catering to industrial automation applications that require robust control and monitoring capabilities. Engineered to execute sequential logic and control algorithms, this module serves as the brain of automation systems in industries such as manufacturing, power generation, and material handling, where precise and reliable operation is essential for process efficiency. The IC660ELB912 integrates seamlessly with other Mark I Series components, including input/output (I/O) modules and operator interfaces, forming a comprehensive control solution for both simple and complex industrial processes.

As part of the Mark I Series, the GE IC660ELB912 features a rugged design that withstands harsh industrial environments, including high temperatures, vibration, and electromagnetic interference. It supports ladder logic programming, a standard language in PLC applications, enabling engineers to develop and implement control strategies efficiently. The module’s non-volatile memory preserves program data during power outages, ensuring consistent operation and minimizing restart delays. With its modular architecture, the IC660ELB912 allows for easy expansion of I/O capacity and system functionality, making it a versatile choice for both new installations and retrofitted automation systems.

In industrial automation ecosystems, the IC660ELB912 serves as the central processing unit, receiving input signals from sensors, executing control logic, and driving output devices such as motors and valves. Its compatibility with GE’s programming software ensures intuitive configuration and diagnostics, reducing engineering time and enhancing maintainability. By delivering reliable performance and deterministic control, the GE IC660ELB912 optimizes production processes, minimizes downtime, and supports the continuous operation of critical industrial systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660ELB912 |

| Manufacturer | GE |

| Product Type | Logic Module (PLC CPU) |

| Processor | 16-bit microprocessor |

| Memory | 8 KB user program memory, 4 KB data memory |

| I/O Capacity | Supports up to 256 I/O points (with expansion modules) |

| Communication Interfaces | RS-232, RS-485 (optional) |

| Power Supply | 120/240 V AC, 50/60 Hz |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | 0°C to +60°C |

| Mounting | Panel-mounted or DIN rail |

| Certifications | CE, UL |

Key Features and Advantages

Reliable Logic Processing: The IC660ELB912 executes ladder logic programs with high precision, ensuring accurate control of industrial processes. Its 16-bit processor handles complex logic operations efficiently, making it suitable for applications that require real-time decision-making, such as conveyor systems or machine tool control.

Modular Expansion Capability: The module supports seamless integration with GE’s Mark I Series I/O modules (e.g., analog input/output, digital input/output), allowing users to scale their control systems as process requirements evolve. This modularity reduces upfront costs and enables future upgrades without replacing the entire PLC.

Non-Volatile Memory: Equipped with battery-backed RAM, the IC660ELB912 retains program data and configuration settings during power interruptions, eliminating the need for manual reprogramming and ensuring quick system restarts. This feature is critical for maintaining productivity in environments with unstable power supplies.

User-Friendly Programming: Compatible with GE’s proprietary programming software, the module allows engineers to develop, test, and deploy control logic intuitively. The software’s graphical interface simplifies troubleshooting and maintenance, reducing the learning curve for new users.

Robust Industrial Design: Built to withstand harsh operating conditions, the IC660ELB912 meets rigorous industry standards for vibration, shock, and temperature tolerance. Its durable enclosure protects internal components from dust, moisture, and electromagnetic interference, ensuring reliable performance in manufacturing plants, power stations, and other industrial settings.

Cost-Effective Solution: As a legacy component of GE’s Mark I Series, the IC660ELB912 offers a cost-effective alternative for maintaining and upgrading older automation systems. Its compatibility with existing infrastructure reduces the need for complete system overhauls, making it an ideal choice for budget-conscious projects.

Application Areas

The GE IC660ELB912 is widely used in industries that rely on reliable and straightforward automation control:

- Manufacturing: Controls assembly lines, robotic arms, and material handling systems in automotive, electronics, and food & beverage facilities, ensuring consistent production quality and efficiency.

- Power Generation: Manages auxiliary systems in power plants, such as cooling fans, fuel feeders, and water treatment processes, supporting the reliable operation of generators and turbines.

- Material Handling: Operates conveyor belts, cranes, and lifts in warehouses and distribution centers, optimizing logistics and reducing manual intervention.

- Water/Wastewater Treatment: Controls pumps, valves, and filtration systems in water treatment plants, ensuring the consistent delivery of clean water and the efficient treatment of wastewater.

Specific applications include:

- Machine Control: Directs the operation of CNC machines, presses, and other manufacturing equipment, ensuring precise movement and process timing.

- Packaging Systems: Controls the filling, sealing, and labeling processes in packaging lines, maintaining production speed and product integrity.

- Building Automation: Manages heating, ventilation, and air conditioning (HVAC) systems in commercial buildings, optimizing energy consumption and indoor comfort.

Related Products

- IC660BBD011 (Digital Input Module): Works with the IC660ELB912 to receive discrete signals from switches and sensors, expanding the module’s input capacity.

- IC660BBD021 (Digital Output Module): Enables the IC660ELB912 to drive relays and solenoids, converting logic signals into physical actions.

- IC660BBA010 (Analog Input Module): Allows the IC660ELB912 to process continuous signals from temperature and pressure sensors, supporting more complex control strategies.

- IC660BBA020 (Analog Output Module): Enables the IC660ELB912 to control variable-speed drives and analog valves, providing precise output regulation.

- IC660ELB932 (Expansion Logic Module): Extends the processing capacity of the IC660ELB912 in large-scale systems, supporting higher I/O counts and more complex logic.

- IC660CBL001 (Communication Cable): Facilitates data transfer between the IC660ELB912 and programming devices or operator interfaces, ensuring seamless system configuration.

- IC660PWR001 (Power Supply Module): Provides reliable power to the IC660ELB912 and associated I/O modules, ensuring stable operation in industrial environments.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IC660ELB912, ensure the control panel is properly grounded and ventilated. Verify the power supply compatibility (120/240 V AC) and mount the module securely using the provided brackets. Connect the module to I/O modules and programming devices using shielded cables to minimize electromagnetic interference. Use GE’s programming software to configure the module’s address, communication parameters, and control logic, ensuring that all settings match the specific application requirements.

Before installing the GE IC660ELB912, ensure the control panel is properly grounded and ventilated. Verify the power supply compatibility (120/240 V AC) and mount the module securely using the provided brackets. Connect the module to I/O modules and programming devices using shielded cables to minimize electromagnetic interference. Use GE’s programming software to configure the module’s address, communication parameters, and control logic, ensuring that all settings match the specific application requirements.

Maintenance Suggestions:

- Routine Inspections: Regularly check the module’s status indicators to ensure proper operation. Clean the enclosure and ventilation slots to prevent dust accumulation, which can affect thermal performance.

- Firmware Updates: Although the IC660ELB912 is a legacy product, apply any available firmware updates to address known issues and enhance compatibility with modern programming tools.

- Battery Replacement: Replace the module’s backup battery every 3–5 years to prevent data loss during power outages. Follow GE’s guidelines to ensure proper battery installation and data preservation.

- Spare Parts Management: Keep spare IC660ELB912 modules and key components on hand to minimize downtime in case of failures. Store spares in a dry, cool environment free from extreme temperatures and humidity.

Product Guarantee

Our company offers a 12-month quality warranty for the GE IC660ELB912, covering hardware defects under normal operating conditions. If the module experiences abnormal performance or functional failure during the warranty period, we will provide prompt replacement services. As a leading distributor in the industrial control industry, we leverage our global supply chain network to source rare and discontinued components, ensuring quick availability for urgent replacement needs. Our technical support team is dedicated to assisting with installation, programming, and troubleshooting, providing reliable services to maintain the continuous operation of your industrial automation systems.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE SLN080 IC086SLN080-A Optical fiber interface board

GE VMIACC-5595-208 350-805595-208N Acquisition card

GE VMIVME2540 Gas turbine card

GE SR489-P1-HI-A20-E FIM card

GE IC200PWR101D Input module

GE IC200PWB001A AI/AO/DI/DO module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: