Description

GE IC660EBD025 Product Specification

Product Overview

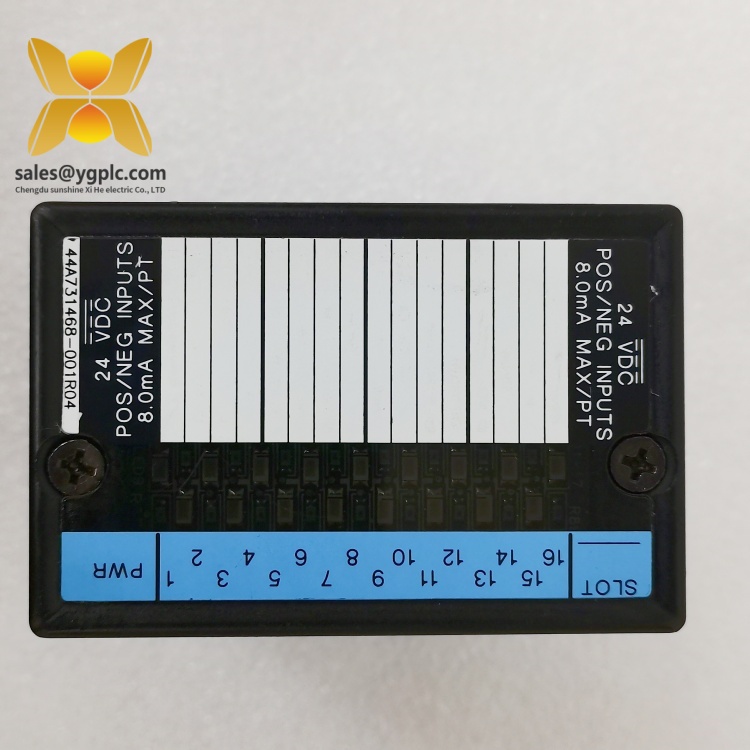

The GE IC660EBD025 is a high-reliability 16-channel digital input module designed for GE’s Series 600 Programmable Logic Controller (PLC) platform. Engineered to deliver precise and stable signal acquisition in industrial automation systems, this module serves as a critical interface between field devices (such as switches, sensors, and limit switches) and the PLC controller. The GE IC660EBD025 is built to withstand harsh industrial environments, making it an ideal choice for industries such as manufacturing, power generation, and oil and gas, where reliable data input is essential for process control and monitoring.

As part of GE’s renowned Series 600 PLC family, the GE IC660EBD025 supports 16 isolated digital input channels, each capable of handling 24 VDC signals with a noise immunity rating of 1,500 VAC. Its modular design allows for easy integration into GE’s rack-mounted PLC systems, enabling seamless expansion of input capabilities as operational needs evolve. The module features LED indicators for each channel, providing real-time status feedback to simplify troubleshooting and maintenance. With a compact form factor (114 mm × 127 mm × 102 mm) and lightweight construction (0.9 kg), the GE IC660EBD025 optimizes space in control cabinets while delivering robust performance.

In automation systems, the GE IC660EBD025 acts as a frontline data acquisition component, converting discrete field signals into digital data that the PLC can process. Its isolated channels protect the controller from voltage spikes and electrical noise, ensuring accurate and consistent signal transmission. By integrating with GE’s Proficy Machine Edition software, engineers can configure input parameters, set up diagnostic alerts, and monitor channel health remotely, enhancing system efficiency and reducing downtime. The GE IC660EBD025’s combination of rugged hardware and advanced signal processing makes it a cornerstone of reliable industrial control solutions.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC660EBD025 |

| Manufacturer | General Electric (GE) |

| Product Type | 16-Channel Digital Input Module (24 VDC) |

| Input Voltage | 24 VDC ±10% |

| Input Channels | 16 isolated channels |

| Signal Type | Discrete digital (NPN/PNP compatible) |

| Noise Immunity | 1,500 VAC (common mode), 1,000 VAC (differential mode) |

| Response Time | 5 ms (input to logic state change) |

| Physical Dimensions | 114 mm (W) × 127 mm (H) × 102 mm (D) |

| Weight | 0.9 kg |

| Operating Temperature | 0°C to +60°C |

| Humidity | 5% to 95% non-condensing |

| Installation | Rack-mounted (compatible with GE Series 600 racks) |

| Certifications | CE, UL, CSA |

Main Features and Advantages

High-Density Signal Acquisition: The GE IC660EBD025 houses 16 isolated digital input channels, allowing for simultaneous monitoring of multiple field devices. This high-density design reduces the number of modules needed in large-scale systems, optimizing space and cost efficiency. Each channel is individually protected against overvoltage and transient spikes, ensuring long-term reliability even in noisy industrial environments.

Wide Signal Compatibility: The module supports both NPN and PNP input signals, making it versatile for use with a wide range of sensors and switches. Its 24 VDC input range is compatible with standard industrial field devices, eliminating the need for additional signal conditioning hardware. This flexibility simplifies system design and integration, particularly in multi-vendor environments.

Advanced Diagnostic Capabilities: Built-in LED indicators for each channel provide real-time status feedback (e.g., signal presence, fault conditions), enabling quick identification of faulty inputs. The module also communicates diagnostic data to the PLC controller, such as channel voltage levels and noise interference, allowing for proactive maintenance and reducing mean time to repair (MTTR).

Rugged Industrial Design: Constructed with a reinforced plastic enclosure and conformal-coated PCBs, the GE IC660EBD025 resists dust, moisture, and electromagnetic interference (EMI). Its wide operating temperature range (0°C to +60°C) and tolerance for vibration (5–500 Hz, 2 g) make it suitable for harsh environments, including manufacturing plants, power substations, and oil refineries.

Seamless System Integration: As part of GE’s Series 600 PLC platform, the GE IC660EBD025 integrates seamlessly with other modules (e.g., output modules, communication gateways) and GE’s proprietary software. This compatibility ensures a unified control architecture, enabling engineers to configure, monitor, and troubleshoot the system from a single interface.

Application Areas

The GE IC660EBD025 is widely deployed in industries that rely on precise discrete signal monitoring and control:

-

Manufacturing:

- Production Lines: Monitors limit switches, proximity sensors, and safety interlocks in automotive assembly plants, ensuring proper machine alignment and preventing collisions.

- Robotics: Processes digital signals from robotic arms to coordinate movements, track position, and trigger safety stops, enhancing production efficiency and quality control.

-

Power Generation:

- Switchgear Monitoring: Tracks the status of circuit breakers, relays, and contactors in power substations, enabling real-time diagnostics and preventive maintenance.

- Turbine Control: Acquires discrete signals from temperature switches and pressure sensors in steam or gas turbines, supporting safe and efficient power generation.

-

Oil and Gas:

- Pipeline Systems: Monitors valve positions, flow switches, and emergency shutdown (ESD) signals in upstream and downstream processes, ensuring regulatory compliance and operational safety.

- Refineries: Processes digital inputs from level sensors and pressure switches in storage tanks, enabling precise inventory management and leak detection.

-

Water/Wastewater Treatment:

- Pump Stations: Tracks the status of pump motors, flow meters, and gate valves, ensuring consistent water supply and wastewater treatment efficiency.

- Process Control: Acquires signals from level sensors and pH switches in treatment plants, supporting automated chemical dosing and quality control.

Related Products

- GE IC660EBD015: A 32-channel digital input module with similar specifications, ideal for high-density signal acquisition in large-scale systems.

- GE IC660EBD035: A 16-channel digital output module that complements the GE IC660EBD025 by providing discrete signal output capabilities for actuators and relays.

- GE IC660BBD100: A power supply module for GE Series 600 racks, ensuring stable 24 VDC power delivery to the GE IC660EBD025 and other modules.

- GE IC660CBL001: A rack-mounting cable kit designed for seamless integration of the GE IC660EBD025 into GE’s modular control systems.

- GE IC693MDL330: A discrete input module for GE’s 90-30 PLC platform, serving as an alternative for legacy system upgrades.

- GE IC695MDL640: A high-speed digital input module with enhanced response time, suitable for applications requiring rapid signal processing.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IC660EBD025, ensure the following:

Before installing the GE IC660EBD025, ensure the following:

- Verify the power supply voltage (24 VDC ±10%) and confirm that the control rack is properly grounded to prevent electrostatic discharge (ESD) and electrical noise interference.

- Use GE’s Proficy Machine Edition software to configure the module’s address and input parameters, ensuring compatibility with the PLC controller.

- Secure the module in a GE Series 600 rack using the provided mounting brackets, ensuring proper alignment with the backplane connectors.

Maintenance Recommendations:

- Routine Inspections: Check the module’s LED indicators weekly to confirm normal operation. A steady green light indicates a valid input signal, while a flashing light may signal a fault or noise interference.

- Signal Testing: Periodically test each channel using a calibrated signal generator to ensure accurate signal acquisition. Replace faulty channels immediately to maintain system reliability.

- Environmental Maintenance: Clean dust and debris from the module’s vents monthly, especially in dusty environments, to prevent overheating. Monitor ambient temperature and humidity to ensure they remain within specified ranges.

- Firmware Updates: Update the module’s firmware via GE’s software tools when new versions are released, ensuring access to the latest features and security patches.

Product Warranty

Our company provides a one-year quality warranty for the GE IC660EBD025, covering all non-human-induced hardware defects. During the warranty period, if the product exhibits abnormal signal acquisition, channel failures, or physical defects, we will provide prompt replacement services. For discontinued models like the GE IC660EBD025, our extensive global inventory of legacy industrial control parts ensures fast delivery for urgent orders. We also offer post-warranty technical support and repair services through our network of certified technicians, dedicated to keeping your critical systems operational and reliable over the long term.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from GE’s official specifications and industry applications. For detailed operational guidelines, refer to the GE IC660EBD025 user manual or contact our technical support team for personalized assistance.

GE IS200JPDMG1ACC S1AT005 Output module digit

GE IS200TSVCH1AED PXI module

GE IS200TRPGH1BDD S1C5029 Servo drive

GE IS200TTURH1CCC S1DF00Z Eddy current sensor

GE IS200TRLYH1BGF monitor

GE CK11CE300 Safety system

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

GE IS200JPDMG1ACC S1AT005 PDP panel

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: